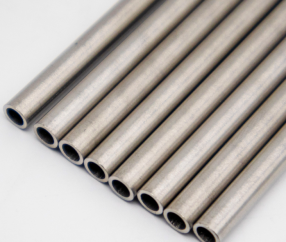

Invar36 Tube 4J36 Expansion Alloy Pipe

Release time:2026-01-02 Strike:887 Inquire Now

What is Invar36?

Invar 36, ultra-low expansion coefficient alloy, is a 36% nickel-iron alloy with a rate of thermal expansion approximately one-tenth that of carbon steel at temperatures up to 400°F (204°C). This alloy is used for applications where dimensional changes due to temperature variation must be minimized or in conjunction with high expansion alloys in applications where a motion is desired when the temperature changes.

Different names of Invar36

| Russia | China | USA | France | Germany | Japan |

| 36H | 4J36 | Invar36 | Invar Standard | Vacodil36 | Cactus LE |

Expansion alloys are precision alloys with anomalous thermal expansion properties, also known as thermal expansion alloys. They are widely used in the electronics industry, precision measuring instruments, precision instruments, and cryogenic engineering. Generally, metals and alloys expand when heated, with the amount of expansion increasing linearly with temperature. However, some alloys exhibit a bending point in their thermal expansion curve at a certain temperature. Below this bending point, the thermal expansion coefficient is much lower than the normal thermal expansion coefficient above the bending point. This phenomenon is known as anomalous thermal expansion properties.

Expansion alloys are divided into low expansion alloys and constant expansion alloys, the latter also known as sealing alloys. Low expansion alloys have an average expansion coefficient below 3×10⁻⁶°C⁻¹ below the bending point, while constant expansion alloys have an average expansion coefficient of approximately (4 to 10)×10⁻⁶°C⁻¹ below the bending point. Major expansion alloys include Fe-Ni series, Fe-Ni-Co series, and Fe-Ni-Cr series alloys. High chromium steel and Co-Fe-Cr series alloys are also used as expansion alloys, but in smaller quantities.

In addition to having specific thermal expansion coefficients, expansion alloys also require good sealing properties, weldability, corrosion resistance, machinability, and ease of cutting, depending on their intended use. They must not undergo phase transformations that significantly alter their expansion properties within their operating temperature range. During the manufacturing process, the chemical composition of expansion alloys must be precisely controlled. The products are generally available in the form of bars, sheets, strips, wires, and tubes.

Invar36 Chemical Composition

| Grade | C | S | P | Mn | Si | Ni | Cr | Co | Cu | Mo | Se | B | Fe |

| 4J36 | ≦0.05 | ≦0.02 | ≦0.020 | 0.2-0.6 | ≦0.3 | 35.0-37.0 | - | - | - | - | - | - | Bal |

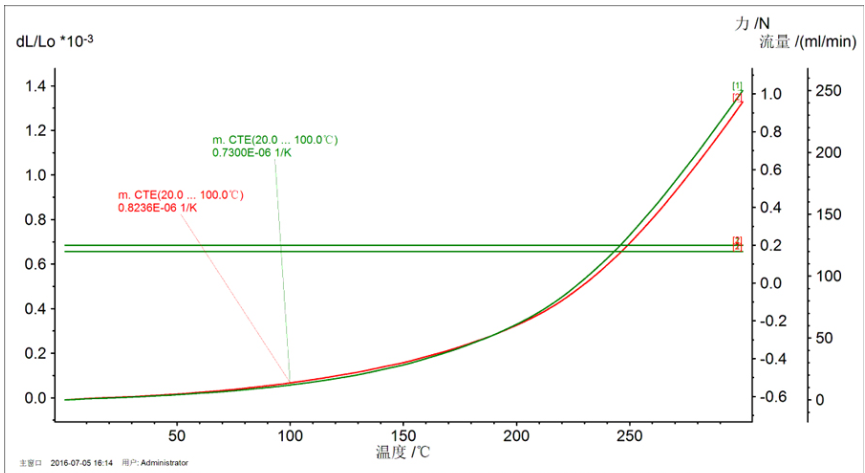

Invar36 Expansion Coefficient Chart

By this chart, we can tell in the temperature range of 0°C-100°C, its expansion is very low.

How much does Invar36 expand in different temperature ranges? Here is our tested data of our Invar36 pipe

| Temperature Range(°C) | Expansion Scale(10-3) | Ave Coefficient (10-6/°C) |

| -200-20 | -0.33 | 1.5 |

| -100-20 | -0.16 | 1.3 |

| 20-100 | 0.12 | 1.5 |

| 20-150 | 0.26 | 2.0 |

| 20-200 | 0.47 | 2.6 |

| 20-250 | 0.8 | 3.5 |

| 20-300 | 1.54 | 5.5 |

| 20-400 | 3.19 | 7.2 |

| 20-450 | 4.01 | 9.3 |

| 20-500 | 4.85 | 10.1 |

-

0.5mm*80mm 4J50 Iron Nickel Strip Features

Density and thermal physical properties of 4J50 iron-nickel prec...

-

Factory Directly Supply 1J90 Precision Alloy Production Method

...

-

1J50 Precision Alloy Plate

1J50 Alloy Plate chemical Composition...

-

Low Core Loss1J33 Soft Magnetic Alloy Pipe

Soft Magnetic Alloy 1J33 : A Versatile Solution for Electromagne...