Factory Directly Supply 1J90 Precision Alloy Production Method

Release time:2025-12-26 Strike:854 Inquire Now

1J90 Alloy Chemical Composition

| Grade | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe |

| 1J90 | ≦0.03 | ≦0.02 | ≦0.02 | ≦0.6 | ≦0.3 | 79-80 | - | - | 1.8-2.2 | - | 0.4-0.6 | 4.8-7.2 | Bal |

Physical and Chemical Properties:

- The 1J90 alloy is an iron-based superalloy, with the primary alloying elements being iron, nickel, and cobalt.

- It has an exceptionally high tensile strength, typically in the range of 1300-1500 MPa.

- The alloy exhibits excellent high-temperature strength and creep resistance, maintaining its mechanical properties even at elevated temperatures.

- 1J90 alloy has good corrosion and oxidation resistance, making it suitable for use in harsh environments.

- The density of the 1J90 alloy is around 8.2 g/cm³, which is slightly higher than some other high-performance alloys.

Production Method:

- 1J90 alloy is commonly produced using vacuum induction melting or vacuum arc remelting processes.

- These methods allow for precise control over the alloy composition and impurity levels, ensuring consistent quality.

- After the initial melting, the alloy may undergo various heat treatment and mechanical processing steps, such as forging, rolling, or casting, to achieve the desired microstructure and properties.

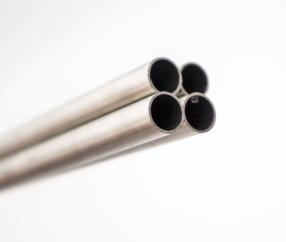

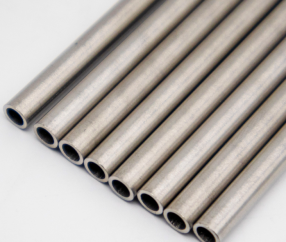

Hot Forging in our workshop

Applications:

- The 1J90 alloy finds widespread use in the aerospace industry, particularly in the manufacture of turbine blades, discs, and other critical engine components.

- It is also employed in the production of high-strength fasteners, springs, and other structural components for aerospace and industrial applications.

- Due to its excellent high-temperature performance, the 1J90 alloy is used in the construction of hot-section components in gas turbines and other power generation equipment.

- Additionally, the alloy's corrosion resistance makes it suitable for use in chemical processing equipment and marine environments.

The 1J87/1J88/1J89/1J91 Alloy have the similar properties.

Advantages of 1J90 Alloy:

1. Exceptional Strength and Hardness:

- The 1J90 alloy's tensile strength, typically ranging from 1300 to 1500 MPa, is exceptionally high, making it an ideal choice for applications requiring extreme mechanical loads.

- Its high hardness, often in the range of 40-50 HRC, provides excellent wear resistance and the ability to withstand severe operating conditions.

2. Excellent High-Temperature Performance:

- The 1J90 alloy maintains its exceptional mechanical properties even at elevated temperatures, making it suitable for use in high-heat applications.

- This characteristic is crucial in the aerospace and power generation industries, where components are subjected to extreme thermal stresses.

3. Corrosion and Oxidation Resistance:

- The 1J90 alloy exhibits excellent resistance to corrosion and oxidation, allowing it to withstand exposure to harsh environments.

- This property extends the service life of components made from the 1J90 alloy, reducing maintenance and replacement costs.

4. Versatile Applications:

- The 1J90 alloy's combination of high strength, high-temperature performance, and corrosion resistance makes it a versatile material suitable for a wide range of industrial and engineering applications.

- From aerospace components to power generation equipment, the 1J90 alloy can be utilized in demanding environments where superior material properties are required.

Overall, the 1J90 alloy is a high-performance superalloy that offers exceptional strength, thermal stability, and corrosion resistance, making it a valuable material in various industries requiring advanced engineering solutions.

-

0.5mm*80mm 4J50 Iron Nickel Strip Features

Density and thermal physical properties of 4J50 iron-nickel prec...

-

Invar36 Tube 4J36 Expansion Alloy Pipe

What is Invar36?Invar 36, ultra-low expansion coefficient alloy,...

-

1J50 Precision Alloy Plate

1J50 Alloy Plate chemical Composition...

-

Low Core Loss1J33 Soft Magnetic Alloy Pipe

Soft Magnetic Alloy 1J33 : A Versatile Solution for Electromagne...