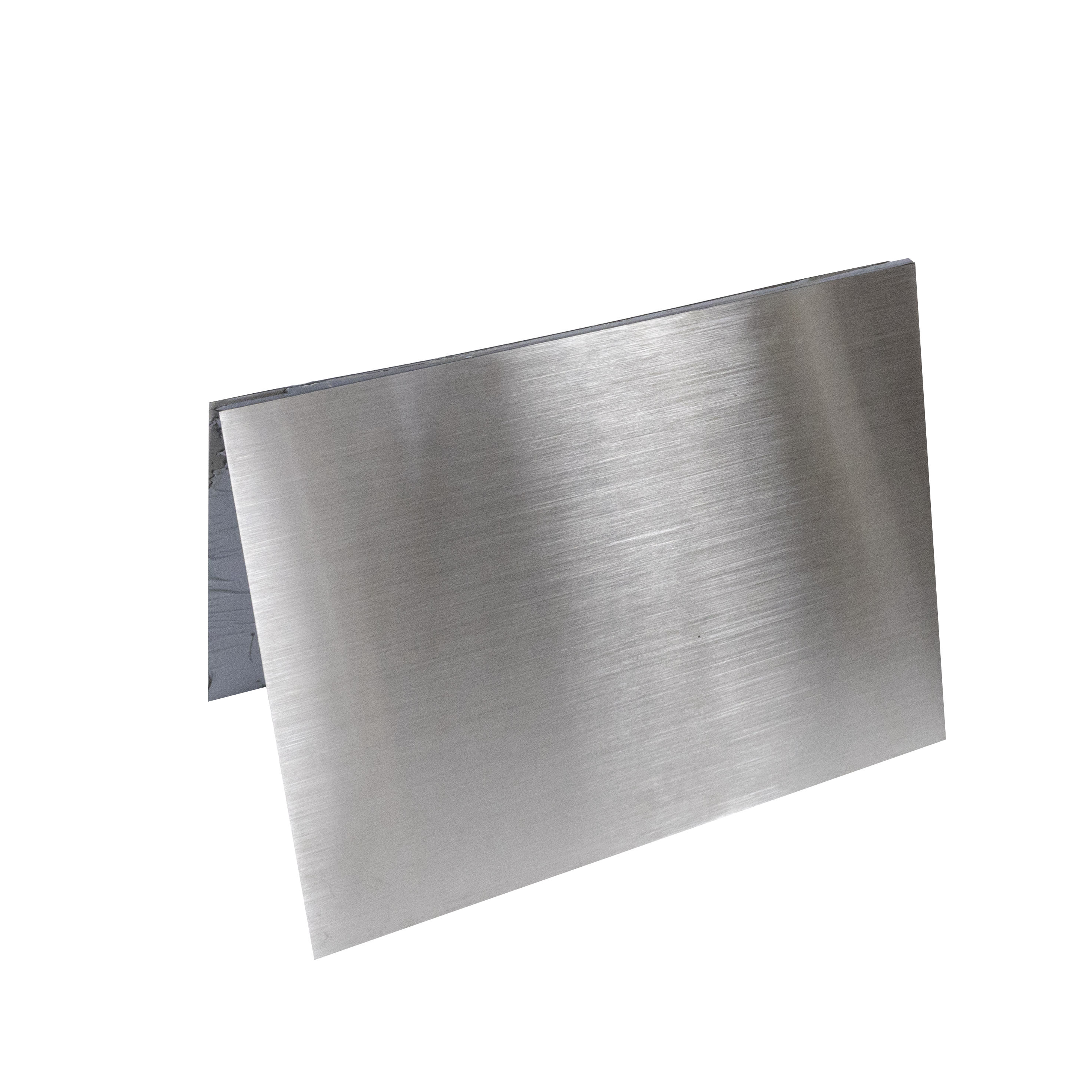

1J50 Precision Alloy Plate

Release time:2025-03-09 Strike:145 Inquire Now

1J50 Alloy Plate chemical Composition

| Grade | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe |

| 1J50 | ≦0.03 | ≦0.02 | ≦0.02 | 0.3-0.6 | 0.15-0.3 | 49.0-50.5 | - | - | - | ≦0.2 | - | - | Bal |

Physical and Chemical Properties:

- 1J50 alloy is an iron-based alloy, with the main components being iron, nickel, and cobalt.

- It has excellent corrosion resistance, high-temperature resistance, and wear resistance.

- The density of the alloy is relatively low, around 7.9 g/cm³.

- The alloy has good electrical and thermal conductivity.

- The tensile strength of 1J50 alloy can reach around 1050 MPa, with a hardness of 35-45 HRC.

Production Method:

- 1J50 alloy is typically produced using vacuum induction melting or electric arc furnace steelmaking.

- During the melting process, the alloy composition and impurity content need to be strictly controlled to ensure product quality.

- After production, the alloy undergoes heat treatment and mechanical processing to achieve the required size and performance specifications.

Applications:

- 1J50 alloy has a wide range of applications due to its excellent properties. It is commonly used in:

- Aerospace and defense industries, where its high strength and corrosion resistance are valued.

- Automotive and transportation sectors, for components that require durability and wear resistance.

- Electrical and electronic applications, taking advantage of the alloy's good electrical and thermal conductivity.

- Various industrial equipment and machinery, benefiting from the alloy's overall performance characteristics.

Advantages of 1J50 Alloy:

1. High Strength and Hardness:

- The 1J50 alloy has an impressive tensile strength of around 1050 MPa, making it a very strong and durable material.

- Its hardness, ranging from 35-45 HRC, provides excellent wear resistance and the ability to withstand high mechanical loads.

2. Excellent Corrosion Resistance:

- The 1J50 alloy exhibits outstanding corrosion resistance, making it suitable for applications in harsh environments or where exposure to corrosive substances is a concern.

- This property extends the service life of components made from 1J50 alloy.

3. High-Temperature Resistance:

- The 1J50 alloy can maintain its mechanical properties and performance at elevated temperatures, making it suitable for use in high-temperature applications.

- This characteristic is particularly valuable in aerospace, automotive, and industrial equipment where components are subjected to high temperatures.

4. Good Electrical and Thermal Conductivity:

- The 1J50 alloy has favorable electrical and thermal conductivity properties, which can be beneficial in electrical and electronic applications.

- This allows for efficient heat dissipation and electrical signal transmission in components made from this alloy.

5. Low Density:

- With a density of around 7.9 g/cm³, the 1J50 alloy is relatively lightweight compared to other high-performance alloys.

- This low density can be advantageous in applications where weight reduction is desirable, such as in aerospace and transportation industries.

These combined advantages make the 1J50 alloy a versatile and high-performance material suitable for a wide range of industrial and engineering applications.

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

Difference Between Kovar and Invar 36

...

0.5mm*80mm 4J50 Iron Nickel Strip Features

Density and thermal physical properties of 4J50 iron-nickel prec...

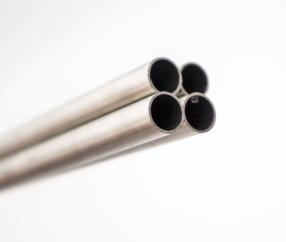

Invar36 Tube 4J36 Expansion Alloy Pipe

What is Invar36?Invar 36, ultra-low expansion coefficient alloy,...

Factory Directly Supply 1J90 Precision Alloy Production Method

...