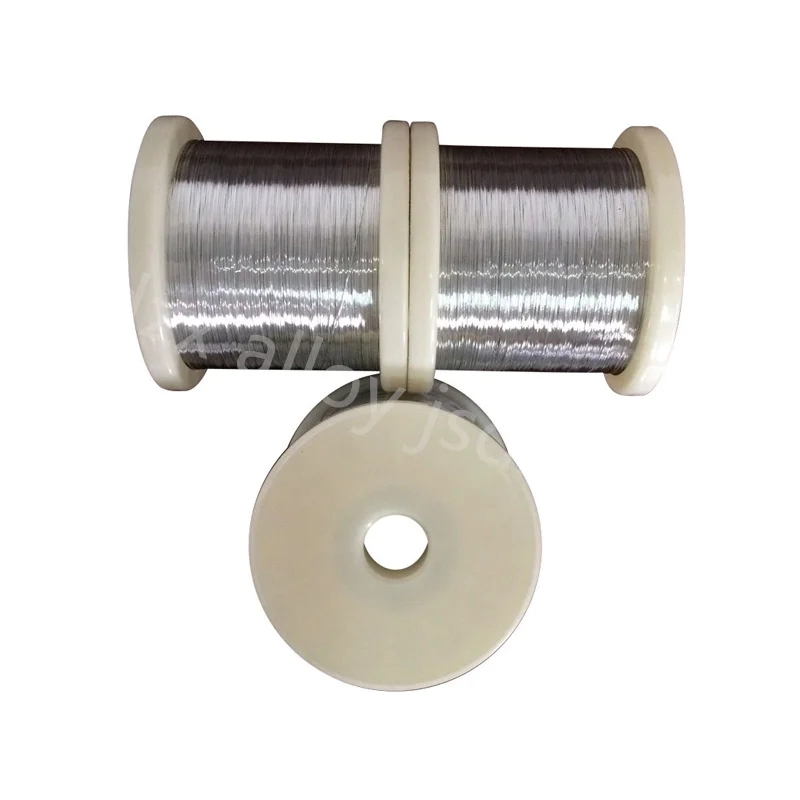

Metal PTC Wire Temperature control in industrial processes for sale

| Product Details | |

| Place Of Origin | China JiangSu |

Brand Name | DLX |

Model Number | PTC Wire |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Metal PTC (Positive Temperature Coefficient) wires, unlike their ceramic counterparts, are not commonly used for temperature sensing due to their primary function as self-regulating Heating Element s rather than sensors. Metal PTC wires, such as those made from alloys like nickel-chromium ( Nichrome ), are designed to increase resistance and limit current flow when heated beyond a specific threshold. Here's an overview of their functionality and potential applications in industrial temperature control:

Metal PTC Wire for Temperature Control in Industrial Processes

Functionality

Self-Regulating Heating Elements:

Metal PTC wires are primarily used as self-regulating heating elements in industrial applications.

As temperature increases, the resistance of the PTC wire also increases, which in turn reduces the current flowing through the wire.

This self-regulating property allows the PTC wire to maintain a constant temperature or prevent overheating without requiring external temperature sensors or controllers.

Temperature Stability:

Metal PTC wires are designed to stabilize at a specific temperature range, providing consistent heating without the need for additional temperature control mechanisms.

They offer inherent temperature limiting capabilities, making them suitable for applications where precise temperature control is not critical but maintaining a maximum temperature threshold is essential.

Applications in Industrial Processes

Process Heating and Control:

Industrial Furnaces: Used in heating elements for furnaces and kilns where maintaining a stable temperature is crucial for material processing.

Plastic Molding: Applied in injection molding and extrusion machines to heat molds and control the temperature of molten plastic.

Food Processing: Used in ovens and heaters for baking, drying, and cooking processes in food manufacturing.

Environmental Control Systems:

HVAC Systems: Integrated into electric heaters and heat pumps to regulate indoor temperatures in commercial and residential buildings.

Climate Chambers: Used in environmental test chambers and climate-controlled rooms to maintain specific temperature conditions for testing and research purposes.

Automotive and Aerospace Applications:

Engine Compartment Heating: Metal PTC wires are employed in engine compartment heaters to prevent freezing and ensure engine start-up in cold weather conditions.

Aircraft De-icing: Used in heating systems for de-icing aircraft components, such as wings and engines, during winter operations.

Consumer Electronics:

Home Appliances: Metal PTC wires are found in heating elements for appliances like electric kettles, coffee makers, and hair dryers, providing controlled heating without external temperature control.

Benefits of Metal PTC Wire for Temperature Control

Self-Regulating: Automatically adjusts heating power based on the ambient temperature, reducing the risk of overheating.

Reliability: Provides consistent performance and operational reliability in diverse industrial and consumer applications.

Simplicity: Simplifies system design by eliminating the need for complex temperature control circuits or sensors.

Summary

While metal PTC wires are primarily utilized as self-regulating heating elements rather than temperature sensors, they play a crucial role in industrial temperature control applications. Their self-regulating properties and robust performance make them suitable for maintaining stable temperatures in various industrial processes, HVAC systems, and consumer appliances. For precise temperature sensing applications, ceramic PTC wires or other types of temperature sensors are typically preferred due to their specific temperature-resistance characteristics and sensitivity.

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

Q:How do you handle pre-sales and post-sales?

A:We have a professional business team that will work one-on-one with you to protect your product needs, and if you have any questions, he can answer them for you!

Q:Can I visit your factory before we place an order?

A:Yes, you are welcome to visit our factory. We are very pleased if we have the chance to know more about each other.

Q:Where can I find up-to-date information about the company?

A:You can check our news or blog for information about our company.

Q:Do the products meet quality standards?

A:All of our products meet quality standards. If you need a certificate for a specific country, we have a professional business team that will work with you one-on-one and can answer any questions you may have!

Q:Where are your production facilities located?

A:We manufacture our products in China and arrange for them to be shipped from China to your country as soon as possible, which usually depends on your product requirements and quantities.