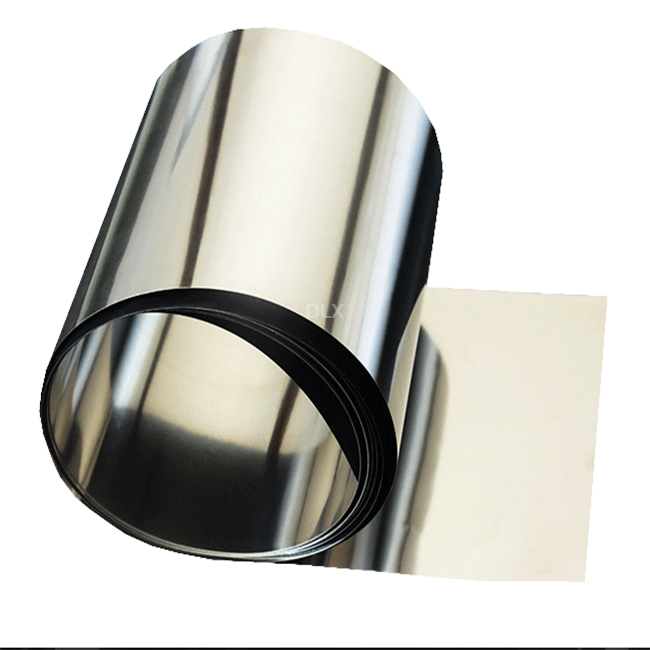

Permanent magnetic alloys Alnico Strip Details and Applications

Release time:2025-03-09 Strike:159 Inquire Now

Alnico (an acronym for Aluminum, Nickel, and Cobalt) alloys are a group of permanent magnetic materials that are made primarily from aluminum (Al), nickel (Ni), and cobalt (Co), with iron (Fe) as the primary ingredient and varying amounts of other elements like copper (Cu) and titanium (Ti). Alnico magnets are known for their excellent temperature stability and high residual induction. Here are some common grades of Alnico alloys:

| Grade | C | S | P | Mn | Si | Ni | Cr | Co | V | Mo | W | Fe |

| 2J9 | ≦0.12 | ≦0.02 | ≦0.025 | ≦0.7 | ≦0.7 | ≦0.7 | - | 51-53 | 8.5-9.5 | - | - | Bal |

Common Grades of Alnico Alloys

Alnico 1:

Composition: Approximately 12% Al, 24% Ni, 8% Co, balance Fe.

Characteristics: High coercivity and moderate magnetic strength.

Alnico 2:

Composition: Approximately 10% Al, 19% Ni, 13% Co, 3% Cu, balance Fe.

Characteristics: Higher magnetic strength than Alnico 1, commonly used in musical instrument pickups and other sensors.

Alnico 3:

Composition: Approximately 12% Al, 25% Ni, 4% Cu, balance Fe.

Characteristics: High magnetic strength and good temperature stability.

Alnico 5:

Composition: Approximately 8% Al, 14% Ni, 24% Co, 3% Cu, balance Fe.

Characteristics: One of the most widely used Alnico magnets with high magnetic strength and good stability, commonly used in motors, sensors, and loudspeakers.

Alnico 6:

Composition: Similar to Alnico 5 with slight variations.

Characteristics: Higher coercivity and temperature stability compared to Alnico 5.

Alnico 8:

Composition: Approximately 7% Al, 15% Ni, 35% Co, 5% Cu, balance Fe.

Characteristics: Highest coercivity among the Alnico grades, used in applications requiring resistance to demagnetization and high-temperature stability.

Key Properties of Alnico Magnets

High Magnetic Strength: Alnico magnets have a high remanence (residual magnetism) which makes them strong permanent magnets.

Temperature Stability: They can operate at temperatures up to 550°C (1022°F) without significant loss of magnetic properties.

Corrosion Resistance: Alnico magnets are relatively resistant to corrosion, but they can be surface-coated for additional protection in harsh environments.

Brittleness: Alnico magnets are relatively brittle and can be easily damaged if not handled with care.

Applications of Alnico Magnets

Electric Motors: Used in various types of motors for their strong magnetic fields.

Sensors: Commonly used in sensors and actuators due to their stability and reliability.

Loudspeakers: Utilized in loudspeakers for their ability to produce strong and consistent magnetic fields.

Musical Instruments: Frequently used in guitar pickups and other musical instruments for their reliable magnetic properties.

Magnetic Assemblies: Employed in holding and lifting applications where strong and stable magnetic fields are required.

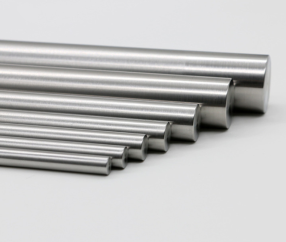

Hard magnetic material 2J9 Rods and its Testing machine

Hard magnetic material, which is also known as Permanent Magneti...

P6 Alloy 2J4 Hysteresis Alloy

2J4 (2J04 is an iron-cobalt-nickel-vanadium hysteresis alloy wi...

2J07 Permanent Magnetic Alloy

Permanent magnetic alloys, also known as hard magnetic materials...