Elasticity nichrome Heating Element s Yield Strength 200-300 MPa Resistance Strip for sale

| Product Details | |

| Place Of Origin | China |

Brand Name | DLX |

Model Number | Nichrome |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

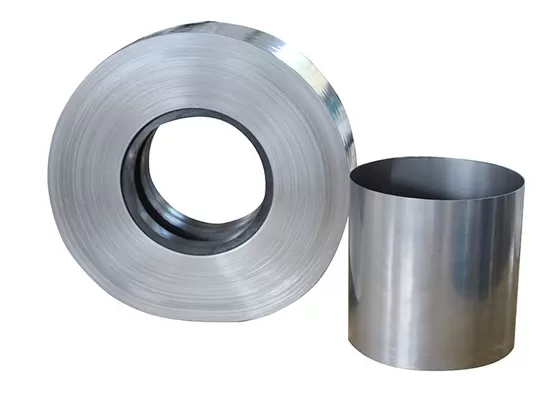

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Product Description:

The Nichrome Alloy has a hardness rating of HV400-500, which makes it highly resistant to wear and tear. This attribute ensures that the material can withstand high temperatures and maintain its shape and structure over time. Additionally, the yield strength of the alloy falls within the range of 200-300 MPa, which shows that it has a high resistance to deformation and can handle heavy loads.

Another important feature of the Nichrome Alloy is its exceptional thermal conductivity, which measures between 15-20 W/mK. This attribute signifies that the material can efficiently transfer heat from one point to another, making it an ideal choice for heating elements and furnaces. Furthermore, the thermal expansion coefficient of the Nichrome Alloy is measured between 13-17 μm/mK, indicating that the material can withstand significant temperature changes without cracking or breaking.

One of the primary uses of the Nichrome Alloy is in the creation of Nichrome wire, which is a popular type of resistance wire. This wire is widely used in the manufacturing of heating elements for various industrial applications. It is highly resistant to corrosion and can endure high temperatures for extended periods. Nichrome wire is also a popular choice in the production of electrical components such as resistors, circuit breakers, and fuses.

In conclusion, the Nichrome Alloy is a versatile material that offers exceptional durability, heat resistance, and electrical conductivity. Its unique combination of properties makes it an ideal choice for heating elements, furnaces, and electrical components. The Nichrome wire, which is made from this alloy, is a popular choice for industrial applications due to its high resistance to corrosion and ability to withstand extreme temperatures. If you're looking for a reliable and durable material for your industrial projects, the Nichrome Alloy is an excellent choice.

Features:

Product Name: Nichrome Alloy

Forms: Wire, Sheet, Strip, Rod, Tube

Thermal Expansion: 13-17 μm/mK

Corrosion Resistance: Excellent

Melting Point: 1400-1450°C

Keywords: Nichrome Alloy, Nichrome coil, Cr20Ni80

Technical Parameters:

| Elongation | 20-30% |

| Name | Nichrome Alloy |

| Electrical Resistivity | 1.1-1.2 μΩm |

| Melting Point | 1400-1450°C |

| Applications | Heating Elements, Furnaces, Electrical Components |

| Thermal Expansion | 13-17 μm/mK |

| Magnetic Properties | Non-magnetic |

| Thermal Conductivity | 15-20 W/mK |

| Forms | Wire, Sheet, Strip, Rod, Tube |

| Chemical Composition | Ni-Cr-Fe |

The Nichrome Alloy is commonly used in nichrome coils, nichrome wires and nichrome heating elements.

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1.0 | ≤1.0 | Rest | Rest | Rest | ||

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity(μΩ·m,20℃) | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | ||

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat(J/g.℃) | 0.44 | 0.44 | 0.44 | 0.44 | 0.44 | 0.44 | |

| Thermal conductivity(KJ/m.h℃) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | ||

Coefficient of lines expansion19 (20~1000℃) | 18 | 17 | 17 | 19 | 19 | ||

| Micrographic structure | Austenite | Austenite | Austenite | Austenite | Austenite | ||

| Magnetic properties | onmagnetic | onmagnetic | onmagnetic | onmagnetic | onmagnetic | ||

Applications:

The Nichrome alloy has an elongation of 20-30% and a tensile strength of 400-500 MPa. Its density is 8.4 G/cm3, and its electrical resistivity is 1.1-1.2 μΩm. These attributes make it an ideal choice for a wide range of industrial applications that require a high-quality resistance wire.

The Nichrome coil is a popular product used in the manufacturing of nichrome heating elements. These heating elements are used in various applications, including ovens, furnaces, and heating appliances. The Nichrome wire is also a popular product used in the production of heating elements, as it offers excellent resistance to oxidation and high-temperature corrosion.

The Nichrome alloy is widely used in the manufacturing of heating elements for electric appliances. It is used in various industrial sectors, including the automotive industry, aerospace industry, and electronics industry. The product is known for its excellent thermal stability and high resistance to corrosion, making it a reliable choice for industrial applications.

In conclusion, the DLX Alloy Nichrome is a high-quality resistance wire that is widely used in various industrial applications. Its high-quality attributes make it an ideal choice for nichrome coil, nichrome heating elements, and nichrome wire. The product is reliable, durable, and available in different packaging options, making it a popular choice for industrial applications.

Support and Services:

The Nichrome Alloy product is a high temperature resistant alloy that is commonly used in heating applications such as electric heating elements. Our technical support and services include:

Expert advice on material selection and product design

Customized alloy compositions and specifications

Assistance with product testing and validation

Technical training and guidance on product installation and maintenance

Quality control and assurance processes to ensure product consistency and reliability

Our team of experienced engineers and technicians are dedicated to providing superior technical support and services to ensure the success of your project.

Packing and Shipping:

The Nichrome Alloy product is packaged in a sturdy cardboard box to ensure safe delivery. Inside the box, the product is wrapped in bubble wrap to prevent any damage during transit. The box is labeled with the product name, quantity, and handling instructions.

Shipping:

The Nichrome Alloy product is shipped via a reputable courier service. The shipping cost is calculated based on the weight and destination of the package. Shipping times may vary depending on the location of the customer. Once the package is shipped, a tracking number will be provided to the customer for easy monitoring of the shipment's progress.