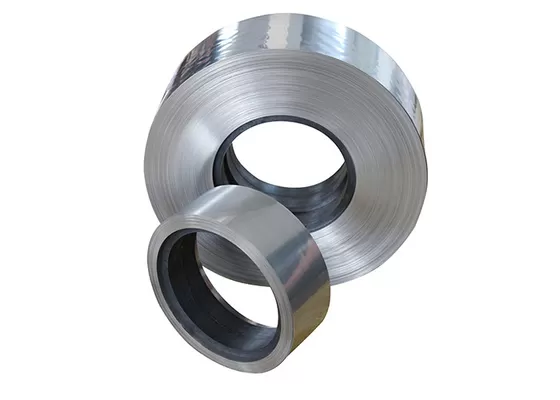

Corrosion Resistant Resistance Strip Nichrome Alloy for sale

| Product Details | |

| Place Of Origin | China |

Brand Name | DLX |

Model Number | Nichrome |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Product Description:

Nichrome wire is one of the most popular forms of Nichrome Alloy. It is widely used in the Heating Element industry. Nichrome wire is known for its high electrical resistivity, which is between 1.1-1.2 μΩm. This makes it an ideal material for heating elements, as it can withstand high temperatures and maintain its resistance. Nichrome wire is also known for its high tensile strength, which ranges from 400-500 MPa. This makes it a durable and reliable material for various applications.

Nichrome coil is another popular form of Nichrome Alloy. It is widely used in the vaping industry. Nichrome coil is known for its excellent thermal expansion properties, which range from 13-17 μm/mK. This makes it an ideal material for heating coils, as it can expand and contract with temperature changes. Nichrome coil is also known for its high elongation, which ranges from 20-30%. This makes it a flexible and stretchable material that can withstand repeated use.

The Nichrome Alloy is also used in the production of various other products, such as resistance wires, ribbon wires, and flat wires. These products are widely used in the electronics industry, as they have excellent electrical and thermal properties. The Nichrome Alloy is also used in the production of various industrial heaters, such as furnaces and ovens. It is an excellent material for these applications, as it can withstand high temperatures and maintain its resistance over a long period of time.

In conclusion, the Nichrome Alloy is a versatile and reliable material that is widely used in various industries. Its high electrical resistivity, tensile strength, thermal expansion, and elongation make it an ideal material for many applications. Whether you are looking for Nichrome wire, Nichrome coil, or other forms of Nichrome Alloy, you can be sure that you are getting a high-quality material that will meet your needs and exceed your expectations.

Features:

Product Name: Nichrome Alloy

Magnetic Properties: Non-magnetic

Electrical Resistivity: 1.1-1.2 μΩm

Thermal Expansion: 13-17 μm/mK

Elongation: 20-30%

Forms:

Wire

Sheet

Strip

Rod

Tube

Cr20Ni80 is a widely used nichrome heating element. Nichrome wire is commonly used for heating applications due to its high resistance to heat and corrosion.

Technical Parameters:

| Attribute | Value |

|---|---|

| Forms | Wire, Sheet, Strip, Rod, Tube |

| Density | 8.4 G/cm3 |

| Applications | Heating Elements, Furnaces, Electrical Components |

| Thermal Expansion | 13-17 μm/mK |

| Name | Nichrome Alloy |

| Melting Point | 1400-1450°C |

| Magnetic Properties | Non-magnetic |

| Hardness | HV400-500 |

| Chemical Composition | Ni-Cr-Fe |

| Elongation | 20-30% |

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1.0 | ≤1.0 | Rest | Rest | Rest | ||

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity(μΩ·m,20℃) | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | ||

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat(J/g.℃) | 0.44 | 0.44 | 0.44 | 0.44 | 0.44 | 0.44 | |

| Thermal conductivity(KJ/m.h℃) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | ||

Coefficient of lines expansion19 (20~1000℃) | 18 | 17 | 17 | 19 | 19 | ||

| Micrographic structure | Austenite | Austenite | Austenite | Austenite | Austenite | ||

| Magnetic properties | onmagnetic | onmagnetic | onmagnetic | onmagnetic | onmagnetic | ||

Applications:

The Nichrome coil is a heating element that is commonly used in industrial and household applications. Its chemical composition consists of Ni-Cr-Fe, with a yield strength of 200-300 MPa and a thermal conductivity of 15-20 W/mK. With a density of 8.4 G/cm3, this coil is known for its durability and longevity.

The Nichrome coil is ideal for use in furnaces, electrical components, and other heating applications. It is commonly used in the production of heating elements for ovens, toasters, and other household appliances. It is also used in the manufacturing of industrial heating elements for use in various industries such as aerospace, automotive, and electronics.

The Nichrome coil is a versatile product that can be used in various scenarios. It is commonly used in the production of electric heating elements, such as toaster coils, and in the production of industrial heating elements such as furnace coils. It is also used in the production of heating elements for various household appliances such as ovens and dryers.

Overall, the DLX Alloy Nichrome product is a high-quality, durable, and versatile product that is perfect for various applications. With its chemical composition of Ni-Cr-Fe, yield strength of 200-300 MPa, and thermal conductivity of 15-20 W/mK, it is no wonder why this product is highly sought after. So, if you are looking for a reliable and efficient heating element for your application, consider the Nichrome coil, Cr20Ni80.

Support and Services:

Our product technical support and services for Nichrome Alloy include:

- Assistance with product selection and specification

- Technical guidance on material properties, processing, and applications

- Custom alloy development to meet specific customer requirements

- Product testing and analysis to ensure quality and performance

- Troubleshooting support for any issues that may arise

Packing and Shipping:

Product Packaging:

Our Nichrome Alloy product is carefully packaged to ensure it arrives at your doorstep in perfect condition. It is packed in a sturdy cardboard box with ample padding to prevent any damage during transit.

Shipping:

We offer worldwide shipping for our Nichrome Alloy product. Our standard shipping method is through reputable courier services, such as DHL or FedEx, which usually takes 7-14 business days to arrive at your location. We also offer expedited shipping options for urgent orders.

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.