List of Industrial Heating Materials

- Product Details

Comprehensive List of Industrial Heating Materials

Industrial heating materials are chosen based on factors such as operating temperature, electrical resistance, durability, and environmental conditions. These materials are commonly used in furnaces, heating elements, resistance wires, and thermal processing industries.

1️⃣ Metallic Heating Materials

These materials have high electrical resistance, good oxidation resistance, and long service life in industrial heating applications.

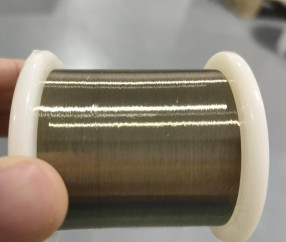

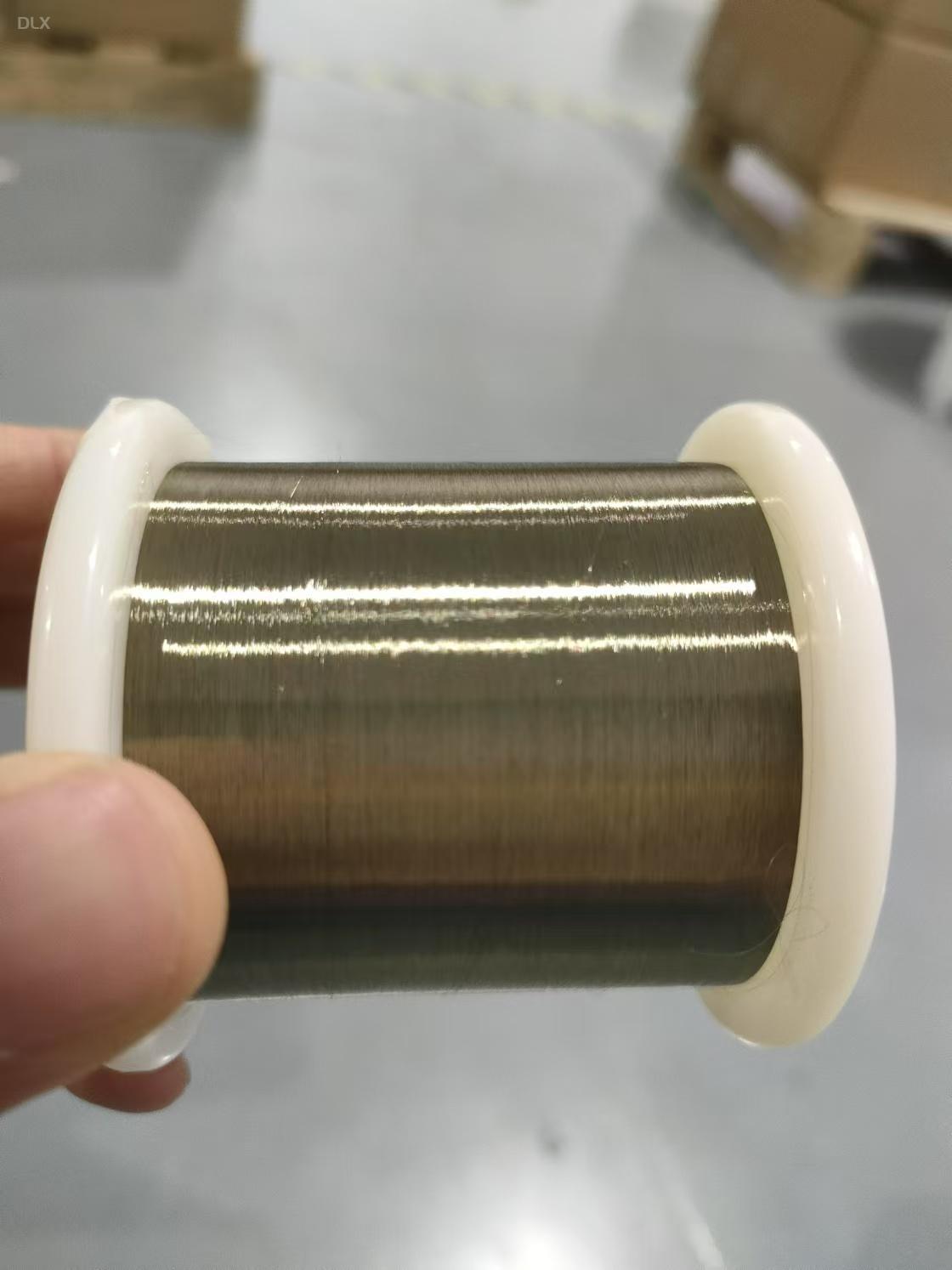

Nickel-Based Alloys

Nichrome (NiCr) Alloys

Common Grades: Ni80Cr20, Ni60Cr15, Ni35Cr20

Features: High electrical resistance, excellent oxidation resistance, long service life

Applications: Electric heating elements, toasters, furnaces, industrial heaters

Iron-Chromium-Aluminum ( FeCrAl ) Alloys

Common Grades: FeCrAl (e.g., Kanthal A-1, APM)

Features: Higher maximum temperature than Nichrome, better oxidation resistance

Applications: High-temperature furnaces, metal heat treatment, ceramic kilns

Superalloys (Inconel, Hastelloy, Haynes, etc.)

Common Grades: Inconel 600, Inconel 625, Hastelloy X

Features: Corrosion resistance, high-temperature strength, oxidation resistance

Applications: Aerospace, gas turbines, chemical industries

Tungsten & Molybdenum-Based Materials

Tungsten (W) & Tungsten Alloys

Features: Highest melting point (3422°C), excellent thermal conductivity

Applications: High-temperature furnaces, aerospace heating elements, vacuum heating

Molybdenum (Mo) & Molybdenum Disilicide (MoSi₂)

Common Grades: MoSi₂ (Kanthal Super)

Features: Operates at ~1800°C, high oxidation resistance

Applications: High-temperature industrial furnaces, glass and ceramic kilns

Tantalum (Ta) & Rhenium (Re)

Features: High corrosion resistance, stability in vacuum

Applications: Specialty furnaces, space applications

2️⃣ Ceramic & Composite Heating Materials

Used for high-temperature stability and insulating properties in industrial heating applications.

Silicon Carbide (SiC) Heating Elements

Features: High electrical resistivity, operates at ~1600°C, self-healing oxidation layer

Applications: Kilns, glass processing, metal melting

Alumina (Al₂O₃) & Zirconia (ZrO₂) Heating Materials

Features: High melting point, electrically insulating

Applications: Used in heating rods, insulation for metal heating elements

Graphite & Carbon-Based Heating Materials

Graphite Rods & Carbon Fiber Heating Elements

Features: High electrical conductivity, stability in inert atmospheres, vacuum furnaces

Applications: High-temperature vacuum furnaces, semiconductor processing

Cermet Materials (Ceramic-Metal Composites)

Features: Combination of metallic conductivity and ceramic heat resistance

Applications: Specialty heating elements

3️⃣ Gas & Liquid Heating Materials

Some industrial heating applications require chemical combustion-based materials instead of electric heating elements.

Hydrogen, Natural Gas, and Propane Combustion

Applications: Large-scale industrial boilers, glass manufacturing, metal smelting

Molten Salts (Eutectic Salt Bath Heaters)

Features: High heat transfer efficiency, stable at 500–900°C

Applications: Heat treatment furnaces, aluminum casting

4️⃣ Emerging & Advanced Heating Materials

New nanomaterials and composites are being developed to improve efficiency and temperature control.

Carbon Nanotube (CNT) Heating Films

Features: Rapid heating, energy-efficient, flexible

Applications: Wearable heating, industrial sensors

Plasma & Induction Heating Coils

Features: Uses electromagnetic fields to generate heat without direct contact

Applications: Induction furnaces, metal hardening

Summary Table: Industrial Heating Materials & Applications

| Material Type | Common Grades | Max Temperature (°C) | Applications |

|---|---|---|---|

| Nichrome (NiCr) | Ni80Cr20, Ni60Cr15 | ~1200°C | Heating coils, ovens, toasters |

| FeCrAl (Iron-Chrome-Aluminum) | Kanthal A-1, APM | ~1400°C | High-temperature furnaces, kilns |

| Tungsten (W) & Molybdenum (Mo) | Pure W, MoSi₂ | 1800–3000°C | Aerospace, vacuum furnaces |

| Silicon Carbide (SiC) | SiC rods | ~1600°C | Glass, metal processing |

| Graphite & Carbon Materials | Graphite rods | ~3000°C | Vacuum furnaces, semiconductor |

| Gas Heating | Natural Gas, H₂ | Varies | Boilers, metal smelting |

| Molten Salt Heating | NaCl-KCl eutectic | ~900°C | Heat treatment, aluminum casting |

| Carbon Nanotubes (CNTs) | CNT films | ~1000°C | Flexible heaters, sensors |

Would you like specific recommendations for your application? 😊