Product Details

Place Of Origin: China

Brand Name: DLX

Model Number: Cr20Ni80

Payment & Shipping Terms

Minimum Order Quantity: 5

Packaging Details: Spool Package With Carton Box, Coil Package With Polybag For Resistance Wire

Delivery Time: 5-21 Days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 300 Tons Per Month

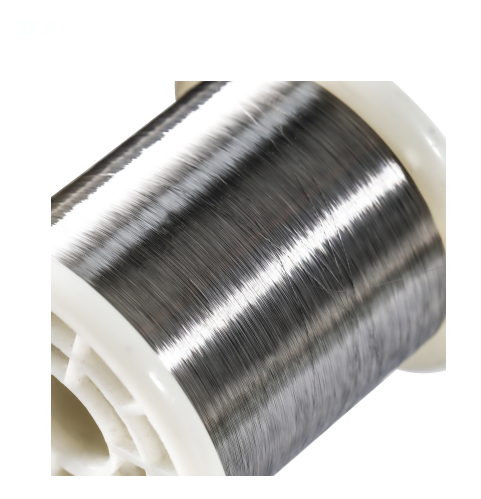

Cr20Ni80 wire, also known as Nichrome 80/20 wire, is an alloy made from 80% nickel and 20% chromium. It is widely used in various industrial applications due to its high resistance to oxidation and corrosion, along with its ability to withstand high temperatures. This alloy wire is commonly utilized in Heating Element s, resistance wire, and other high-temperature applications.

Highlight: Heating Element Cr20Ni80 Resistance Wire, Heating Element Nichrome 80 Resistance Wire, 637MPA NiCr Alloy

Material: | Nickel, Chromium | Nickel(Min): | 77% |

Resistivity: | 1.09+/-0.05 | Tensile Strength: | 637MPA |

Elongtation: | ≥20% | Application: | Heating, Resistivity |

Condition: | Hard / Soft | Sureface: | Bright, Oxided, Acide |

Delivery Time: | 7-20 Days | Name: | Resistance Wire |

High-Temperature Resistance:

Can withstand temperatures up to 1200°C (2192°F) in continuous service, making it ideal for use in high-temperature environments such as furnaces, kilns, and heaters.

Oxidation and Corrosion Resistance:

Exhibits excellent resistance to oxidation in both hot and cold environments, due to the formation of a protective chromium oxide layer.

Resists corrosion in various atmospheric conditions, including moist or humid environments, which extends the lifespan of the wire in demanding settings.

Electrical Resistivity:

Cr20Ni80 has a high electrical resistivity, around 1.09 µΩ·m at 20°C, making it ideal for use in resistance heating applications. The resistivity remains stable over a wide temperature range, ensuring consistent performance.

Mechanical Strength and Stability:

The wire has excellent mechanical strength at elevated temperatures, making it resistant to sagging, warping, or deformation under continuous high heat.

It also maintains good ductility, allowing it to be shaped, bent, or coiled without losing its structural integrity.

Thermal Expansion:

Exhibits moderate thermal expansion, ensuring that it does not expand or contract significantly when exposed to temperature fluctuations, which is critical for precise heating elements and applications.

Key Advantages of Cr20Ni80 Wire:

Consistent Resistance: Offers stable and predictable resistance across a wide range of temperatures.

Durability: Long lifespan due to its resistance to oxidation, corrosion, and thermal fatigue.

High Melting Point: Can handle extremely high temperatures without melting or degrading, making it suitable for demanding thermal applications.

Versatile: Used in a wide range of industries, including manufacturing, electronics, and laboratory environments.

Comparison to Other Alloys:

Compared to lower nickel-chromium alloys (like Cr15Ni60), Cr20Ni80 has better resistance to oxidation, a higher working temperature limit, and greater stability under high-heat conditions.

While more expensive than some alternatives, its longer lifespan and superior performance make it cost-effective in the long run for applications where reliability is crucial.

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1.0 | ≤1.0 | Rest | Rest | Rest | ||

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity(μΩ·m,20℃) | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | ||

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat(J/g.℃) | 0.44 | 0.44 | 0.44 | 0.44 | 0.44 | 0.44 | |

| Thermal conductivity(KJ/m.h℃) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | ||

Coefficient of lines expansion19 (20~1000℃) | 18 | 17 | 17 | 19 | 19 | ||

| Micrographic structure | Austenite | Austenite | Austenite | Austenite | Austenite | ||

| Magnetic properties | onmagnetic | onmagnetic | onmagnetic | onmagnetic | onmagnetic | ||

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.