Premium Ni-Cr-Fe Alloy Nitinol Wire with High Heat Resistance

- Product Details

We’re totally pumped about our premium Ni-Cr-Fe alloy Nitinol wire—it’s a next-level material with killer heat resistance and shape memory that’s perfect for high-performance applications. This wire is designed to shine in industries where heat, flexibility, and reliability are a must.

This Nitinol variant, blending nickel, titanium, chromium, and iron (roughly 50-55% Ni, 40-45% Ti, with small amounts of Cr and Fe), takes the classic Nitinol formula and cranks up the heat resistance to handle temperatures up to 600°C. That’s a step above standard Nitinol, making it ideal for hotter environments like oven elements, aerospace actuators, or medical tools. Its shape memory effect lets it snap back to its original shape when heated, while its superelasticity allows it to stretch like crazy—up to 10-30 times more than regular metals—without staying bent. Plus, with a tensile strength of 900-1900 MPa, it’s tough as nails.

The low magnetic susceptibility (2.5-4 emu/g) is a big win, keeping interference low in sensitive electronics, while its excellent corrosion resistance means it holds up in harsh, high-heat conditions. We can tweak the alloy’s composition to fine-tune transformation temperatures, making it super versatile for custom designs in ovens, medical devices, or industrial systems.

The industry in 2025 is all about smart, durable materials, and our Ni-Cr-Fe Nitinol wire is right on trend. There’s huge demand for components that combine flexibility, heat resistance, and eco-friendliness in medical, aerospace, and appliance manufacturing. Being 100% recyclable, this wire fits perfectly with sustainable production goals. The rise of compact, high-efficiency systems also makes its shape memory and superelasticity a top choice for innovative designs.

Sure, Nichrome Cr20Ni80 can handle higher temperatures (1200°C), but our Ni-Cr-Fe Nitinol’s shape memory and superelasticity make it unbeatable for dynamic applications. Standard Nitinol is great, but the Cr-Fe boost gives our wire an edge in hotter environments. Just avoid extreme fatigue cycles, though it’s tougher than most.

From oven heating elements to cutting-edge medical implants, our Ni-Cr-Fe Nitinol wire brings the heat, flexibility, and durability to keep industries pushing boundaries.

Features:

Product Name: Nichrome Alloy

Name: Nichrome Alloy

Applications:

Heating Elements

Furnaces

Electrical Components

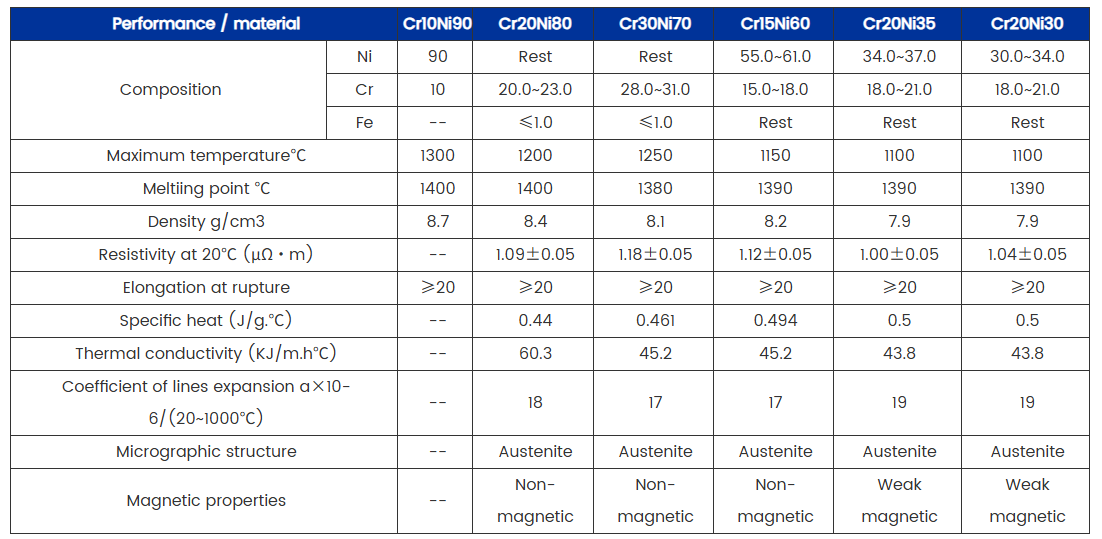

Elongation: 20-30%

Magnetic Properties: Non-magnetic

Thermal Conductivity: 15-20 W/mK

Support and Services:

Nichrome Alloy is a high-resistance, nickel-chromium-based alloy that is commonly used in heating elements. Our technical support and services for this product include:

Assistance with product selection and customization

Guidance on proper installation and usage

Troubleshooting and problem-solving support

Recommendations for maintenance and repair

Training and educational resources for users and installers

Our team of experts is dedicated to helping you get the most out of your Nichrome Alloy product. Contact us for more information or assistance.

Packing and Shipping:

Product Packaging:

The Nichrome Alloy product will be carefully packed in a sturdy cardboard box.

The box will be labeled with the product name, quantity, and any important handling instructions.

Inside the box, the Nichrome Alloy product will be wrapped in protective material to prevent damage during shipping.

Shipping Information:

We offer fast and reliable shipping options to ensure your Nichrome Alloy product arrives on time and in good condition.

Shipping rates will vary depending on the destination and shipping method selected.

We will provide you with a tracking number so you can track your shipment every step of the way.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Why use Ni-Cr-Fe Nitinol wire for high-heat applications?

Its shape memory and heat resistance make it perfect for dynamic, high-temperature systems.

How does Ni-Cr-Fe Nitinol compare to standard Nitinol?

The Cr-Fe addition boosts heat resistance while maintaining shape memory and superelasticity.

Can this wire handle high temperatures?

Yup, it’s stable up to 600°C, great for demanding heating applications.

Is this Nitinol wire corrosion-resistant?

Totally, it resists corrosion even in harsh, high-heat environments.

What’s the benefit of low magnetic interference?

It minimizes disruption in sensitive electronics, ideal for precision applications.

Is this wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in medical devices?

Absolutely, its biocompatibility and flexibility are perfect for implants and tools.

Is Ni-Cr-Fe Nitinol wire cost-effective?

Yes, its durability and unique properties justify the cost for high-value applications.