Excellent Corrosion Resistance Nichrome Wire with High Density 8.4 G/cm3 and Melting Point 1400-145

- Product Details

Our Nichrome Wire has a thermal expansion rate of 13-17 μm/mK, making it an ideal choice for applications where thermal stability is important. This attribute makes it a popular choice for use in heating elements for ovens, furnaces, and other high-temperature applications. Additionally, our Nichrome Wire has excellent electrical conductivity, making it a great choice for use in electrical heating elements and other electrical applications.

Our Nichrome Wire is also non-magnetic, making it a great choice for applications where magnetic properties are not desired. This attribute is particularly important in medical applications, where the use of magnetic materials could interfere with equipment or cause harm to patients. Our Nichrome Wire is a great alternative to Nitinol materials, which are known for their magnetic properties.

Our Nichrome Wire has a high elongation rate of 20-30%, meaning it can be stretched or bent without breaking. This attribute makes it an excellent choice for use in applications where flexibility is important, such as in the creation of springs or other flexible components. Our Nichrome Wire is a great alternative to Nitinol materials, which are known for their flexibility and shape-memory properties.

Overall, our Nichrome Wire product is a top choice for professionals in a wide range of industries. With its excellent thermal stability, electrical conductivity, and non-magnetic properties, it is a great alternative to Nitinol materials. Its high elongation rate also makes it a versatile choice for applications where flexibility is important. Contact us today to learn more about our Nichrome Wire product and how it can benefit your business.

We’re totally pumped about our Nichrome wire, rocking a high density of 8.4 g/cm³, a melting point of 1400-1450°C, and killer corrosion resistance. This wire is a beast for high-temperature applications where reliability and toughness are non-negotiable.

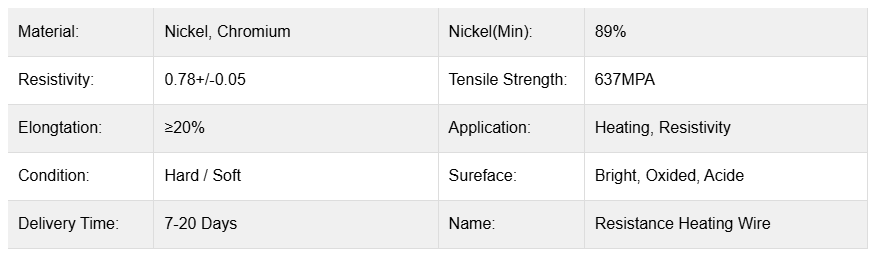

This Nichrome wire, made of 80% nickel and 20% chromium, is built to handle serious heat—stable up to 1200°C with a melting point that keeps it solid even in extreme conditions. Its corrosion resistance is next-level, forming a protective oxide layer that laughs off rust and degradation, making it perfect for harsh environments like industrial furnaces, kilns, or even chemical processing heaters. The high density of 8.4 g/cm³ gives it a robust, solid feel, ensuring it holds up under stress.

With a tensile strength around 650 MPa and a steady electrical resistivity of about 1.09 µΩ·m, this wire delivers consistent, efficient heat for years, cutting down on maintenance hassles. It’s also super formable—we can coil, twist, or shape it into custom heating elements to fit any setup, from big industrial systems to smaller appliance heaters.

The industry in 2025 is all about durable, efficient materials, and our Nichrome wire is right on trend. There’s a huge push for components that can withstand high heat and corrosion while keeping costs reasonable, especially in sectors like metalworking, ceramics, and industrial manufacturing. Being 100% recyclable, it’s a great fit for eco-conscious production goals. As automated, high-precision heating systems keep growing, this wire’s reliability and corrosion resistance make it a top choice.

Sure, FeCrAl alloys like Kanthal A-1 can push slightly higher temperatures, but our Nichrome wire’s corrosion resistance and high density give it an edge in environments where longevity and toughness matter most. CuNi44 Constantan is cheaper but can’t handle the heat like Nichrome. Just steer clear of extreme reducing atmospheres, though this wire handles most conditions like a pro.

From heavy-duty furnaces to precision heating elements, our Nichrome wire with 8.4 g/cm³ density and 1400-1450°C melting point delivers the durability, corrosion resistance, and heat performance that keep industries firing on all cylinders.

Applications:

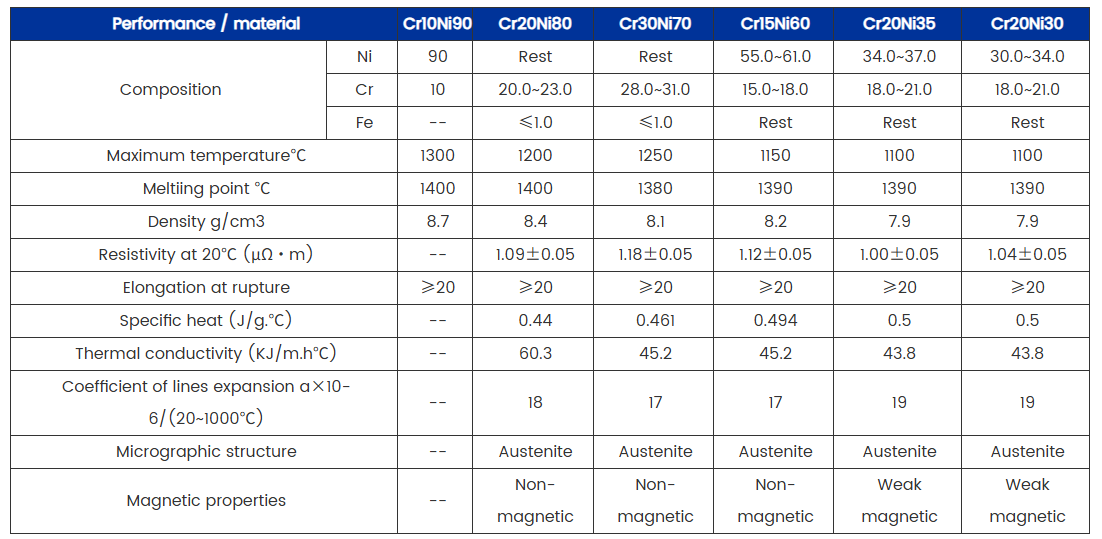

DLX Alloy Nichrome Wire is known for its excellent thermal conductivity of 15-20 W/mK, making it an ideal product for applications requiring high-temperature resistance. It is available in different grades, including Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr30Ni70, suitable for various industrial applications. The yield strength of the Nichrome Wire is 200-300 MPa, making it a strong and durable product.

The Nichrome Wire is available in the form of wire, making it easy to use for different applications. It is commonly used in the manufacturing of heating elements, such as in electric ovens, toasters, and hair dryers, among others. The product has a density of 8.4 G/cm3, making it a lightweight option for various applications.

DLX Alloy Nichrome Wire is suitable for different occasions and scenarios, such as in the medical industry, where it is used in Nitinol Pipe manufacturing. Nitinol is a nickel-titanium alloy that is commonly used in medical devices such as stents, orthodontic wires, and others. Nitinol has excellent shape memory and superelastic properties, making it an ideal material for these applications. DLX Alloy Nichrome Wire is also used in the aerospace industry, where it is used in the manufacture of aircraft engines and other high-temperature applications.

Customization:

Brand Name: DLX Alloy

Model Number: Nichrome Wire

Place of Origin: China JiangSu

Certification: CE

Minimum Order Quantity: 5

Packaging Details: Spool package with Carton box, Coil package with polybag for Resistance wire

Delivery Time: 5-21 days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 300 tons per month

Electrical Resistivity: 1.1-1.2 μΩm

Hardness: HV400-500

Grades: Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr30Ni70

Elongation: 20-30%

Applications: Heating Elements, Furnaces, Electrical Components

Support and Services:

Our Nichrome Alloy product comes with comprehensive technical support and services to ensure optimal performance and customer satisfaction. Our team of experts can provide assistance with product selection, installation, troubleshooting, and maintenance. We offer training programs to help customers understand the product and maximize its potential. Additionally, we provide regular updates and improvements to ensure that the product continues to meet the evolving needs of our customers. Our goal is to provide a seamless experience for our customers, from initial purchase to ongoing support and service.

Packing and Shipping:

Product Packaging:

The Nichrome Alloy product will be packed in a sturdy, cardboard box to ensure safe transportation.

The product will be securely wrapped in bubble wrap to prevent any damage during transit.

Shipping:

We offer worldwide shipping for the Nichrome Alloy product.

The product will be shipped via a reliable courier service to ensure timely delivery.

Shipping fees may vary depending on the destination.

The estimated delivery time will be provided at the time of checkout.

About Us:

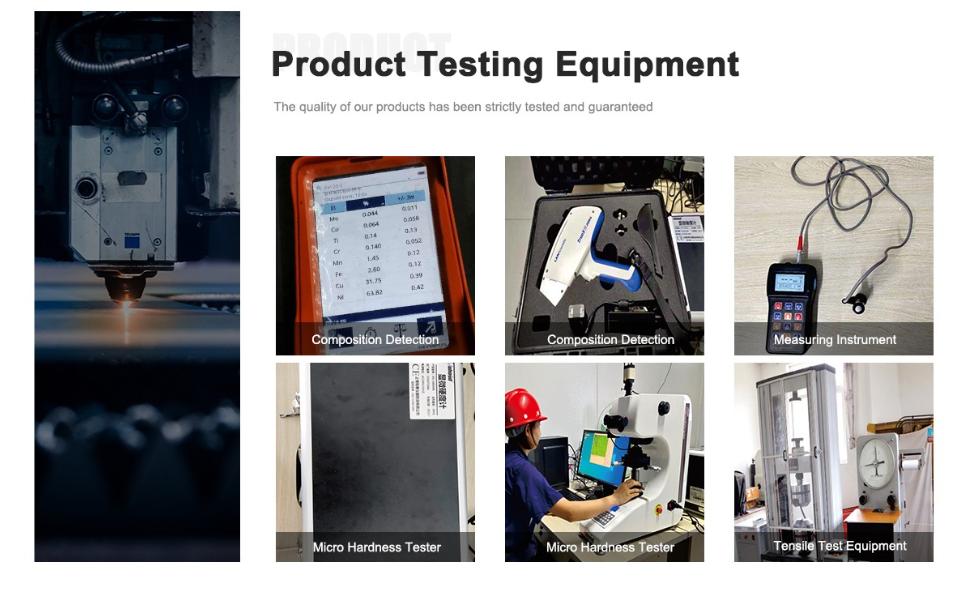

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why use Nichrome wire with 8.4 g/cm³ density for heating applications?

Its high density and corrosion resistance make it super reliable for heavy-duty heating systems.

How does this Nichrome wire’s melting point benefit industrial use?

The 1400-1450°C melting point ensures it can handle extreme heat without degrading.

Can this wire withstand corrosive environments?

Totally, its excellent corrosion resistance keeps it strong in harsh conditions.

How does this Nichrome compare to FeCrAl alloys?

Nichrome has better corrosion resistance, while FeCrAl can tolerate slightly higher temperatures.

Is this wire suitable for continuous high-heat applications?

Yup, it’s stable up to 1200°C, perfect for long-term industrial heating.

Is this Nichrome wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be shaped for custom heating elements?

Absolutely, its formability makes it great for tailored coil designs.

Is this wire cost-effective for high-temperature applications?

Yes, it balances top performance with reasonable cost for industrial needs.