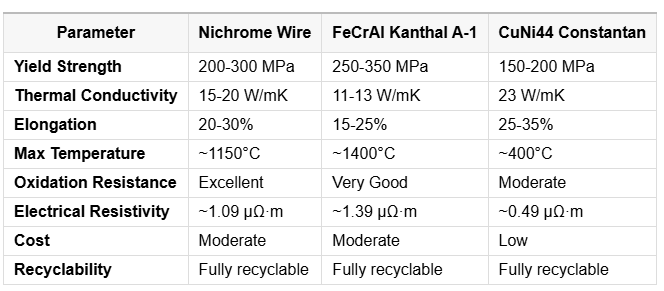

200-300 MPa Yield Strength Nichrome Wire 15-20 W/mK Thermal Conductivity 20-30% Elongation for Long

- Product Details

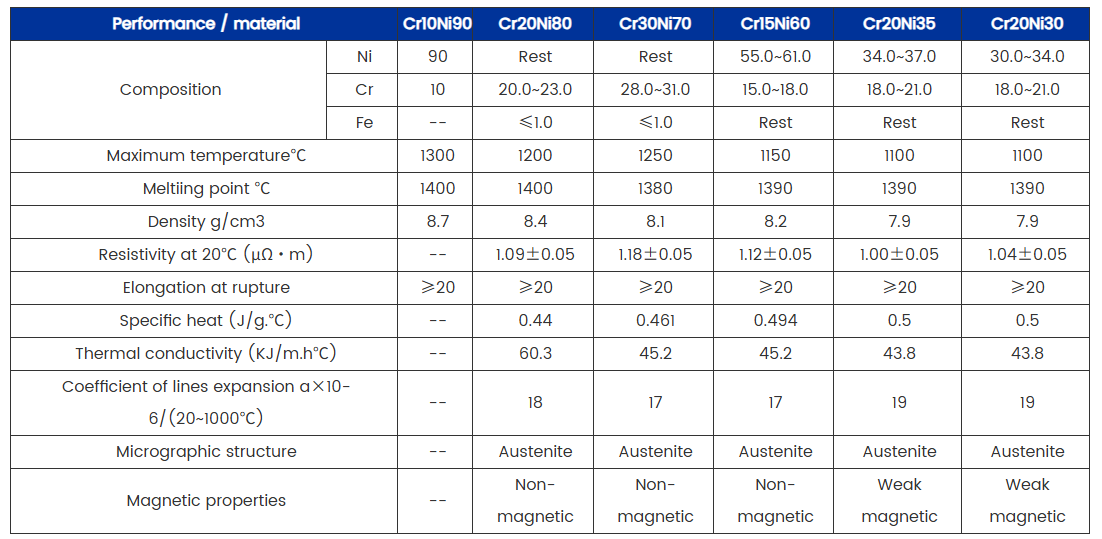

The Nichrome Alloy has a yield strength of 200-300 MPa, making it a robust and durable material. It has a density of 8.4 g/cm3, which is relatively light compared to other metals. The alloy has a melting point of 1400-1450°C, which is relatively high, making it suitable for high-temperature applications.

The Nichrome Alloy is a non-magnetic material, making it ideal for applications that require a non-magnetic environment. This property makes it ideal for use in the manufacture of medical devices such as Nitinol Pipe, which is used to create stents, catheters, and other medical devices. The non-magnetic property of the Nichrome Alloy ensures that it does not interfere with the magnetic resonance imaging (MRI) machines used in medical diagnosis.

Another essential property of the Nichrome Alloy is its excellent corrosion resistance. This property makes it ideal for use in harsh environments, such as those found in the aerospace and automotive industries. The alloy is resistant to both corrosion and oxidation, making it ideal for use in high-temperature environments.

In conclusion, the Nichrome Alloy is a versatile and high-performance material that offers excellent corrosion resistance and non-magnetic properties. It has a yield strength of 200-300 MPa, a density of 8.4 g/cm3, a melting point of 1400-1450°C, and is non-magnetic. These properties make it ideal for use in various industries, including medical devices, aerospace, and automotive. Its excellent corrosion resistance makes it an ideal material for use in harsh environments. Nichrome Alloy is the perfect material for the manufacture of Nitinol Pipe, which is widely used in the medical industry.

The DLX Alloy Nichrome Wire is a high-quality product that originates from China JiangSu and has CE certification. The minimum order quantity for this product is 5, and it comes in two packaging options: spool package with carton box or coil package with polybag for resistance wire. The delivery time for this product is between 5-21 days, and the payment terms include L/C, T/T, Western Union, and MoneyGram.

The DLX Alloy Nichrome Wire has a supply ability of 300 tons per month and a tensile strength of 400-500 MPa. Its chemical composition is Ni-Cr-Fe, and it has thermal conductivity of 15-20 W/mK. The product comes in four grades: Cr15Ni60, Cr20Ni35, Cr20Ni30, and Cr30Ni70.

The DLX Alloy Nichrome Wire is a versatile product with a range of applications. It is commonly used in heating elements, furnaces, and electrical components. Its high tensile strength and thermal conductivity make it a reliable choice for these applications.

The DLX Alloy Nichrome Wire is especially useful in the production of Nitinol Pipe. Nitinol is a nickel-titanium alloy that exhibits unique properties such as shape memory and superelasticity. The DLX Alloy Nichrome Wire is an essential component in the manufacture of Nitinol Pipe, which is widely used in the medical industry for applications such as stents and other implantable devices.

Overall, the DLX Alloy Nichrome Wire is a dependable product that offers a range of applications and benefits. Its high-quality composition and reliability make it an excellent choice for a variety of industries and scenarios.

Support and Services:

Nichrome Alloy is a high-resistance, nickel-chromium alloy that is commonly used in heating elements and other high-temperature applications. Our team of technical experts is available to provide support and services to ensure the optimal performance and longevity of your Nichrome Alloy products.

We offer:

Product selection guidance and consultation

Customized product design and engineering

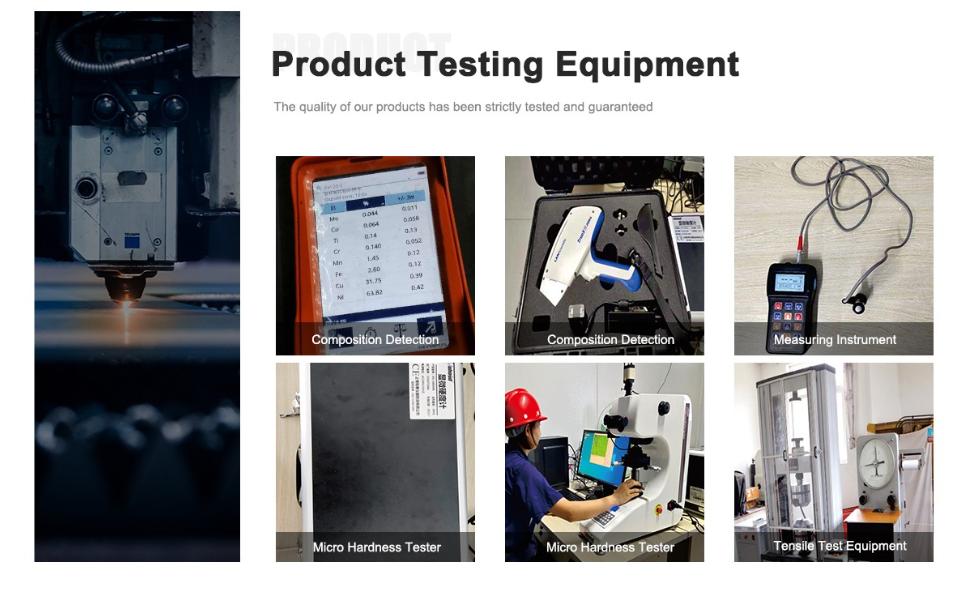

Material testing and analysis

Product installation and maintenance guidance

Troubleshooting and technical issue resolution

Our goal is to help you get the most out of your Nichrome Alloy products. Contact us for more information on our technical support and services.

Packing and Shipping:

Product Packaging:

Our Nichrome Alloy product is packaged in a sturdy and high-quality box to ensure safe delivery. The box is designed to protect the product from any damages during transportation. The product is also covered with a layer of protective material to prevent any scratches or other forms of damage.

Shipping:

We offer fast and reliable shipping options for our Nichrome Alloy product. Standard shipping usually takes 3-5 business days within the United States, while international shipping can take up to 2-3 weeks depending on the destination. Customers can also choose expedited shipping options for faster delivery.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why use this Nichrome wire for long-term heating applications?

Its high thermal conductivity and durability make it perfect for sustained, reliable heating.

What does 20-30% elongation mean for this wire?

It allows the wire to stretch and bend without breaking, ideal for complex designs.

How does 15-20 W/mK thermal conductivity benefit performance?

It ensures efficient heat transfer, great for consistent heating in ovens or furnaces.

Can this wire handle high temperatures?

Yup, it’s stable up to 1150°C, suitable for intense heating environments.

Is this Nichrome wire corrosion-resistant?

Totally, it forms a protective oxide layer to resist corrosion over time.

Is this wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

What applications suit its 200-300 MPa yield strength?

It’s perfect for applications needing moderate strength and high flexibility, like appliance heaters.

Is this Nichrome wire cost-effective for long-term use?

Yes, its durability and performance make it a budget-friendly choice over time.