Constant Wattage Heating Cables Process temperature maintenance

Release time:2025-03-09 Strike:173 Inquire Now

Constant Wattage Heating Cables Process temperature maintenance for sale

| Product Details | |

| Place Of Origin | China JiangSu |

Brand Name | DLX |

Model Number | Insulation Heating Cable |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Constant wattage heating cables are specifically designed for applications where maintaining a consistent process temperature is essential. Here’s how they work and their applications in process temperature maintenance:

Constant Wattage Heating Cables for Process Temperature Maintenance

How Constant Wattage Heating Cables Work

Consistent Heat Output:

Constant wattage heating cables provide a uniform heat output per unit length.

They maintain a constant power output regardless of variations in ambient temperature, ensuring predictable and reliable heating.

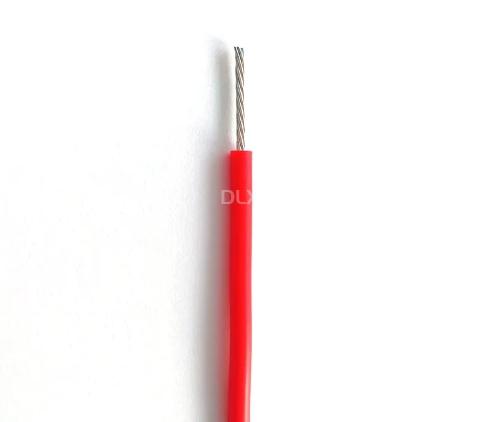

Construction:

Heating Element : Typically consists of a resistive heating wire or tape that generates heat when electrical current flows through it.

Insulation: Surrounds the heating element to minimize heat loss and ensure efficient heat transfer to the process equipment or pipeline.

Outer Jacket: Provides mechanical protection and weather resistance.

Installation:

Constant wattage heating cables are installed directly on the surface of process equipment, tanks, pipelines, or vessels that require heating.

They can be wrapped around the equipment or secured with clips and tape to ensure uniform heating coverage.

The cables are connected to a power source via appropriate junction boxes and temperature controllers for precise heat regulation.

Applications in Process Temperature Maintenance

Industrial Processes:

Chemical Processing: Used to heat reactors, vessels, and piping systems to maintain specific temperatures required for chemical reactions and processes.

Oil Refineries: Applied in distillation columns, storage tanks, and pipelines to prevent temperature fluctuations that could affect product quality and viscosity.

Food and Beverage Industry:

Breweries and Distilleries: Installed in fermentation tanks, mash tuns, and distillation columns to maintain optimal temperatures for brewing and distillation processes.

Food Processing Plants: Used to heat equipment and pipelines carrying food products such as chocolate, syrups, and sauces to ensure consistency and quality.

Pharmaceutical Manufacturing:

Utilized in pharmaceutical facilities to heat mixing vessels, reactors, and piping systems for the production of drugs and pharmaceutical products under controlled temperature conditions.

Water and Wastewater Treatment:

Applied in water treatment facilities to heat tanks, pipes, and digesters to maintain process temperatures required for effective treatment and digestion of wastewater.

Benefits of Constant Wattage Heating Cables for Process Temperature Maintenance

Reliable Heat Output: Provides consistent and predictable heat output, ensuring stable process temperatures.

Versatility: Suitable for a wide range of applications and industries where precise temperature control is critical.

Durability: Designed to withstand harsh environmental conditions, chemicals, and mechanical stress.

Energy Efficiency: Optimizes energy usage by delivering heat directly to the targeted area without overheating or wastage.

Summary

Constant wattage heating cables play a crucial role in maintaining process temperatures in various industrial applications. They offer reliable and uniform heat distribution, ensuring consistent product quality, operational efficiency, and regulatory compliance. Their versatility and durability make them a preferred choice for heating critical process equipment, pipelines, and tanks across industries such as chemical processing, food and beverage production, pharmaceuticals, and water treatment.

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

Q:How do you handle pre-sales and post-sales?

A:We have a professional business team that will work one-on-one with you to protect your product needs, and if you have any questions, he can answer them for you!

Q:Can I visit your factory before we place an order?

A:Yes, you are welcome to visit our factory. We are very pleased if we have the chance to know more about each other.

Q:Where can I find up-to-date information about the company?

A:You can check our news or blog for information about our company.

Q:Do the products meet quality standards?

A:All of our products meet quality standards. If you need a certificate for a specific country, we have a professional business team that will work with you one-on-one and can answer any questions you may have!

Q:Where are your production facilities located?

A:We manufacture our products in China and arrange for them to be shipped from China to your country as soon as possible, which usually depends on your product requirements and quantities.

230v 40w/m Constant Wattage Power Silicone Insulation Heating Cable For Pipe Tracing

230v 40w/m Constant Wattage Power Silicone Insulation Heating Ca...

Insulation Heating Cable heating cable for pipe tracing

Insulation Heating Cable heating cable for pipe tracing for sale...

Heating Cable Insulation Heating Cable

Heating Cable Insulation Heating Cable for sale...

Constant Wattage Heating Cable Insulated Heating Tapes for holding pipes

Constant Wattage Heating Cable Insulated Heating Tapes for holdi...