Roles of common elements in electric Resistance wires

Release time:2025-03-09 Strike:196 Inquire Now

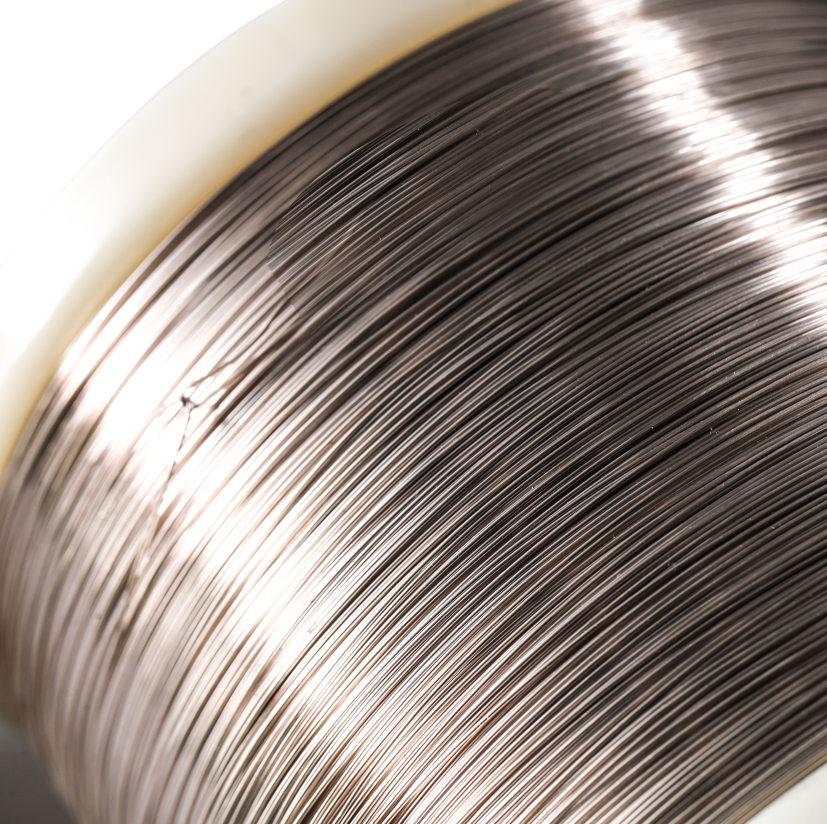

Electric heating wires are common resistive heating materials that utilize the electrical resistance properties of metal elements for heat generation.

In order to enhance the performance of these wires and achieve specific characteristics, various elemental components are intentionally added during the smelting process,

hence they are often referred to as electric heating alloys.

The commonly used materials for heating wires can mainly be divided into two categories: Ni-Cr and Fe-Cr-Al alloys.

They are widely employed in industrial furnaces, laboratory heaters, and household appliances as heating elements.

1. The Ni-Cr series heating wires are based on nickel (or iron), generally containing 15% to 30% chromium and 29% to 80% nickel. They exhibit an austenitic structure.

The commonly used Cr20Ni80 heating wire has a maximum operating temperature of 1200°C.

2. The Fe-Cr-Al series resistance ribbons are based on iron, typically containing 12% to 30% chromium, 4% to 8% aluminum, with iron as the balance.

They have a ferritic structure and can withstand temperatures up to 1400°C.

Roles of common elements in electric heating wires:

- Chromium: Enhances oxidation resistance, high-temperature oxidation resistance, and sulfidation resistance, and improves resistance to pitting and crevice corrosion.

- Nickel: Provides metallurgical stability, improves thermal stability and weldability, enhances resistance to reducing acids and caustic soda,

particularly improves stress corrosion cracking resistance in chloride and caustic soda environments.

- Iron: Increases resistance to high-temperature carburizing environments, reduces alloy costs, and controls thermal expansion.

- Aluminum: Improves high-temperature oxidation resistance and age-hardening properties.

- Niobium: Combines with carbon to reduce intergranular corrosion caused by chromium carbide precipitation during heat treatment, improves resistance to pitting and crevice corrosion.

- Molybdenum: Enhances resistance to reducing acids, improves resistance to pitting and crevice corrosion in chloride solution environments, and increases high-temperature strength.

- Cobalt: Provides enhanced high-temperature strength, improves resistance to carburization and sulfidation.

- Copper: Enhances resistance ribbons' resistance to reducing acids (especially those used in non-ventilated environments such as sulfuric acid and hydrofluoric acid) and salts.

Addition of copper to nickel-chromium-molybdenum-iron alloys helps improve resistance to hydrofluoric acid, phosphoric acid, and sulfuric acid.

- Titanium: Combines with carbon to reduce intergranular corrosion caused by chromium carbide precipitation during heat treatment,

enhances age-hardening properties of resistance ribbons, and improves high-temperature strength.

- Tungsten: Improves performance against reducing acids and localized corrosion, enhances strength and weldability of resistance ribbons.

- Nitrogen: Enhances metallurgical stability, improves resistance to pitting and crevice corrosion, and increases strength.

These elements play crucial roles in enhancing the performance and durability of electric heating wires in various operational environments.

However, in the PMI test, the rare materials are unable to be shown in the list. How to make sure the material meets the standard (GB/T1234-2012) is a problem.

But I think choosing a reliable team and trusted worthy people is always the most important to ensure your investment is safe and worthwhile. DLX Alloy team has over 20 years experience,

we served over 2000 customers around the world. Our mission is to pass the confidence of Made In China to all of our valued customers. Feel free to contact us for more!

How does the air fryer get heated?

An air fryer gets heated using an electric heating element combi...

How does a Kettle heat water?

A kettle typically uses a metal coil heating element to heat wat...

How is resistance wire used in a hair dryer?

A resistance wire in a hair dryer is used as the heating element...

BIS Certificate Required for Non-ferrous Materials Importing

In India, the regulation of non-ferrous materials, such as alumi...