At DLX ALLOY Company, we have produced different surfaces of FeCrAl wires to satisfy our valued customers' various needs.

For thick wires or coils, the NO.1 ordered is a Sour White surface. Our valued Indian customers usually order this type by container, such as SWG14 0Cr21Al4/0Cr21Al6/0Cr23Al5 with a Sour white surface.

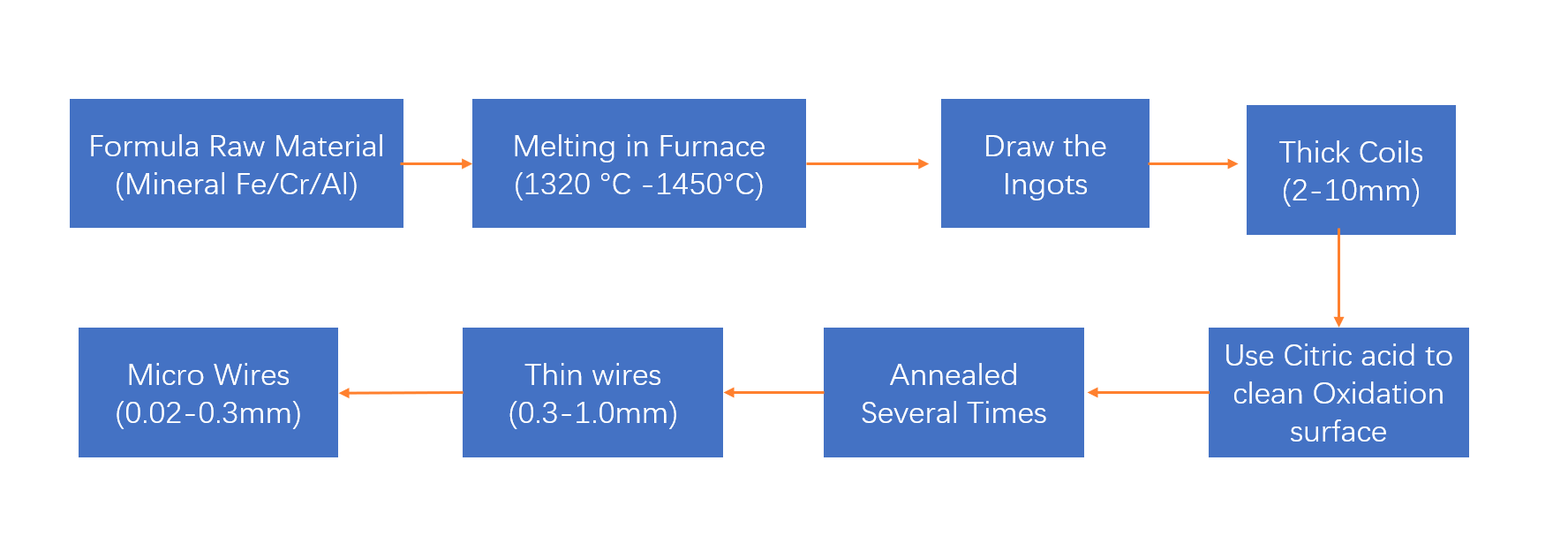

Well if to explain the surface treatment of resistance wire, an understanding of the FeCrAl production process is necessary.

FeCrAl Resistance wire production process. If you hate the long passage, you may jump to the sketch directly.

(1) Raw material selection: powdered iron, chromium, aluminum, rhenium, copper, etc. are selected as processing raw materials;

(2) Heating and smelting: select a quartz crucible, first add the raw materials and stir them evenly, then put them into an induction furnace for heating and smelting to obtain a metal solution, the heating temperature is 1320℃-1450℃;

(3) Cooling and forming: the metal solution is cooled to form a metal material;

(4) Resistance wire drawing: at room temperature, the metal material is used to draw the resistance wire using a wire drawing machine;

(5) Single wire annealing: the resistance wire is heated to a certain temperature to recrystallize;

(6) Surface treatment: pre-treat the surface of the resistance wire;

(7) Twisting: twist multiple single wires of the resistance wire together.

Preferably, in the step (4), the single wire annealing temperature is controlled at 350-450℃, and the annealing time is 20-30min.

Preferably, in step (1), the proportion of iron in the raw material is 65.9%-70.6%, the proportion of chromium is 12.5%-15.0%, the proportion of aluminum is 14.6%-16.0%, the proportion of rhenium is 0.5%-0.8%, and the balance is copper.

Preferably, in step (6), the resistance wire is treated with 5%-15% (mass fraction) of ammonium citrate at 60°C for 30 minutes, then washed with cold water, placed in an alkaline permanganate bath for 15 minutes, and then washed with cold water for 2 minutes.

Here I made a simple sketch to show the process

Now we can answer the question about the surface color. In the process of Acid washing, we get the sour white surface

Before the acid washing, it is the black Oxidized Surface

After several times of annealing and drawing, the wires own the Bright Surface

If we add some special elements in the annealing process,we could get Golden or Blue color wires

Want to know more about the Heating Resistance wire production details? Please leave a message, our engineers will contact you ASAP.