Alloy52 Nickel Iron Application:PrecisionSemiconductor Packaging

Release time:2025-03-09 Strike:107 Inquire Now

Real-world applications of Alloy52

specifically focusing on how its properties make it suitable for various temperature-dependent environments.

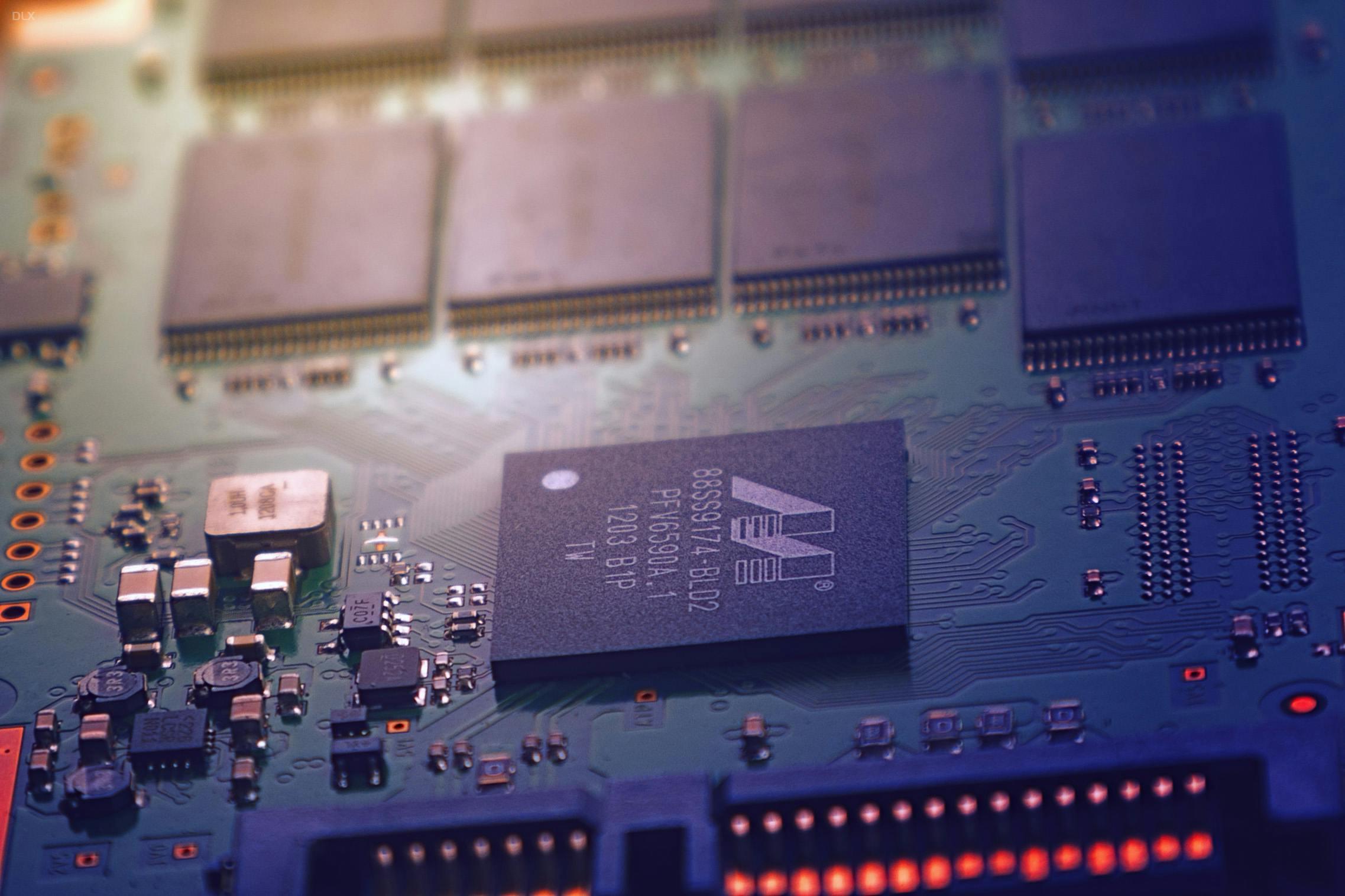

1. Precision Electronics and Semiconductor Packaging

Application: Alloy52 is often used in electronic packaging, particularly in semiconductor devices, due to its low thermal expansion properties. This ensures that components within a semiconductor package don't experience thermal stress when heating or cooling during operation, which can damage the delicate circuitry.

Why it works: The low CTE (Coefficient of Thermal Expansion) of Alloy52 (around 5.3 × 10⁻⁶ /°C) makes it a perfect match with silicon, whose CTE is very similar (around 2.5 × 10⁻⁶ /°C). This compatibility minimizes the risk of thermal mismatch, which could cause cracks or delamination of the chip during temperature fluctuations.

Temperature Range: Typically used in applications with a temperature range of -50°C to 200°C, though this can extend to 400°C depending on the specific application.

Example: Leadframe materials in integrated circuits or chip-on-board (COB) packaging.

2. Glass Sealing

Application: Alloy52 is widely used in glass-to-metal seals, which are critical for hermetic sealing in electronic devices, automotive, aerospace, and military applications.

Why it works: In these seals, the goal is to match the thermal expansion properties of the glass and metal components. Since Alloy52 has a low CTE, it can expand and contract at a similar rate to the glass, creating a reliable, tight seal. This prevents air or moisture from entering sensitive electronic components or devices, which is critical for the longevity and reliability of these systems.

Temperature Range: Alloy52 is typically used for glass seals that must perform in environments between -50°C to 250°C.

Example: Sealing of vacuum tubes, electronic device hermetic packaging, and automotive lighting.

3. Aerospace Applications

Application: Alloy52 is utilized in the aerospace industry, especially in thermally stressed components, such as parts that experience rapid temperature changes or need to withstand high altitudes (where extreme temperature variations occur).

Why it works: The alloy’s low expansion is useful in components where thermal cycling occurs—like electronic connections in aircraft, spacecraft, or satellites. Alloy52 maintains its dimensional stability despite fluctuating temperatures, ensuring that the materials continue to perform consistently under high stress.

Temperature Range: Components may experience temperatures ranging from -50°C to 300°C, depending on altitude and exposure to space or the upper atmosphere.

Example: Wiring systems, aerospace sensor housings, and electronic control modules.

4. Vacuum and High-Temperature Systems

Application: Alloy52 is sometimes used in vacuum systems and high-temperature equipment that require stable, low-expansion materials. Examples include applications in high-performance vacuum pumps and metal sealing in ultra-high vacuum (UHV) environments.

Why it works: In vacuum systems, materials must maintain integrity under both extreme temperature gradients and low-pressure conditions. Alloy52’s low thermal expansion and good strength at elevated temperatures make it suitable for components like flanges, seals, and structural parts in high-vacuum equipment.

Temperature Range: The alloy can handle temperatures ranging from -50°C to 400°C, but more commonly it is used in systems operating at temperatures up to 250°C-300°C.

Example: UHV chambers, vacuum furnaces, and high-temperature reactors.

5. Automotive Electronics and Sensors

Application: In the automotive industry, Alloy52 is used for electronic sensors, temperature control units, and engine control systems. Modern vehicles rely on electronics that must function reliably in high-temperature environments.

Why it works: The alloy's low expansion properties ensure that electrical connections remain intact even when the engine compartment or external sensors are exposed to extreme temperature changes, from cold winters to hot summers.

Temperature Range: Automotive applications often deal with temperatures ranging from -40°C to 150°C, though extreme conditions may push up to 200°C.

Example: Oxygen sensors, engine control units (ECUs), and temperature probes in exhaust systems.

6. Thermocouples and Temperature Sensors

Application: Thermocouples made from Nickel-Iron alloys like Alloy52 are used for temperature measurement in high-precision environments, such as furnaces, chemical reactors, or industrial ovens.

Why it works: The material’s low expansion and stable electrical properties under varying temperatures allow it to maintain accuracy in temperature readings over a wide range.

Temperature Range: These thermocouples can measure temperatures from -200°C to 1300°C, though Alloy52 would typically be used in the lower to mid-range of this spectrum.

Example: High-temperature thermocouples in industrial process control or temperature sensors in aerospace engines.

7. Cryogenic Applications

Application: Alloy52 is also employed in certain cryogenic applications, such as cryogenic tanks and liquid gas systems.

Why it works: The low CTE is beneficial in ensuring that the material maintains its structural integrity when exposed to extremely low temperatures (like liquid nitrogen or liquid helium). This prevents cracking or failure when the material contracts at very low temperatures.

Temperature Range: Alloy52 can operate in environments as low as -196°C (liquid nitrogen) and can handle cryogenic temperatures up to -253°C (liquid helium).

Example: Cryogenic tank seals, cold storage containers, and fuel lines in space missions.

8. Nuclear Applications

Application: Alloy52 is sometimes used in nuclear reactors for specific applications, particularly in control rods or structural components.

Why it works: The material’s high strength at elevated temperatures and dimensional stability makes it useful in environments where temperature changes are extreme, and where material integrity is critical.

Temperature Range: Operating temperatures in reactors can reach 500°C or higher, though the alloy's usage would depend on specific reactor conditions.

Example: Nuclear reactor control rods or stainless steel clad components.

Summary

In essence, Alloy52 is well-suited for applications where both dimensional stability and high-temperature performance are required. Its low thermal expansion makes it ideal for precision electronics, sealing, aerospace, and high-temperature industrial applications. However, its strength reduction at high temperatures limits its use in very high-stress environments above 400°C.

Each of these applications takes advantage of Alloy52's key characteristics, such as low thermal expansion, good high-temperature strength, and resilience under thermal cycling, making it a versatile material for high-precision and temperature-sensitive environments.

How does the air fryer get heated?

An air fryer gets heated using an electric heating element combi...

How does a Kettle heat water?

A kettle typically uses a metal coil heating element to heat wat...

How is resistance wire used in a hair dryer?

A resistance wire in a hair dryer is used as the heating element...

BIS Certificate Required for Non-ferrous Materials Importing

In India, the regulation of non-ferrous materials, such as alumi...