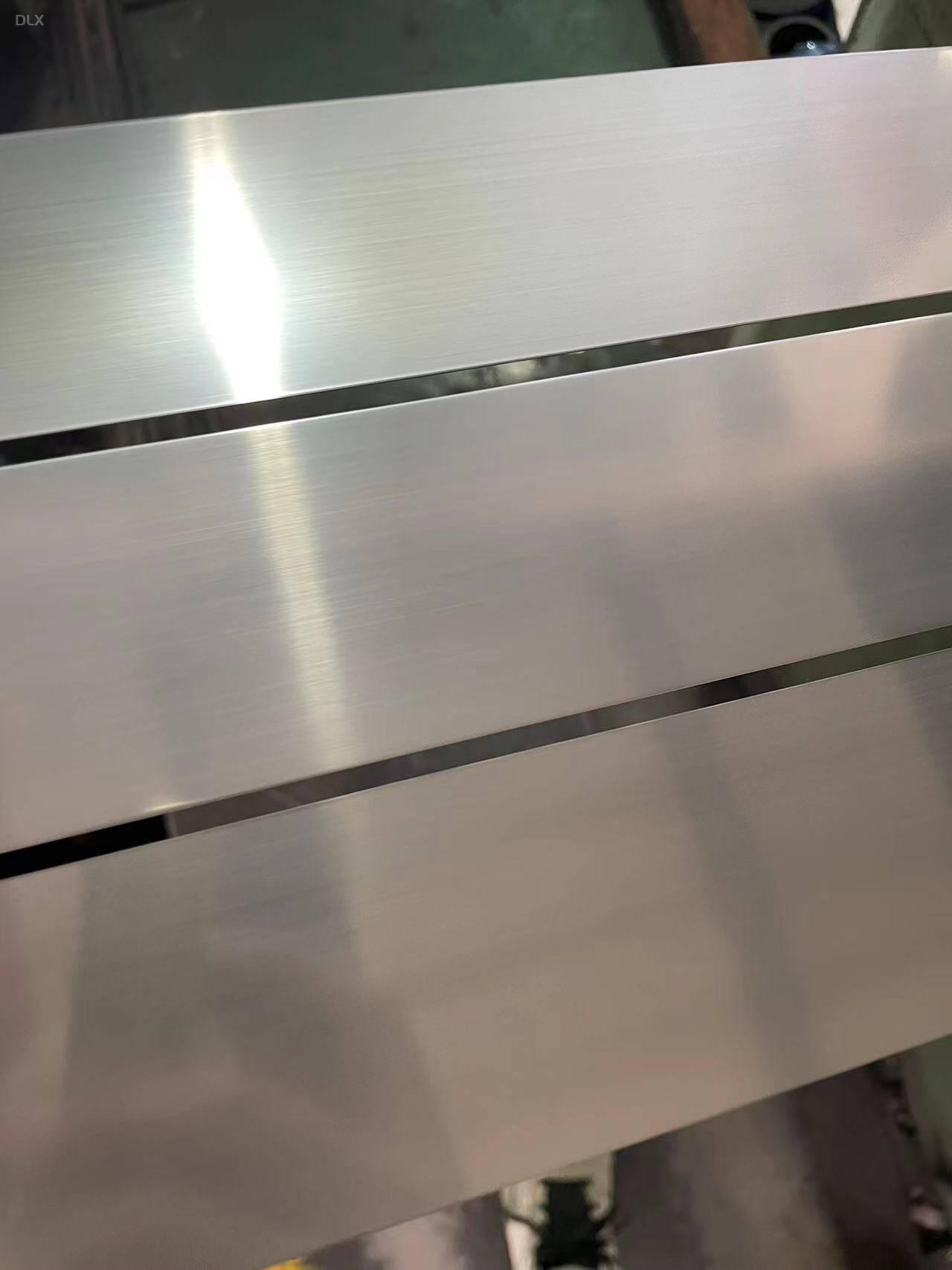

0.025mm and 0.04mm Invar36 strip Applied in OLED

Release time:2025-03-09 Strike:102 Inquire Now

FMM is a key and essential consumable mold for the OLED production process of panel factories.

FMM stands for Fine Metal Mask, which is a key mold required by all factories producing OLED panels. The OLED panel process is roughly composed of several sections such as backplane, evaporation, and module. The quality of FMM directly affects the yield of the evaporation section and the quality of product display. In particular, the production of ultra-high precision (High PPI) OLED panels has high requirements for FMM raw materials and manufacturing processes.

FMM belongs to a key subdivided material end market, which has been in an oligopolistic situation for a long time and has a strong entry barrier. Globally, the only FMM supplier that can produce ultra-high specification OLED panels is DNP in Japan. Xu Huawei, CEO ofDLX ALLOY, told 36Kr that the global FMM demand in 2023 will be about 450,000, and more than 95% will be supplied by DNP in Japan. Under the background of limited globalization, the risk of the industrial chain is huge.

Due to commercial reasons, DNP has a quality gap in the supply of products to different customers. The FMM specifications supplied to domestic panel factories are lower than those supplied to Samsung. Most domestic panel factories cannot get first-class FMM supply and the delivery time is long, which greatly affects the factory yield and limits the ability of domestic panel factories to manufacture high-end ultra-fine OLED panels. Based on this advantage, Samsung has been able to slow down the momentum of domestic OLED panel factories to catch up, giving itself more time to find new opportunities.

At present, China accounts for more than half of the global trillion-dollar OLED panel investment. As the competition for OLED panel supply intensifies, the market share of domestic panel factories has gradually expanded, but due to DNP's differentiated quality supply strategy, the panel quality of domestic panel factories has always been behind Samsung.

It can be said that the supply of FMM has become an important part of the competition between China and South Korea for OLED technology.

In addition to DNP, there are many companies in China, South Korea and Taiwan that invest in FMM, but they have never changed the pattern of DNP's monopoly on the market, mainly because there is no solution for Invar36 alloy.

There are three core bottlenecks in FMM manufacturing: first, the industry monopoly threshold is extremely high; second, the quality inspection of the core raw material Invar36 alloy (iron-nickel alloy with a specific ratio) thin strip is difficult; third, the production and manufacturing process of FMM is extremely easy to be discrete.

DNP has been the only one for many years. In addition to having a better production control process, the monopoly of the core raw material Invar36 alloy is the most critical reason.

The upstream core raw material Invar36 alloy (iron-nickel alloy) foil of FMM mainly comes from Hitachi Metals of Japan. The company has signed an exclusive supply agreement with DNP for mainstream products, forming a monopoly in the industrial chain.

Therefore, Xu Huawei decided to lead the team to solve this pain point, starting from the downstream to the upstream, and completely changing the situation.

Breaking the myth of irreplaceability

To completely solve the problem of mass production of domestically produced FMM, and then solve the situation that the OLED industry is controlled by people, it is necessary to completely solve the development and mass production supply of the upstream core Invar36 alloy raw materials.

After figuring out the question of "which came first, the chicken or the egg", in 2020,DLX ALLOY began to develop Invar36 alloy raw materials.

Since the precision and quality requirements of Invar36 alloy are much higher than the processing standards of the traditional metal industry, and the market is too segmented, the material development cycle is long and the development cost is high. General steel companies rarely have the willingness and ability to enter the development.

Invar36 alloy is used in high-precision FMM production, and its core quality requirements include ultra-high material purity (low inclusion content), good control of thin strip shape and surface defects, etc.

Hitachi Metals' Invar36 alloy thin strip is far superior to other suppliers in the market in terms of purity and shape control. This is related to the development advantages caused by the extreme segmentation of the Japanese market, which has also created DNP's monopoly on FMM for decades.

Xu Huawei believes that the biggest pain point of domestic clients is that "DNP has supply discrimination against customers, which also makes it difficult for customers to meet their high-end product needs."

Therefore, starting from the client, the company decided to take the "high-profile route" from the beginning and compete head-on with DNP's mainstream products. From the beginning of taking samples to develop the first customer, Xu Huawei's team showed the sincerity of fully covering the bottom for customers. After all, once customers try to cooperate with other companies, they will be threatened with supply cuts under the DNP exclusive agreement. In this situation,DLX ALLOY completed the industry's mainstream G6 products in just one and a half years, corresponding to the comprehensive verification and delivery of watches, mobile phones, folding, tablets, laptops, and car screen products, which is the first in the industry.

From the product point of view,DLX ALLOY has completely opened up the industry's long-standing process black box in 2023 through a large number of technical tests and comprehensive over-specification customization of equipment processes in 2021, as well as process research and development of Invar36 alloy raw materials and OLED evaporation on the product design side in 2022. The technical chain of "Invar36 alloy materials-FMM production-evaporation application-terminal display" is connected for the first time, truly linking the specifications of FMM products with terminal displays, greatly reducing the ineffective losses of the industry's industrial chain.

Xu Huawei told 36Kr that the products ofDLX ALLOY have been applied to the mid-to-high-end flagship products of various terminal brands, covering watches, mobile phones, folding, tablets, and car-mounted products. The quality is the first in all customer reputations, and it has the only domestic and the only two in the world to supply medium and large-sized products. The mainstream production lines of major domestic customers have basically achieved full coverage, becoming the de facto domestic FMM leader.

From the material side, in the short term,DLX ALLOY extends to upstream alloy materials through understanding the downstream customer process, and conducts special screening, interception, and post-modification treatment to greatly improve the quality of Invar36 alloy thin strips put into production lines, so that it can meet the quality requirements of customers. In the medium and long term,DLX ALLOY has developed the smelting, forging, and cold rolling processes of Invar36 alloy from the source, completing the development and quality improvement of the entire industrial chain to meet the needs of FMM use.

At present, according to Xu Huawei, after nearly four years of development,DLX ALLOY has completed the development of Invar36 alloy from smelting to cold-rolled thin strips, and has been promoted to mass production. In December 2023, the first batch of FMM produced with domestically produced Invar36 ribbons has been sent to key domestic customers, and passed the initial mass production verification of the client in April this year. It is expected that the replacement rate of domestically produced Invar36 alloy ribbons will reach more than 10% by the end of the year.

In terms of quality, by the end of 2023, the 40um pure domestic Invar36 alloy ribbon has exceeded the level of existing imported materials, and after later modification, it is close to the level of Japan's Hitachi Metals, and some core indicators have exceeded Hitachi Metals (such as the content of metal inclusions). By the end of 2024, the development and mass production of Invar36 alloy ribbons after 25um will be completed (Hitachi Metals mainly mass-produces alloy ribbon categories).

So far,DLX ALLOY has broken the blockade restrictions of Japan's DNP, Hitachi Metals, and South Korea's Samsung in terms of materials and product quality, and has achieved a complete breakthrough in the "0" of domestically produced FMM in the domestic OLED display industry, and has begun to enter the "1-100" stage.

BeforeDLX ALLOY, many companies entered this market segment. Xu Huawei recalled that as early as 2013, Chinese, Korean and Japanese companies entered the market, but due to insufficient market demand, wrong technology route selection, and lack of breakthroughs in key materials, by 2018, "almost all of them died."

The emergence of DLX ALLOY hit the right time point and found an outlet for its technology. Today, DNP's global monopoly has been broken. Not only has the risk of a single supplier for domestic panel manufacturers been greatly reduced, but Samsung's strategy of using DNP to restrict Chinese OLED companies from catching up with Samsung has also been shattered. In the future, the domestic OLED market may rise again.

How does the air fryer get heated?

An air fryer gets heated using an electric heating element combi...

How does a Kettle heat water?

A kettle typically uses a metal coil heating element to heat wat...

How is resistance wire used in a hair dryer?

A resistance wire in a hair dryer is used as the heating element...

BIS Certificate Required for Non-ferrous Materials Importing

In India, the regulation of non-ferrous materials, such as alumi...