Kiln Heating element-Surface Area Loading

Release time:2025-03-09 Strike:184 Inquire Now

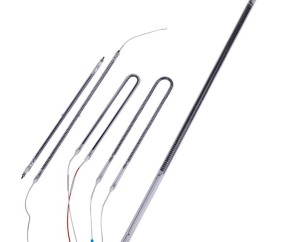

How to Calculate the Surface Area Loading of Kiln Heating Element

The term "surface load" is used to mean a quotient of power and surface. The surface load is mostly specified in 'W/Cm². The selection of the surface load is a function of the type of heating element on the one hand and the function of the type of the fluid on the other hand. The worse the fluid can dissipate the heat from the surface of the heater or the more thermally sensitive the fluid is, the lower must the surface load be selected.

While the transferable quantity of heat is limited by the medium in traditional heat exchangers, the dissipated quantity of heat is constant in case of electrical heating elements. The consumed electrical power is almost completely transferred to the fluid. If the heat transfer is hindered (i.e. the surface load is too high for this case), the fluid (and the heating element) will overheat.

It is possible to design a heating element in a variety of sizes all of which would in theory give the desired wattage load or power density dissipated per unit area. However, the load on the surface of the heating element mustn't be too high as the transfer of heat by conduction, convection or radiation from the element may not be rapid enough to prevent it overheating and failing prematurely.

The suggested surface loading range for the type of appliance and heating element are shown below – but this may need to be lower for a heating element working with more frequent operating cycles, or at nearly its maximum operating temperature, or in harsh atmospheres.

| Appliance | Element Type | Suggested Surface Loading Range (W/cm²) |

|---|---|---|

| Fire | Spiral Element in Free Air | 4.5 – 6.0 |

| Fire | Pencil Bar | 6.0 – 9.5 |

| Band Heater | Mica-Wound Element | 4.0 – 5.5 |

| Toaster | Mica-Wound Element | 3.0 – 4.0 |

| Convector | Spiral Element | 3.5 – 4.5 |

| Storage Heater | Spiral Element | 1.5 – 2.5 |

| Fan Heater | Spiral Element | 9.0 – 15.0 |

| Oven Element | Tubular Sheathed Element | 8.0 – 12.0 |

| Kiln Element | 15.0 – 20.0 | |

| Hotplate | 17.0 – 22.0 | |

| Water Immersion Heater | 25.0 – 35.0 | |

| Kettle Element | 35.0 – 50.0 |

To verify the surface area loading (S):

S = W / (l x d x 31.416)

W = Power (Watts)

S = Surface Area Loading (W/cm²)

I = Wire Length (m)

d = Wire diameter (mm)

This surface area loading should fall within the range shown in the table above for heating element type noting that a higher value gives a hotter element. The surface area loading can be higher or lower if it is considered the heat transfer be better or worse, or depending upon the importance of the heating elements life.

If your calculated surface area loading is too high or low you should re-calculate changing one or more of the following:

The wire length and diameter

The grade of the heating element alloy

How does a heating tube work in a Oven?

A heating tube in an oven works by converting electrical energy...

Why is Tungsten Used as a Welding Tip?

Why is Tungsten Used as a Welding Tip?Tungsten is used as the we...

What is Halogen Heating Tube

Halogen Heating Tube: An OverviewA halogen heating tube is an ad...

Carbon fiber heating Tube

What is a Carbon fiber heating Tube?Carbon Fiber Heating Tubes a...