Infrared (IR) Heating Elements Strip Used in drying paints, coatings, and textiles

Release time:2025-03-09 Strike:164 Inquire Now

Infrared (IR) Heating Element s Strip Used in drying paints, coatings, and textiles for sale

| Product Details | |

| Place Of Origin | China JiangSu |

Brand Name | DLX |

Model Number | Heating Element |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

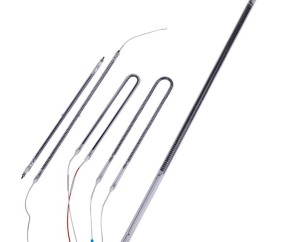

Infrared (IR) heating elements are highly effective for drying paints, coatings, and textiles due to their ability to transfer heat directly to the materials being processed. Here’s how IR heating elements work and their applications in these industries:

Infrared (IR) Heating Elements Strips for Drying Processes

How IR Heating Elements Work

Radiant Heat Transfer:

IR heating elements emit infrared radiation, which directly heats the surface of paints, coatings, or textiles without heating the surrounding air.

This efficient heat transfer method accelerates drying by quickly evaporating moisture and solvents from the surface of the material.

Types of IR Heating Elements:

Quartz Tubes: These elements emit medium to long-wave infrared radiation and are versatile for various drying applications.

Ceramic Elements: Known for their durability and ability to emit consistent heat, ceramic IR elements are used in industrial drying processes.

Carbon Fiber Elements: Offer rapid heating and cooling cycles, making them suitable for precise temperature control in drying applications.

Applications in Drying Processes

Paint and Coatings Industry:

IR heating elements are used to dry automotive paints, industrial coatings, and architectural finishes.

They provide uniform heating across surfaces, reducing drying times and improving production efficiency.

Textile Industry:

In textile manufacturing, IR heating elements dry fabrics, dyed yarns, and printed textiles quickly and evenly.

They are used in drying chambers or integrated into textile processing lines for continuous production.

Printing and Packaging:

IR heaters facilitate rapid drying of inks, adhesives, and coatings on printed materials and packaging substrates.

They ensure fast curing times and enhance print quality by preventing smudging or bleeding.

Benefits of IR Heating Elements

Energy Efficiency: Direct heat transfer reduces energy consumption compared to conventional drying methods that heat the air.

Fast Drying Times: IR radiation quickly heats the surface of materials, reducing overall processing times and increasing throughput.

Controlled Heating: Precise temperature control allows for consistent drying results without overheating or damaging sensitive materials.

Space Efficiency: Compact designs and flexible installation options make IR heaters suitable for various production environments.

Summary

IR heating elements play a crucial role in drying processes across industries such as paint and coatings, textiles, and printing. Their ability to provide rapid and uniform heat transfer improves efficiency, reduces energy costs, and enhances product quality. By directly heating surfaces without warming the surrounding air, IR heating elements offer precise control over drying times and temperatures, making them ideal for applications requiring fast and effective drying of paints, coatings, and textiles.

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

Q:How do you handle pre-sales and post-sales?

A:We have a professional business team that will work one-on-one with you to protect your product needs, and if you have any questions, he can answer them for you!

Q:Can I visit your factory before we place an order?

A:Yes, you are welcome to visit our factory. We are very pleased if we have the chance to know more about each other.

Q:Where can I find up-to-date information about the company?

A:You can check our news or blog for information about our company.

Q:Do the products meet quality standards?

A:All of our products meet quality standards. If you need a certificate for a specific country, we have a professional business team that will work with you one-on-one and can answer any questions you may have!

Q:Where are your production facilities located?

A:We manufacture our products in China and arrange for them to be shipped from China to your country as soon as possible, which usually depends on your product requirements and quantities.

How does a heating tube work in a Oven?

A heating tube in an oven works by converting electrical energy...

Why is Tungsten Used as a Welding Tip?

Why is Tungsten Used as a Welding Tip?Tungsten is used as the we...

What is Halogen Heating Tube

Halogen Heating Tube: An OverviewA halogen heating tube is an ad...

Carbon fiber heating Tube

What is a Carbon fiber heating Tube?Carbon Fiber Heating Tubes a...