Why is Tungsten Used as a Welding Tip?

- Product Details

Why is Tungsten Used as a Welding Tip?

Tungsten is used as the welding tip (electrode) in TIG (Tungsten Inert Gas) welding, also known as GTAW (Gas Tungsten Arc Welding), because of its unique physical and chemical properties that allow it to withstand extreme conditions during welding.

Key Reasons for Using Tungsten in Welding Tips

1️⃣ Extremely High Melting Point

Tungsten has the highest melting point of any metal: 3,422°C (6,192°F).

This allows it to endure high welding temperatures without melting or deforming.

2️⃣ Excellent Electrical Conductivity

Ensures a stable arc and efficient heat transfer, leading to precise and controlled welding.

3️⃣ High Hardness & Wear Resistance

Resists erosion and contamination from molten metal, extending its lifespan.

4️⃣ Minimal Contamination

Tungsten electrodes do not burn off easily, preventing contamination of the weld.

Other metals may melt or deposit impurities into the weld, affecting its quality.

5️⃣ Stable Arc Performance

Produces a consistent and stable welding arc, essential for high-quality welds.

Helps achieve precise control over heat input and weld penetration.

6️⃣ Chemical Stability

Tungsten is highly resistant to oxidation and corrosion, making it ideal for welding in inert gas environments (Argon, Helium).

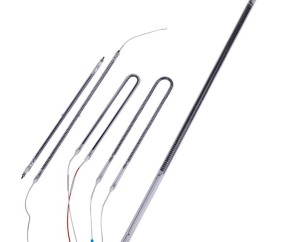

Types of Tungsten Electrodes Used in Welding

Tungsten electrodes come in different compositions to suit various welding applications:

| Electrode Type | Composition | Key Features | Common Use |

|---|---|---|---|

| Pure Tungsten (Green, WP) | 99.5% Tungsten | Good arc stability, low current capacity | Aluminum, Magnesium (AC welding) |

| Thoriated Tungsten (Red, WT-2%) | 97.5% W, 2% Thoria | Best arc stability, long lifespan | Steel, Stainless Steel (DC welding) |

| Ceriated Tungsten (Grey, WC-2%) | 98% W, 2% Ceria | Lower amperage, good arc control | Thin metals, delicate welding |

| Lanthanated Tungsten (Blue, WL-2%) | 98% W, 2% Lanthana | Excellent arc start, multipurpose | Both AC & DC welding |

| Zirconiated Tungsten (White, WZr-1%) | 99% W, 1% Zirconia | Best for high-amperage AC welding | Aluminum, Magnesium |

Conclusion

Tungsten is the best material for welding tips due to its high melting point, durability, electrical conductivity, and arc stability. This makes it essential for precision welding applications, such as in aerospace, automotive, and industrial fabrication.

Would you like recommendations on choosing the right tungsten electrode for a specific welding application? 😊