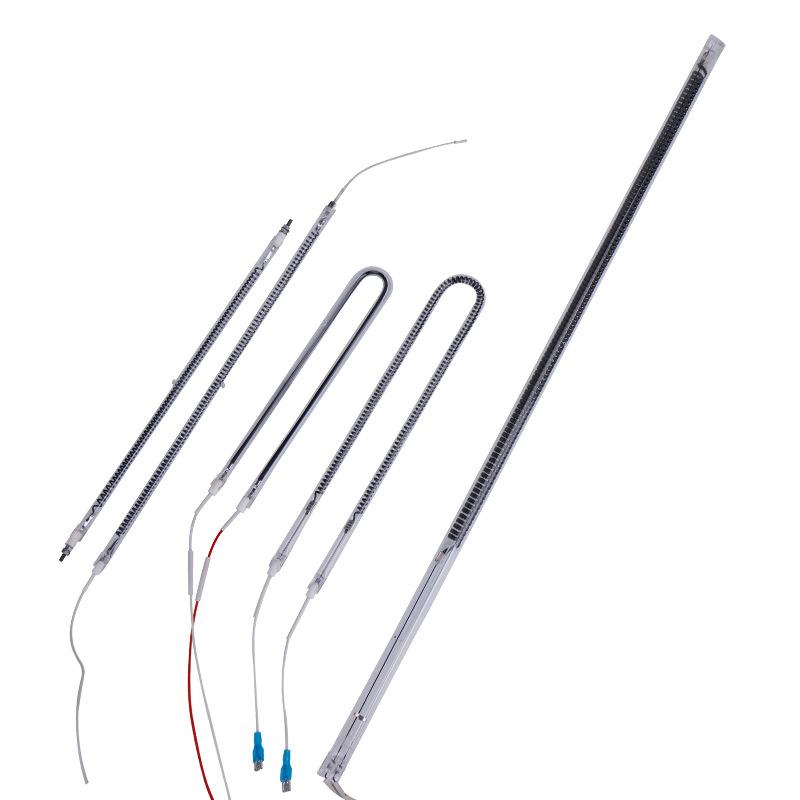

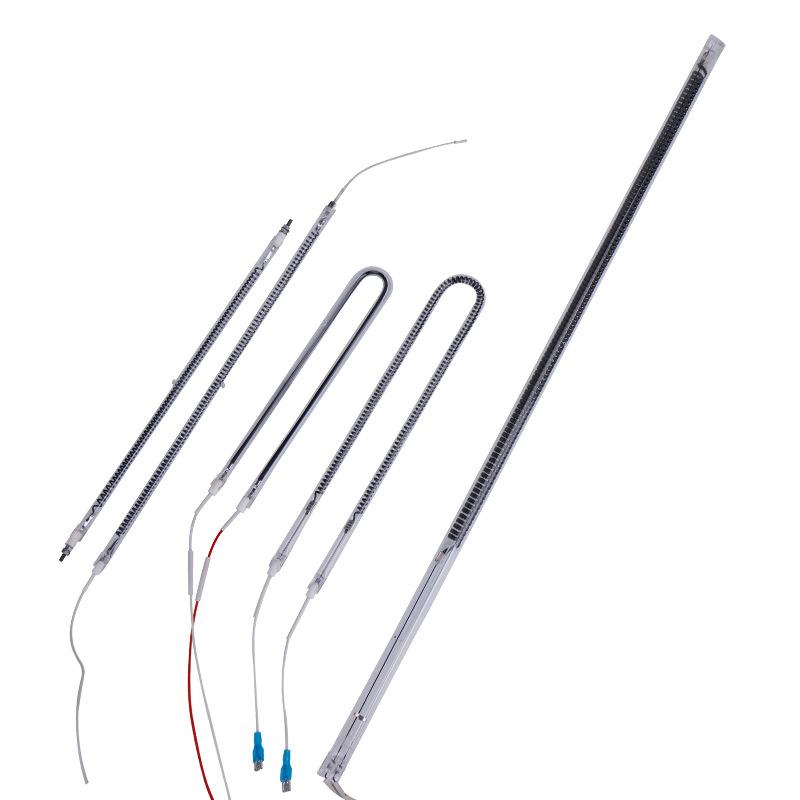

Carbon fiber heating Tube

- Product Details

What is a Carbon fiber heating Tube?

Carbon Fiber Heating Tubes are a type of infrared heating element that use carbon fiber as the primary material to generate heat. These heating tubes are commonly used in various applications ranging from home and industrial heating to specialized systems like saunas and automotive heating. Carbon fiber is known for its ability to conduct heat efficiently and for its flexibility and durability.

Key Characteristics of Carbon Fiber Heating Tubes

Material and Structure:

Carbon fiber is a composite material made of thin fibers that are mostly made up of carbon atoms. These fibers are typically combined with a resin to form a flexible or rigid structure.

In heating tubes, the carbon fiber is often woven into a mesh or strands, allowing it to efficiently convert electrical energy into infrared heat when an electric current passes through it.

Heating Mechanism:

Infrared Radiation: When an electrical current passes through the carbon fiber element, it heats up and emits infrared radiation, which directly heats objects and people in its path rather than heating the air.

Carbon fiber is an effective material for this purpose because it has relatively high resistance to heat and can generate significant infrared radiation without overheating.

Advantages of Carbon Fiber Heating Tubes:

Fast Heating: Carbon fiber heating elements are capable of producing heat relatively quickly, especially compared to conventional heating systems like water-based radiators or air-convection systems.

Energy Efficient: Carbon fiber heating tubes are efficient because they directly heat objects or people via infrared radiation, rather than heating the surrounding air. This reduces energy consumption and improves overall heating efficiency.

Durability: Carbon fiber is highly durable and resistant to wear, corrosion, and environmental stress. It can handle high temperatures without degrading, making it ideal for long-term use in a variety of conditions.

Flexibility: Many carbon fiber heating elements are designed to be flexible, making them ideal for applications that require bending or molding, such as underfloor heating, heating mats, or portable heaters.

Even Heat Distribution: Carbon fiber elements tend to generate a relatively even distribution of heat across their surface, which makes them ideal for heating large areas or specific targets without causing hotspots.

Lightweight: Carbon fiber is lightweight, making these heating elements easier to handle and install compared to traditional metal-based heating systems.

Disadvantages of Carbon Fiber Heating Tubes:

Slower Response: Although carbon fiber heats up quickly, its response time is generally slower compared to materials with higher thermal conductivity, like graphene. This means that while it generates heat efficiently, it may take slightly longer to reach the desired temperature.

Limited Thermal Conductivity: While carbon fiber has decent heat retention properties, it has lower thermal conductivity than metals like aluminum or copper. This means it may not be as efficient in transferring heat as some other materials.

Risk of Mechanical Damage: Carbon fiber, although durable, is still somewhat prone to damage from physical impact or bending beyond its specified limit. It may break or crack if subjected to too much force.

Applications of Carbon Fiber Heating Tubes:

Space Heating: Carbon fiber heating tubes are often used in electric space heaters. They can be used in both room heaters (such as wall-mounted or free-standing units) and portable heaters for personal use.

Underfloor Heating: Carbon fiber is commonly used in underfloor heating systems, especially in flexible mats or tapes that can be installed under tile, carpet, or hardwood floors.

Saunas: Carbon fiber heating elements are often used in infrared saunas, where they emit infrared heat that penetrates the body directly, promoting detoxification, relaxation, and improved blood circulation.

Automotive and RV Heating: Some vehicles, RVs, and boats use carbon fiber heating tubes for efficient cabin heating. These systems are often space-efficient and can be integrated into the vehicle’s existing electrical system.

Medical and Therapeutic Uses: Carbon fiber heating elements can be used in heat therapy devices, where infrared heat is applied to specific areas of the body for pain relief, muscle relaxation, or rehabilitation.

Industrial Applications: In industrial settings, carbon fiber heating tubes can be used for drying, curing paints, plastics processing, or materials testing that require controlled heating over a surface area.

Greenhouses: Carbon fiber heating systems are also used in greenhouses to maintain optimal temperatures for plant growth.

Technical Specifications:

Voltage: Typically designed to operate at standard voltages (e.g., 120V or 230V) for residential and commercial applications.

Power Ratings: Carbon fiber heating tubes can have power ratings ranging from 100W to several kilowatts, depending on the size and application of the system.

Temperature Range: The operating temperature for carbon fiber heating tubes can range between 300°C to 600°C (572°F to 1,112°F) depending on the design and intended use.

Lifespan: With proper maintenance, carbon fiber heating elements can last for 10-20 years or more, especially in applications where they are not subject to excessive mechanical stress.

Safety Features:

Overheating Protection: Many carbon fiber heating systems include built-in overheat protection mechanisms to prevent the element from reaching dangerous temperatures.

Automatic Shutoff: Some systems include an automatic shutoff feature if the heating element is left on for too long or if a malfunction is detected.

Low-EMF Emissions: Carbon fiber heating tubes emit low levels of electromagnetic fields (EMF), making them safer for long-term exposure compared to some other heating technologies.

-

Energy Saving Heating Tape Frost Protection for Pipes & Tanks

Enquire Now -

Industrial Heating Tape - Freeze Protection for Pipes & Roofs | Energy Efficient

Enquire Now -

DLX Durable & Efficient Anti-Freeze Heating Tape for Roof

Enquire Now -

DLX High Temp Heating Tape For Metal Pipes & Machinery

Enquire Now