Rod Ferro Alloy Metal with Supply State and Melting Point 1400-1520°C

- Product Details

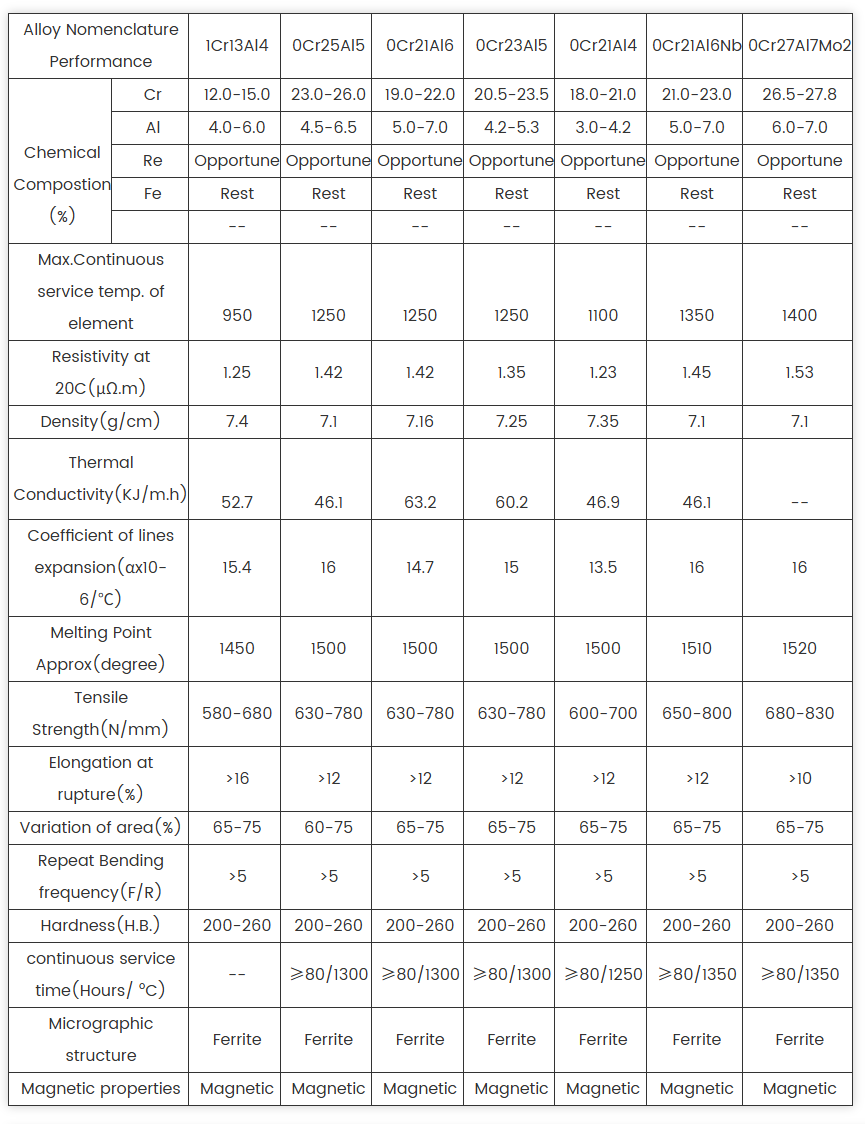

Product Description:

The FeCrAl Alloy can be manufactured in various lengths depending on the customer's requirement. Its density is 7.1, making it a lightweight and durable material for industrial applications. The bright status of the alloy enhances its aesthetic appeal and makes it ideal for decorative purposes.

One of the most significant advantages of the FeCrAl Alloy is its excellent corrosion resistance. The alloy can withstand harsh environments and is highly resistant to corrosion caused by acids, alkalis, and other corrosive materials. This unique feature makes it ideal for use in chemical and petrochemical industries.

The FeCrAl Alloy contains 80% nickel, which provides it with exceptional mechanical properties. It has high-temperature strength, making it ideal for use in high-temperature applications such as furnace heating elements, kilns, and industrial ovens. The alloy is also known for its low thermal expansion coefficient, which makes it resistant to thermal stress and thermal shock.

In summary, the FeCrAl Alloy is an exceptional Iron-Base Alloy that is widely used in various industries due to its exceptional properties. Its Ferritic Stainless Steel composition, lightweight, and excellent corrosion resistance make it ideal for use in chemical and petrochemical industries. Its 80% nickel composition provides it with exceptional mechanical properties, making it ideal for high-temperature applications. Its low thermal expansion coefficient makes it resistant to thermal stress and thermal shock. The FeCrAl Alloy is a reliable and durable material that can withstand harsh environments, making it a popular choice for industrial applications.

For more details, pls directly contact us.

Applications:

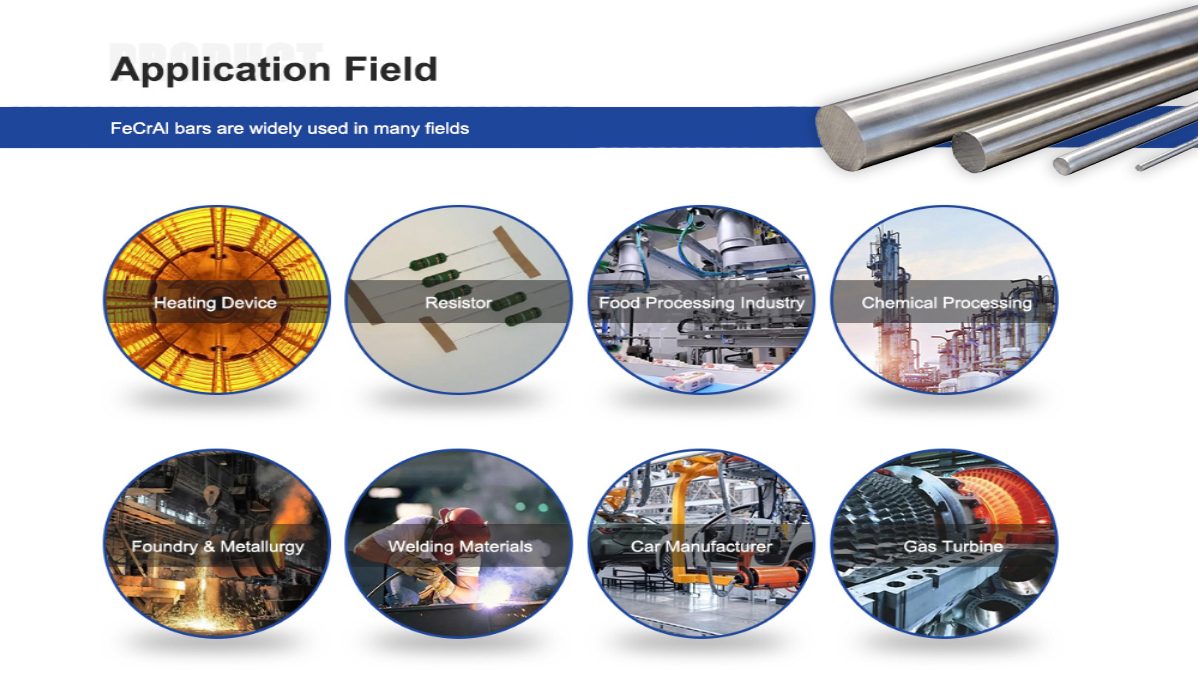

One of the main applications for DLX's FeCrAl Alloy is in the production of Ferro Silicon Alloy. Ferro Silicon Alloy is used in the production of steel and other alloys, and the FeCrAl Alloy is an essential component in its production. The FeCrAl Alloy's excellent corrosion resistance makes it an ideal choice for use in the production of Ferro Silicon Alloy.

Another application for DLX's FeCrAl Alloy is in the production of Ferritic Stainless Steel. Ferritic Stainless Steel is a type of stainless steel that is known for its excellent corrosion resistance and high-temperature strength. The FeCrAl Alloy's high tensile strength of 600-800 MPa and excellent corrosion resistance make it an ideal choice for use in the production of Ferritic Stainless Steel.

The FeCrAl Alloy is also used in various other applications, such as heating elements, industrial furnaces, and electrical resistance wires. The FeCrAl Alloy's high-temperature strength and thermal expansion rate make it an ideal choice for use in these applications.

The length of the FeCrAl Alloy can be customized to meet the specific requirements of the customer. DLX's FeCrAl Alloy product is of high quality, and its excellent corrosion resistance, high-temperature strength, and thermal expansion rate make it an ideal choice for various applications across different industries.

Support and Services:

Our FeCrAl alloy product is designed to provide high levels of resistance to oxidation and corrosion, making it ideal for use in a variety of applications. Our technical support team is available to provide assistance with product selection, performance optimization, and troubleshooting. We also offer a range of services, including product customization, testing, and analysis. Our goal is to ensure that our customers have access to the resources they need to get the most out of our FeCrAl alloy product.

Packing and Shipping:

Product Packaging:

The FeCrAl alloy product will be packaged in a sturdy cardboard box with sufficient padding to prevent damage during transportation. Each box will contain the product, along with any necessary instructions and safety information.

Shipping:

The FeCrAl alloy product will be shipped via a reliable courier service, such as UPS or FedEx, to ensure timely and secure delivery. Shipping costs will be calculated based on the destination and weight of the package. Customers will be provided with a tracking number to monitor the delivery status of their order.

About Us:

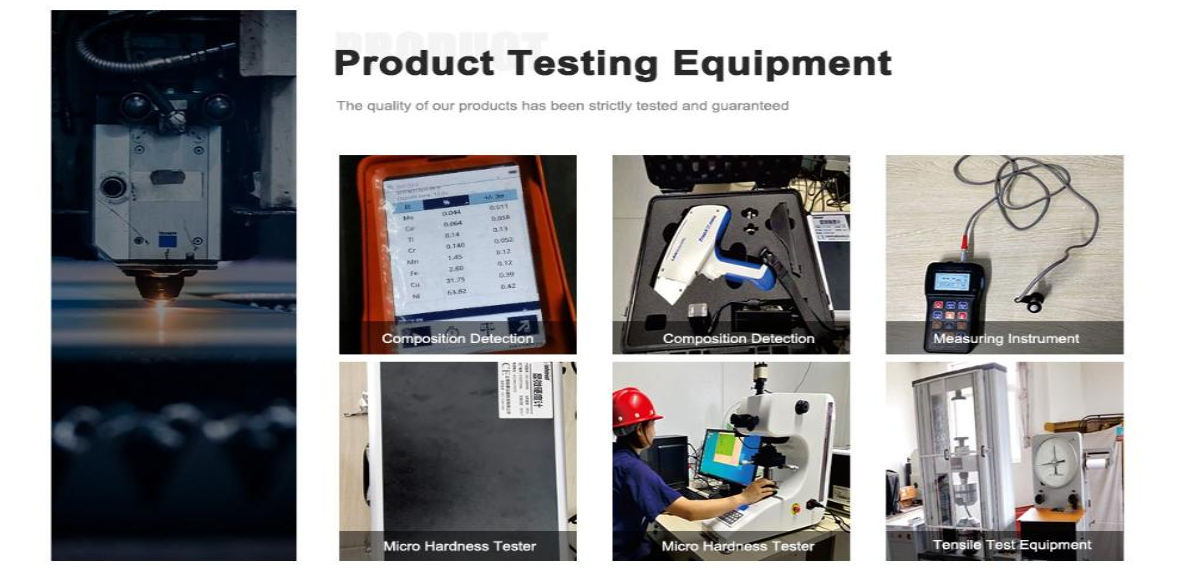

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

A: DLX FeCrAl Alloy is a high-resistance alloy made of iron, chromium, and aluminum. It is widely used in heating elements, industrial furnaces, and other high-temperature applications.

2. Q: What is the maximum operating temperature of DLX FeCrAl Alloy?

A: The maximum operating temperature of DLX FeCrAl Alloy is around 1300°C (2372°F). However, this may vary depending on the specific grade and application.

3. Q: What are the advantages of using DLX FeCrAl Alloy over other heating elements?

A: DLX FeCrAl Alloy has several advantages over other heating elements, including high resistance to oxidation and corrosion, excellent mechanical strength, and good ductility. It also has a low temperature coefficient of resistance, which means it maintains its resistance under varying temperatures.

4. Q: Can DLX FeCrAl Alloy be customized according to specific requirements?

A: Yes, DLX FeCrAl Alloy can be customized according to specific requirements, including size, shape, and resistance. Please contact our sales team for more information.

5. Q: Where is DLX FeCrAl Alloy manufactured?

A: DLX FeCrAl Alloy is manufactured in China, where we have a dedicated production facility that uses advanced equipment and techniques to ensure consistent quality and performance.

-

Bright Annealed FeCrAl Alloy with Excellent Oxidation Resistance and Tensile Strength 700MPA

Enquire Now -

Chromium Cast Iron Bar for Corrosion and Oxidation Resistance

Enquire Now -

FeCrAl Alloy Bar with Excellent Corrosion Resistance for Extreme Conditions

Enquire Now -

1250C-1500C Iron Chromium Melting Point chromium aluminum Strip for Superior Resistance and Welding

Enquire Now