FeCrAl Alloy The Superior Choice for sale

| Product Details | |

| Place Of Origin | China JiangSu |

Brand Name | DLX |

Model Number | FeCrAl |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

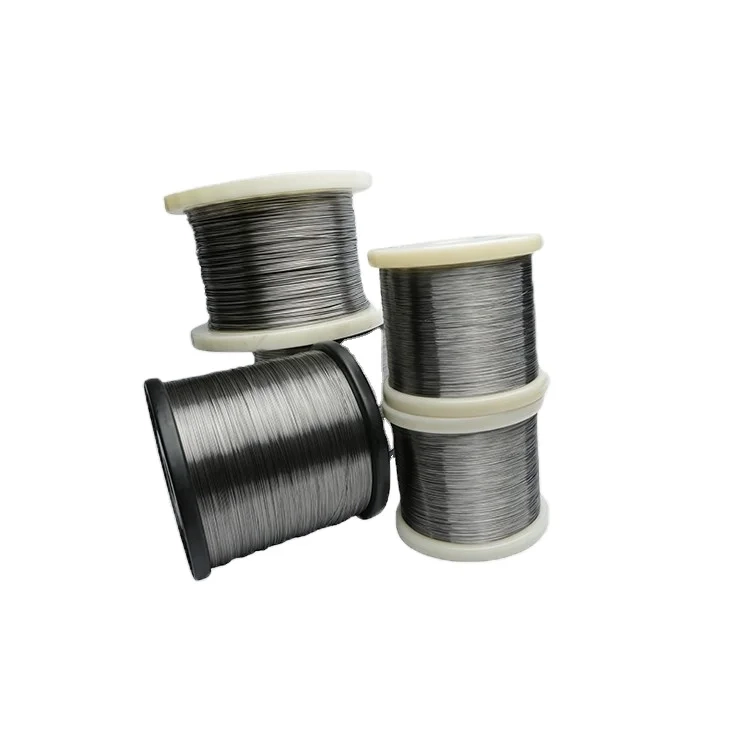

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Ferrous Chromium Aluminum alloy performance tables

| Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Main Chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max. continuous service temp. of element(°C) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity at 20ºC(μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity(KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | ||

| Coefficient of lines expansion(α×10-6/ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Melting point approx.( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Continuous Servicetime(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic |

Magnetic | |

Product Description:

The FeCrAl alloy is available in both hard and soft conditions, depending on the application requirements. The hard condition is used when high mechanical strength is needed, while the soft condition is used when good ductility is required. The alloy can be heat treated in various ways, including bright, oxidized, and acide, depending on the desired properties.

The FeCrAl alloy is known for its high elongation, which is ≥25%, making it an ideal choice for applications that require flexibility and resistance to deformation. The alloy's magnetic properties make it well-suited for use in electrical heating elements, where it can be easily magnetized and demagnetized.

The FeCrAl alloy is widely used in many industries, including automotive, aerospace, and electronics. It is commonly used in heating elements for industrial furnaces, kilns, and ovens, as well as in electric heating appliances such as toasters, hair dryers, and coffee makers. The alloy's excellent oxidation resistance also makes it suitable for use in the production of catalytic converters and other high-temperature applications.

In conclusion, the FeCrAl alloy, also known as Resistohm 135 or Aluchrom S, is a high-resistance alloy that is widely used in various heating applications. It is known for its excellent oxidation resistance, high elongation, and magnetic properties, making it an ideal choice for applications that require flexibility, resistance to deformation, and easy magnetization. The alloy is available in both hard and soft conditions and can be heat treated in various ways to achieve the desired properties.

Features:

Product Name: FeCrAl Alloy

Elongation: ≥25%

Density: 7.2-7.7g/cm3

Tensile Strength: 630-780MPA

Condition: Hard / Soft

Corrosion Resistance: Excellent

Aluminium Chromium Alloy: Aluchrom S

Iron Chromium: Yes

Technical Parameters:

| Material | FeCrAl Alloy |

| Corrosion Resistance | Excellent |

| Density | 7.2-7.7g/cm3 |

| Melting Point | 1250℃-1500℃ |

| Formability | Excellent |

| Oxidation Resistance | Excellent |

| Heat Treatment | Bright, Oxided, Acide |

| Magnetic Property | Ferromagnetic |

| Tensile Strength | 630-780MPA |

| Weldability | Excellent |

This table shows the technical parameters of a FeCrAl Alloy product. FeCrAl Alloy is also known as chromium aluminum alloy or high chromium cast iron. It is known for its excellent corrosion resistance, formability, oxidation resistance, and weldability. It has a density of 7.2-7.7g/cm3 and a melting point of 1250℃-1500℃. It can be heat treated using bright, oxided, or acide methods. It is ferromagnetic and has a tensile strength of 630-780MPA.

Applications:

The excellent formability of DLX's FeCrAl alloy makes it ideal for use in a wide range of scenarios. It can be easily formed into different shapes, making it perfect for use in the production of heating elements, resistance wire, and other electrical components. The product's excellent corrosion resistance also makes it an ideal choice for use in harsh environments, such as chemical processing plants and marine environments.

The tensile strength of DLX's FeCrAl alloy ranges from 630-780MPA, making it an excellent choice for applications that require high strength and durability. Its excellent oxidation resistance makes it ideal for use in high-temperature applications, such as furnace heating elements and other high-temperature processing equipment.

DLX's FeCrAl alloy product is a magnetic material, making it suitable for use in magnetic applications. Its high chrome iron and aluminium chromium alloy composition makes it an excellent choice for applications that require a combination of high strength, excellent formability, and resistance to corrosion and oxidation.

Overall, DLX's FeCrAl alloy product is a versatile, high-quality material that can be used in a wide range of applications. Its excellent formability, corrosion resistance, tensile strength, and oxidation resistance make it an ideal choice for use in electrical components, chemical processing plants, marine environments, and high-temperature applications.

Customization:

DLX offers product customization services for FeCrAl alloy, also known as iron chromium. Our FeCrAl alloy, Aluchrom S, is sourced from China JiangSu, and is available in both hard and soft conditions. The ferromagnetic material can undergo different heat treatments such as bright, oxided, and acide. The excellent formability of the alloy makes it suitable for customizing products to meet specific requirements. The density of our FeCrAl alloy ranges from 7.2-7.7g/cm3.

Support and Services:

The FeCrAl Alloy product technical support and services include:

- Troubleshooting assistance

- Material selection guidance

- Custom alloy development

- Failure analysis

- Technical data and literature

- Certification and testing support

- On-site technical consultation

Packing and Shipping:

Product Packaging:

The FeCrAl Alloy product will be packaged securely in a cardboard box with appropriate padding to prevent damage during transit. The box will be labeled with the product name, quantity, and any necessary handling instructions.

Shipping:

The FeCrAl Alloy product will be shipped via a reputable courier service to the destination provided by the customer. The shipping cost will be calculated based on the weight and destination of the package. Customers will be provided with a tracking number to monitor the progress of their shipment.

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is DLX.

Q: What is the model number of this product?

A: The model number of this product is FeCrAl.

Q: Where is this product made?

A: This product is made in China JiangSu.

Q: What is FeCrAl alloy?

A: FeCrAl alloy is a high-resistance material made from iron, chromium, and aluminum. It is commonly used in industrial heating applications due to its excellent resistance to oxidation and high temperatures.

Q: What are the applications of FeCrAl alloy?

A: FeCrAl alloy is commonly used in heating elements, furnace components, and electrical appliances.