FeCrAl Alloy The Best Heating Material for sale

| Product Details | |

| Place Of Origin | China JiangSu |

Brand Name | DLX |

Model Number | FeCrAl |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

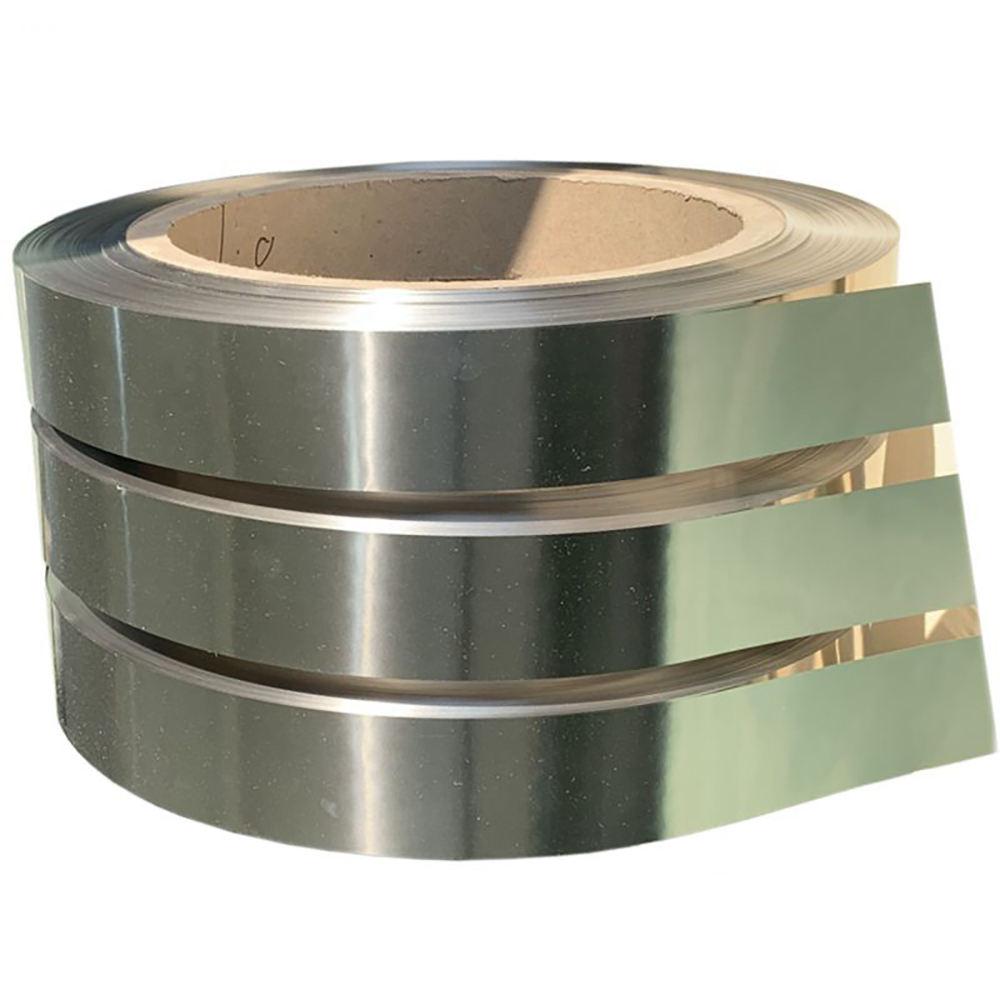

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Ferrous Chromium Aluminum alloy performance tables

| Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Main Chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max. continuous service temp. of element(°C) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity at 20ºC(μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity(KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | ||

| Coefficient of lines expansion(α×10-6/ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Melting point approx.( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Continuous Servicetime(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic |

Magnetic | |

Product Description:

This alloy is used in a wide range of applications, including heating elements, resistors, and electric heating appliances. It is also used in the production of various types of furnaces, kilns, and ovens.

The heat treatment of FeCrAl alloy can be bright, oxidized, or acide, depending on the intended use of the product. The bright heat treatment provides a smooth and shiny surface, while the oxidized heat treatment creates a layer of oxide on the surface that helps protect against corrosion. The acide heat treatment enhances the corrosion resistance of the alloy.

One of the key benefits of using FeCrAl alloy is its excellent formability. This makes it ideal for use in a wide range of applications that require complex shapes or intricate designs. The alloy can be easily formed, bent, and shaped without losing its mechanical properties.

In addition to its formability, FeCrAl alloy is also known for its excellent corrosion resistance. The aluminium chromium alloy composition provides a high level of protection against corrosion and oxidation, making it ideal for use in harsh environments or applications where the product will be exposed to corrosive materials.

FeCrAl alloy also has a high tensile strength of 630-780MPA, which makes it ideal for use in high-stress applications. The material can withstand significant amounts of pressure and stress without losing its structural integrity.

In conclusion, FeCrAl alloy is a versatile and reliable material that can be used in a wide range of applications. Its excellent formability, corrosion resistance, and tensile strength make it ideal for use in a variety of industries, including the heating and electrical industries. So, if you are looking for a material that can provide reliable performance and durability, consider using FeCrAl alloy.

Features:

Product Name: FeCrAl Alloy (Aluchrom S)

Density: 7.2-7.7g/cm3

Magnetic Property: Ferromagnetic

Corrosion Resistance: Excellent

Material: FeCrAl Alloy (high chromium cast iron)

Condition: Hard / Soft

Technical Parameters:

| Magnetic Property | Ferromagnetic |

| Density | 7.2-7.7g/cm3 |

| Condition | Hard / Soft |

| Melting Point | 1250℃-1500℃ |

| Oxidation Resistance | Excellent |

| Weldability | Excellent |

| Tensile Strength | 630-780MPA |

| Material | FeCrAl Alloy (Aluchrom S) |

| Formability | Excellent |

| Elongation | ≥25% |

Applications:

The FeCrAl alloy is a ferromagnetic material that is widely used in the production of electrical heating elements, industrial furnaces, household appliances, and other high-temperature resistance products. Due to its high chromium content, FeCrAl alloy has excellent oxidation and corrosion resistance, making it ideal for use in high-temperature environments.

The FeCrAl alloy is widely used in the heating industry, such as in hot strips, infrared heaters, ceramic heaters, and other heating appliances. The material is also used in the production of industrial furnaces, such as the heating coil, radiant tube, and heat treatment furnace, due to its excellent oxidation resistance and high-temperature strength.

The FeCrAl alloy is also used in household appliances, such as hair dryers, toasters, and other heating appliances. Due to its excellent heat resistance, the FeCrAl alloy can withstand high temperatures and maintain its shape, making it ideal for use in household appliances.

Moreover, the FeCrAl alloy is widely used in the automotive industry to manufacture exhaust systems. The material is used to make exhaust pipes, mufflers, and catalytic converters due to its excellent corrosion and oxidation resistance. FeCrAl alloy is more durable than high chromium cast iron and aluminium chromium alloy, making it an ideal material for automotive exhaust systems.

In summary, DLX FeCrAl alloy is a versatile material that can be used in various applications, such as electrical heating elements, industrial furnaces, household appliances, and automotive exhaust systems. The material has excellent oxidation and corrosion resistance, excellent weldability, and a density of 7.2-7.7g/cm3, making it an ideal choice for high-temperature resistance products.

Support and Services:

Our FeCrAl alloy products are designed to provide high-temperature resistance, excellent oxidation resistance, and long-term stability in various industrial applications. We offer technical support and services to ensure that our customers get the best product performance and reliability.

Our technical support team can assist with product selection, application analysis, and troubleshooting. We also offer customization services to meet specific customer requirements.

In addition, we provide services such as alloy testing, material analysis, and failure analysis to help customers optimize their processes and improve product performance.

Our commitment to quality and customer satisfaction ensures that we provide timely and effective technical support and services to our customers.

Packing and Shipping:

Product Packaging:

The FeCrAl Alloy product will be packaged in a sturdy cardboard box with internal cushioning to prevent any damage during transit. Each box will contain a set amount of product as per the customer's order and will be labeled with the product name and quantity for easy identification.

Shipping:

The FeCrAl Alloy product will be shipped via a reputable courier service to ensure timely and safe delivery. Customers will be provided with a tracking number to monitor the progress of their shipment. Shipping costs will vary depending on the destination and weight of the order, and will be calculated and included in the final invoice.

FAQ:

Q1: What is the brand name of the FeCrAl Alloy product?

A1: The brand name of this product is DLX.

Q2: What is the model number of the FeCrAl Alloy product?

A2: The model number of this product is FeCrAl.

Q3: Where is the FeCrAl Alloy product manufactured?

A3: The FeCrAl Alloy product is manufactured in China JiangSu.

Q4: What are the common applications of the FeCrAl Alloy product?

A4: The FeCrAl Alloy product is commonly used in high-temperature heating elements, industrial furnaces, and other high-temperature applications.

Q5: What are the physical properties of the FeCrAl Alloy product?

A5: The FeCrAl Alloy product has a high melting point, high electrical resistance, and excellent oxidation resistance at high temperatures. It also has good ductility and can be easily formed and welded.