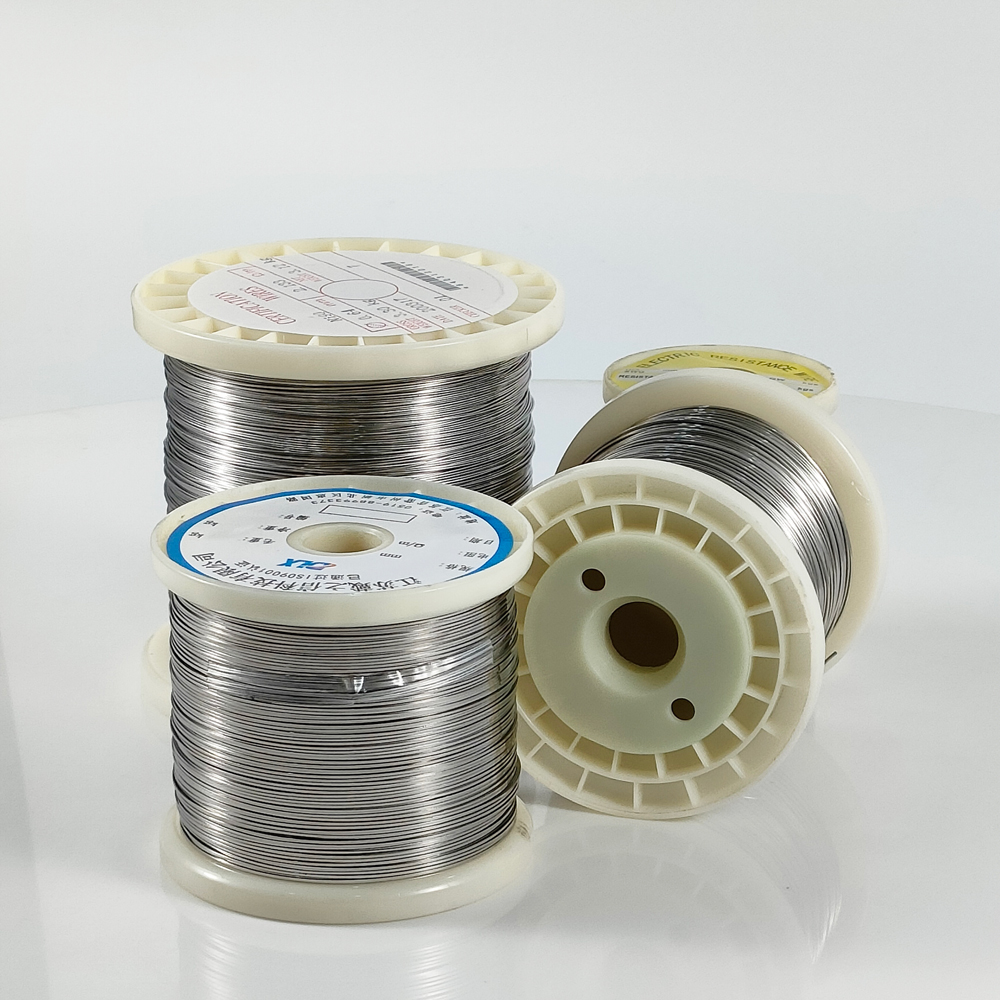

FeCrAl Alloy 0Cr25Al5 Grade 255 Heating Resistance Wire

In the resistance wire category, there are FeCrAl alloy, Nichrome alloy, CuproNickel alloy, and NiFe alloy. They have quite different resistivity due to different chemical compositions.

The one we are to introduce today is FeCrAl alloy, a high-resistivity alloy. According to the statistics, over 69% of Industrial heating is contributed by FeCrAl alloy.

Grade 255(0Cr25Al5) is often mentioned in the first because of its high resistivity. Let's have a look at its datasheet.

| Grade | Chemical Composition(%) | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| Less than | |||||||||

| 255 | 0.06 | 0.025 | 0.02 | 0.5 | 0.6 | 23-26 | ≦0.6 | 5.0~7.0 | Bal |

Note: DLX Alloy produces Grade 255 in the standard of GB/T1234-2012.

If we study the composition, we can find that

Iron(Fe) takes about 66%, which makes FeCrAl alloy the most economical electrical resistance material.

Chromium(Cr):23%-26%, enhances oxidation, high-temperature, and sulfidation resistance.

Aluminum(Al):5.0%~7.0%. During the heating process, Al2O3 film will be generated on the surface to protect the resistance wire.

Nickel(Ni):0.6%, provides metallurgical stability, and improves thermal stability and weldability.

Other elements take small percentages and they must be kept small. Otherwise, the wires will be stiff and brittle. DLX ALLOY sticks to using 100% New material to guarantee the composition.

Since the 0Cr25Al5 composition is confirmed, we need to focus on its top advantage: Resistivity.

FeCrAl alloy Grade 255 resistivity at 20°C is 1.42 ųΩ•m, tolerance is ±0.07. Here I listed some running sizes and their ohms per meter.

| Size(mm) | Ohm/Mtr (Ω) | Tolerance(%) |

| 0.02 | 4522 | ±15 |

| 0.07 | 369 | ±8 |

| 0.1 | 180.8 | ±8 |

| 0.2 | 45.2 | ±6 |

| 0.5 | 7.23 | ±5 |

| 1.0 | 1.808 | ±5 |

| 2.0 | 0.452 | ±5 |

| 3.0 | 0.2 | ±5 |

| 5.0 | 0.072 | ±5 |

How to calculate the resistance if I have 500mm wire? There is a formula:

R=p*L/S

R is the resistance, unit is Ω

p is the resistivity, unit is ųΩ•m

L is the length of wire, unit is meter

S is the cross section, unit is mm2

So suppose you have 0.5mtr long Grade 255 0.2mm dia wire, its resistance is around 90ohm.

This formula suits for all the wires to calculate resistance. How much resistance are you looking for? We are good at calculating and help you find the right resistance wires.

Ferrous Chromium Aluminum alloy performance tables

| Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Main Chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max. continuous service temp. of element(°C) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity at 20ºC(μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity(KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | ||

| Coefficient of lines expansion(α×10-6/ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Melting point approx.( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Continuous Servicetime(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic |

Magnetic | |