1.45 μΩ·m High Temperature Annealed Fecral Wire / Alloy Fecral Wire In Coils

- Product Details

Our 1.45 μΩ·m high-temperature annealed FeCrAl wire, delivered in coils, is a total rockstar for industrial heating applications, and we’re thrilled to share why it’s such a standout. This iron-chromium-aluminum alloy is engineered to deliver killer performance in extreme heat and harsh environments, perfect for manufacturers who need reliability and efficiency.

This FeCrAl wire, typically with 20-25% chromium and 5-6% aluminum (like 0Cr27Al7Mo2 or Kanthal A-1), is built to handle temperatures up to 1400°C, making it ideal for industrial furnaces, kilns, or coiled heating elements. The annealing process softens the wire, boosting its formability so we can wind it into tight, precise coils without cracking—perfect for compact or intricate designs. Its oxidation resistance is next-level, forming a protective Al2O3 oxide layer above 1000°C that shields it from degradation in sulfur-rich or acidic atmospheres.

With an electrical resistivity of 1.45 μΩ·m, this wire generates heat super efficiently, ensuring consistent performance in heating elements or resistors. Its corrosion resistance is top-notch, holding strong in chemical processing or metallurgical environments. The tensile strength (~550-600 MPa post-annealing) keeps it durable, and its thermal conductivity (~11-13 W/mK) ensures steady heat distribution. We supply it in coils of various gauges, ready for everything from precision heaters to heavy-duty industrial systems.

The industry in 2025 is all about high-performance and sustainability, and our FeCrAl wire is right on trend. There’s a massive demand for heat-resistant, corrosion-resistant materials in aerospace, automotive, and energy sectors, like EV battery systems, turbine components, or ceramic firing kilns. Being 100% recyclable, it’s a great fit for eco-friendly manufacturing. As high-temperature automation and efficiency keep trending, this wire’s high resistivity and annealed flexibility make it a top pick for cutting-edge applications.

Sure, Nichrome Cr20Ni80 is a bit more formable and great for lower-temperature setups, but our FeCrAl wire’s higher heat tolerance and oxidation resistance make it the champ for extreme environments. Stainless Steel 316 is corrosion-resistant but can’t match FeCrAl’s high-temperature performance or resistivity. Just watch out for creep at max temps, though this wire handles most industrial conditions like a pro.

From coiled heating elements to industrial furnaces, our 1.45 μΩ·m annealed FeCrAl wire delivers the heat resistance, reliability, and efficiency that keep industries blazing forward.

Product Description:

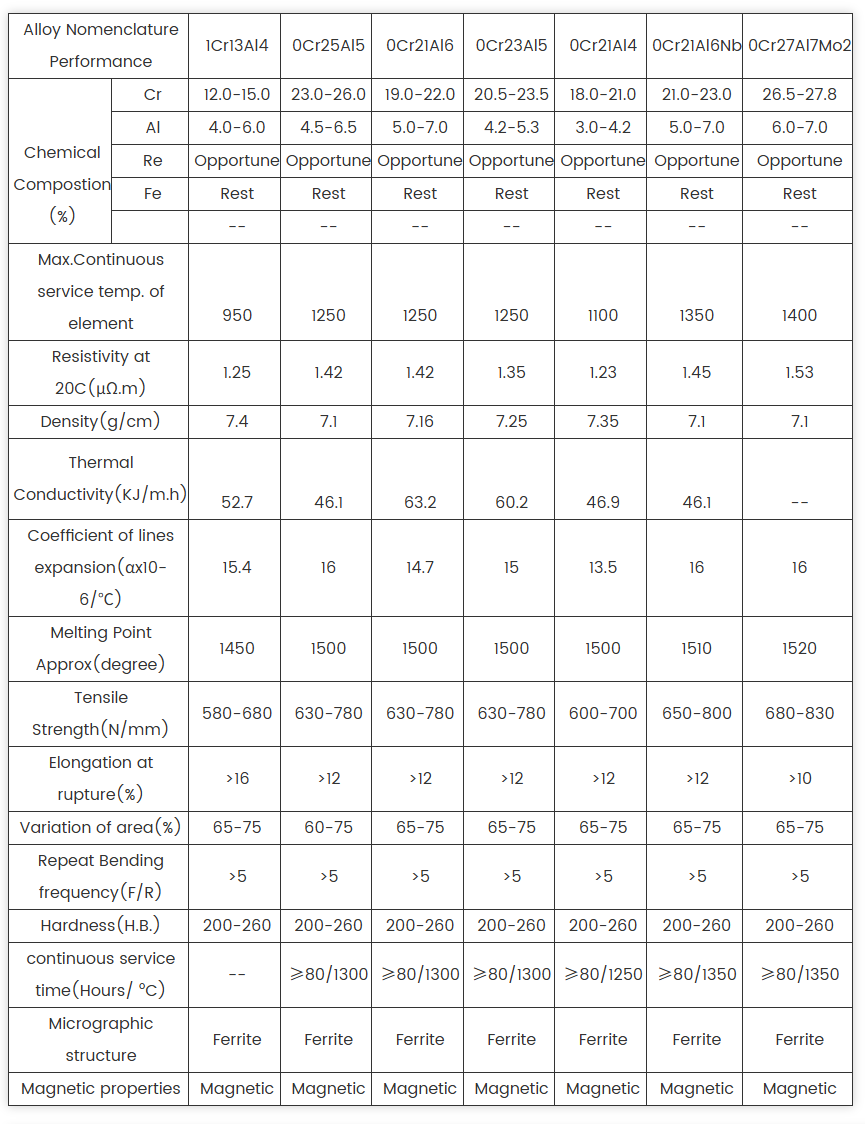

One of the key features of FeCrAl wire is its resistivity. It has a resistivity of 1.35 - 1.45 μΩ·m, which means that it can withstand high temperatures and has excellent electrical conductivity. This makes it an ideal material for use in electric heating elements, including industrial furnaces, household appliances, and heating coils.

FeCrAl Wire comes in two forms: Bare Copper FeCrAl Wire and Copper Clad Steel Wire. The bare copper wire is used for applications where the wire needs to be insulated, while the copper-clad steel wire is used for applications where the wire needs to be more durable and resistant to corrosion.

FeCrAl Wire is packed on spools or in coils, depending on the customer's requirements. This makes it easy to handle and transport, and ensures that the wire is protected from damage during shipping and storage.

Another important feature of FeCrAl Wire is its melting point. It has a melting point of 1500°C, which makes it highly resistant to heat. This means that it can be used in applications where high temperatures are required, such as in industrial furnaces and ovens.

FeCrAl Wire is available in a variety of surface finishes, including bright, oxidized, and acid. The bright surface finish is ideal for applications where a clean, polished appearance is required, while the oxidized and acid finishes are more suitable for applications where corrosion resistance is important.

Finally, FeCrAl Wire has magnetic properties, which makes it suitable for use in applications where magnetic fields are required, such as in transformers and electric motors. Its magnetic properties also make it easier to handle and manipulate during the manufacturing process.

Applications:

The DLX FeCrAl wire is commonly used in heating and resistivity applications. The wire is ideal for use in heating elements, where it can withstand high temperatures and maintain its resistivity. It is also commonly used in resistive heating applications, such as in industrial furnaces and ovens.

The wire is also used in the production of copper clad steel wire. Copper clad steel wire is a composite wire that is made by wrapping a layer of copper around a steel wire. The copper layer provides excellent conductivity, while the steel wire provides strength and durability. The FeCrAl wire is used in the production of the steel wire, providing high-temperature resistance and durability.

TheDLX FeCrAl wire has a tensile strength of ≥ 650 MPa, making it strong and durable. This wire can be used in a variety of industrial applications, including the production of heating elements, industrial furnaces, and ovens. The wire is also commonly used in the production of resistive heating elements, such as in electric stoves and heaters.

In summary, the DLX FeCrAl wire is a high-quality alloy wire that is made in China Jiangsu. It is ideal for use in applications that require resistance to high temperatures, such as heating and resistivity applications. The wire is commonly used in the production of copper clad steel wire, providing high-temperature resistance and durability. With a tensile strength of ≥ 650 MPa, this wire is strong and durable, making it suitable for a variety of industrial applications.

Customization:

Brand Name: DLX

Model Number: FeCrAl

Place of Origin: China JiangSu

Magnetic Properties: Magnetic

Material: FeCrAl (Iron-Chromium-Aluminum)

Surface: Bright, Oxided, Acide

Melting Point: 1500°C

Elongation: ≥12%

We offer customization services for a variety of FeCrAl wire products, including Black Annealed Tie Wire, Bare Copper FeCrAl Wire, and Annealed FeCrAl Wire. Contact us today to discuss your specific customization needs.

Support and Services:

Our FeCrAl wire is designed to resist high temperatures and oxidation, making it perfect for use in heating elements, resistors, and other high-temperature applications. Our technical support team is available to assist with any questions you may have regarding the use and application of our FeCrAl wire products, as well as to provide guidance on installation and maintenance. We also offer a range of services to support our wire products, including custom cutting and shaping, packaging, and labeling.

Packing and Shipping:

Product Packaging:

The FeCrAl wire product will be packed in a neat and secure manner to avoid any damage during shipping.

The wire will be wound around a spool and then placed in a cardboard box.

The box will be sealed with tape and labeled with product information and handling instructions.

Shipping:

The FeCrAl wire product will be shipped via a reliable courier service.

The shipping cost will be calculated based on the weight and destination of the package.

The estimated delivery time will depend on the shipping method chosen and the destination.

The customer will receive a tracking number to monitor the status of their shipment.

About Us:

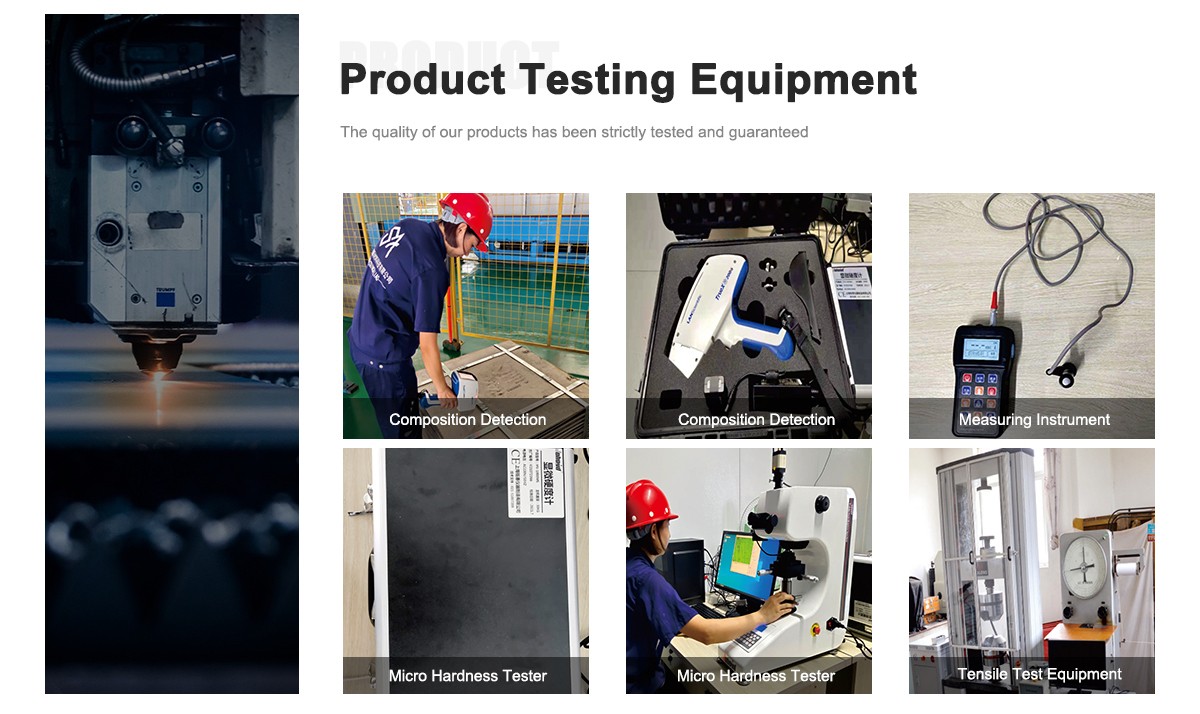

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Why use 1.45 μΩ·m FeCrAl wire for high-temperature applications?

Its high resistivity and heat stability make it perfect for efficient heating in extreme conditions.

What does annealing do for this FeCrAl wire?

It softens the wire, improving flexibility and making it easier to coil or shape.

Can this wire withstand extreme industrial temperatures?

Yup, it’s stable up to 1400°C, ideal for furnaces and kilns.

Is this FeCrAl wire corrosion-resistant?

Totally, it resists corrosion in harsh environments like chemical or sulfur-rich settings.

What’s the benefit of its high electrical resistivity?

It ensures efficient heat generation, great for consistent heating elements.

Is this FeCrAl wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in coiled heating elements?

Absolutely, its annealed flexibility is perfect for tight, reliable coils.

Is this FeCrAl wire cost-effective for industrial use?

Yes, its durability and performance make it a solid long-term investment.

-

What is FeCrAl Fiber Felt?

Enquire Now -

0Cr27Al7Mo Heating Resistance Wire (2.0mm Diameter) – Specifications

Enquire Now -

0Cr21Al6 FeCrAl Wire Corrosion Resistance Heating Electric Resistance Alloy Wires for Household App

Enquire Now -

Heating Element Wire Resistance Wire FeCrAl Alloy Wire With Superior Quality

Enquire Now