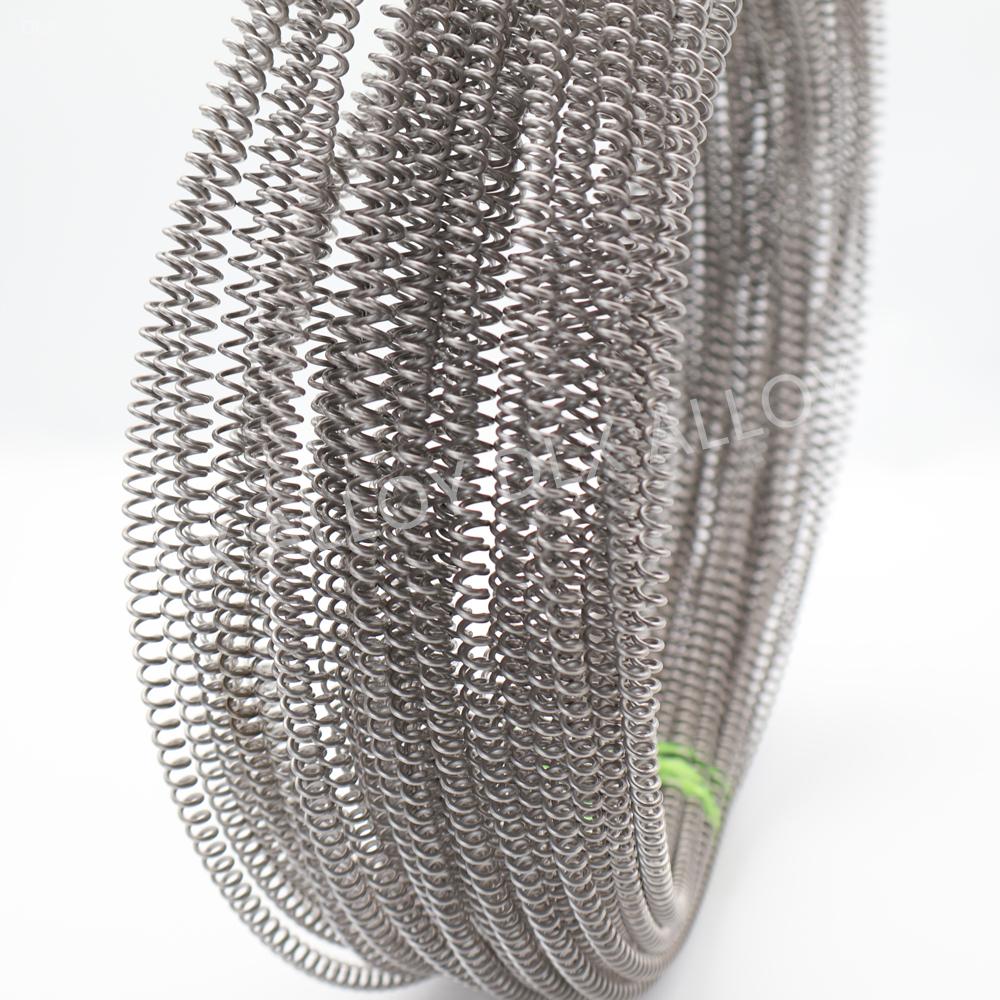

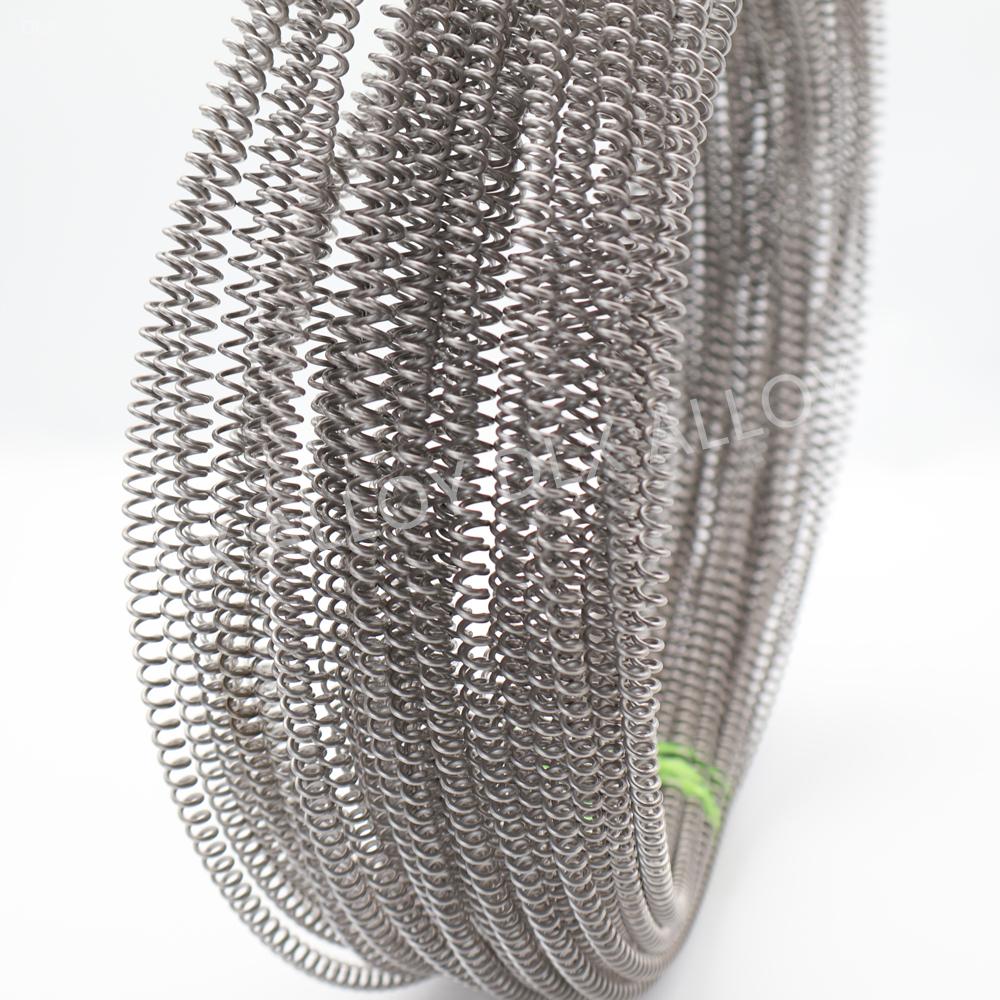

0Cr27Al7Mo Heating Resistance Wire (2.0mm Diameter) – Specifications

- Product Details

0Cr27Al7Mo Heating Resistance Wire (2.0mm Diameter) – Specifications

Material Composition:

0Cr27Al7Mo is a Fe-Cr-Al-Mo (Iron-Chromium-Aluminum-Molybdenum) alloy known for its high-temperature resistance, excellent oxidation resistance, and long service life.

Chromium (Cr): ~27%

Aluminum (Al): ~7%

Molybdenum (Mo): ~0.5-1.0%

Iron (Fe): Balance

Rare Earth Elements (REEs): Small amounts to improve performance

Physical & Electrical Properties:

Wire Diameter:2.0mm

Density:~7.2 g/cm³

Melting Point:~1500°C (2732°F)

Maximum Operating Temperature:~1400°C (2552°F)

Electrical Resistivity:~1.45 Ω·mm²/m

Resistance per Meter (Approx.):~0.46 Ω/m

Mechanical Properties:

Tensile Strength:~650-800 MPa

Elongation at Break:10-15%

Hardness: Moderate, slightly brittle at high temperatures

Key Features & Advantages:

✔ Higher temperature tolerance (up to 1400°C) than Nichrome .

✔ Excellent oxidation and corrosion resistance due to the aluminum oxide layer.

✔ Molybdenum (Mo) improves strength and high-temperature stability.

✔ Longer lifespan compared to standard FeCrAl and Nichrome wires.

Common Applications:

Industrial Furnaces & Kilns – High-temperature heating elements.

Electric Heating Equipment – Air heaters, ceramic kilns, heat treatment ovens.

Resistive Heating Elements – Used in extreme heat applications.

Metallurgical & Glass Industries – For heating crucibles and refractory equipment.