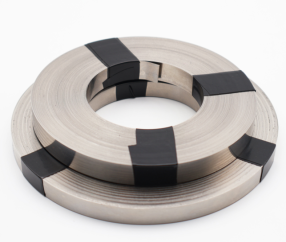

Ni-Span C902/3J53 Elastic Alloy

Release time:2025-03-09 Strike:162 Inquire Now

Precision Alloy-3J53

3J53 Alloy is the name in the Chinese Standard GB/T 15018-1994 Precision Alloy. In other countries' standards, they named differently.

| Russia | China | USA | France | Japan |

| 42HXTЮ | 3J53 | Ni-Span C902 | Ni-Span C | Sumispan-3 |

The first alloys developed for constant modulus purposes were binary iron-nickel compositions. A zero temperature coefficient is obtained

with alloys containing about 27% or 44% nickel, balance iron. These two alloys were found to be too sensitive to small changes in composition to be suitable for commercial production, a variation of 1% in nickel

content shifting the coefficient of the 44% alloy about 50 x 106/°F.

3J53 Elastic Alloy Chemical Composition:

| Grade | C | S | P | Mn | Si | Ni | Cr | Ti | Al | Co | Mo | W | Fe |

| 3J53 | ≦0.05 | ≦0.02 | ≦0.02 | ≦0.8 | ≦0.8 | 41.5-43 | 5.2-5.8 | 2.3-2.7 | 0.5-0.8 | - | - | - | Bal |

The addition of chromium to these iron-nickel alloys reduces sensitivity to composition but the resulting ternary alloys are still difficult to produce with the desired characteristics and require heavy cold reductions, seriously limiting sizes. The addition of titanium to the iron-nickel-chromium composition produces an alloy with a controllable thermoelastic coefficient, NI-SPAN-C alloy 902. This alloy is melted to the close compositional ranges shown in Table 1. The desired thermoelastic coefficient is then obtained by using cold work and the proper thermal treatment. Cold work produces internal strains, making the coefficient more negative. Thermal treatments, in the lower temperature ranges, relieve strain. They also cause complex ordering phenomena which make the coefficient more positive. Heating at temperatures above about 900°F causes the precipitation of an intermetallic compound of titanium and nickel, withdrawing nickel from the matrix and moving the coefficient further in the positive direction.

Ni-Span C Physical Properties

Density (g/cm3) | Resistivity at 20°C ųΩ•m | Elastic Modulus (E/MPa) | Poisson's Ratio (G/MPa) | Magnetic Frequency (K/106) |

| 8.0 | 1.1 | 176500-191000 | 63500-73500 | 150-250 |

3J53 Alloy Applications in Precision Instruments:

High-Precision Clocks and Watches: Used in components that require minimal thermal expansion and high dimensional stability to ensure accurate timekeeping.

Measuring Instruments: Utilized in gauges, sensors, and other measuring devices where precision and stability are critical.

Magnetic Shields and Components:

Magnetic Shielding: Employed in shielding applications to protect sensitive electronic equipment from external magnetic fields.

Magnetic Cores: Used in high-performance magnetic cores for transformers, inductors, and magnetic amplifiers where high permeability and low coercivity are essential.

Aerospace and Defense:

Aerospace Components: Suitable for high-precision parts in aircraft and spacecraft that require stability under varying thermal conditions.

Defense Systems: Used in sensitive magnetic and electronic components in defense equipment, ensuring reliability and performance in critical applications.

Electronic and Electrical Components:

Relays and Actuators: Employed in devices requiring precise magnetic control and stability.

High-Frequency Transformers: Used in transformers that operate at high frequencies, benefiting from the alloy’s magnetic properties.