Nickel Copper Alloy Bar/Rod 99.95% CuNi Copper Nickel Alloy Sputtering Target/Plate/Strip

- Product Details

| Product Details | |

| Place Of Origin | China |

Brand Name | DLX |

Model Number | CuNi |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

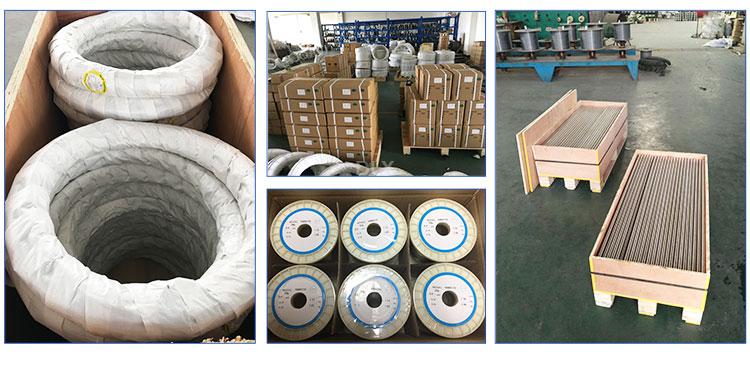

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Specification

Properties/ Material | Resistivity ( 200C μΩ.m) | Max.working temperature ( 0C ) | Tensile strength ( Mpa ) | Melting point ( °C ) | Density ( g/cm³ ) | TCR x10-6 / °C (20~600 °C) | EMF vs Cu (μV/ °C) (0~100 °C) |

| NC003(CuNi1) | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | <8 |

| NC005(CuNi2) | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

| NC010(CuNi6) | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

| NC012(CuNi8) | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

| NC015(CuNi10) | 0.1 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

| NC020(CuNi14) | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

| NC025(CuNi19) | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

| NC030(CuNi23) | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

| NC035(CuNi30) | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

| NC040(CuNi34) | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

| NC050(CuNi44) | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Applications:

One of the main applications of DLX CuNi Alloy is in the marine industry. This alloy is commonly used to manufacture components that are exposed to seawater, such as propellers, heat exchangers, and condensers. Its resistance to corrosion and biofouling makes it ideal for marine applications. DLX CuNi Alloy is also used in oil and gas exploration and production. It is used to make tubing, pipes, and other components that can withstand high pressures and temperatures.

DLX CuNi Alloy is also widely used in power generation. This alloy is used to make components such as heat exchangers, condensers, and boilers that are exposed to high temperatures and pressures. Its thermal conductivity and corrosion resistance make it a popular choice for these applications.

In the chemical processing industry, DLX CuNi Alloy is used to make parts that are exposed to harsh chemicals and high temperatures. The alloy's resistance to corrosion and chemical attack makes it a reliable choice for this industry.

In addition to DLX CuNi Alloy, the DLX brand also offers other alloy products, such as aluminium copper alloy and copper tungsten alloy. These alloys are used in a variety of applications, including aerospace, electronics, and manufacturing.

Support and Services:

CuNi alloy is a highly versatile material used in a wide range of applications. Our technical support team is available to help you with any questions you may have regarding the use, properties, and characteristics of CuNi alloy. We offer a variety of services to support your needs, including: - Material selection guidance - Custom alloy development - Testing and analysis services - Technical consulting Our experienced team of engineers and metallurgists can assist you with any technical challenges you may face, and our state-of-the-art facilities are equipped to handle a range of testing and analysis needs. Contact us to learn more about how we can support your CuNi alloy needs.

Packing and Shipping:

Product Packaging:

Our CuNi alloy products are carefully packed to ensure their safety during transportation. They are usually packaged in wooden cases or pallets with proper cushioning materials to prevent any damage or scratches during transit.

Shipping:

We offer various shipping options to our customers depending on their location and requirements. We work with reliable shipping companies to ensure timely delivery of the products. We also provide tracking information so that our customers can monitor the status of their shipment.

FAQ:

Q: What is DLX CuNi Alloy?

A: DLX CuNi Alloy is a copper-nickel alloy that contains 10-45% nickel and is commonly used in marine applications due to its excellent resistance to seawater corrosion.

Q: What are the benefits of using DLX CuNi Alloy?

A: DLX CuNi Alloy has a number of benefits, including excellent corrosion resistance, high thermal and electrical conductivity, and good ductility and formability. It is also resistant to biofouling, making it ideal for use in seawater environments.

Q: Where is DLX CuNi Alloy manufactured?

A: DLX CuNi Alloy is manufactured in China, where it is produced to the highest standards of quality and consistency.

Q: What applications is DLX CuNi Alloy suitable for?

A: DLX CuNi Alloy is commonly used in marine applications, including piping systems, heat exchangers, and condensers. It is also used in the automotive and aerospace industries, as well as in electrical and electronic applications.

Q: What sizes and forms is DLX CuNi Alloy available in?

A: DLX CuNi Alloy is available in various sizes and forms, including sheets, plates, bars, rods, and tubes. Custom sizes and shapes can also be manufactured to meet specific requirements.

About Us: