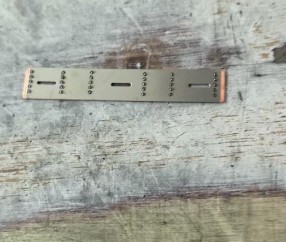

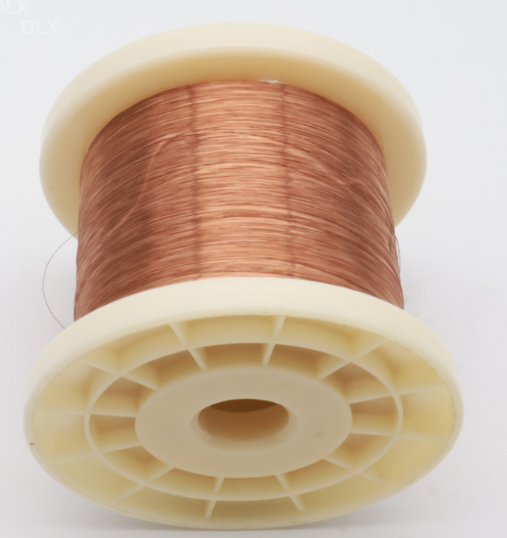

Low Resistance Electric Heating Copper Nickel Alloy For Electrical Heating Cable

- Product Details

Product Description:

The surface of our CuNi alloy product is bright, making it an aesthetically pleasing option for various applications. Its emf Vs Cu is -28 UV/C, which makes it a good choice for temperature measurement applications. Additionally, it is non-magnetic, which is an important feature in applications where magnetic properties can interfere with performance.

Whether you need a copper tungsten alloy or other copper metal products, our CuNi alloy product is an excellent choice. It is highly durable and can withstand the test of time, making it a reliable option for a variety of applications.

Features:

Product Name: CuNi Alloy

Hardness: 120-180 HV

Magnetic Properties: Non-magnetic

Resistivity: 0.12μΩ.m20°C

Density: 8.94 G/cm3

Emf Vs Cu: -28 UV/C

This Copper Alloy Bar, also known as Copper Nickel Alloy or Copper Alloy Rod, features a hardness range of 120-180 HV, non-magnetic properties, resistivity of 0.12μΩ.m20°C, density of 8.94 G/cm3 and an emf vs Cu of -28 UV/C.

Technical Parameters:

| Applications | Marine, Oil & Gas, Power Generation, Chemical Processing |

| Nickel | 23% |

| Elongation | 30-45% |

| Tcr | 50 X10-6/C |

| Emf Vs Cu | -28 UV/C |

| Surface | Bright |

| Hardness | 120-180 HV |

| Condition | Hard / Soft |

| Magnetic Properties | Non-magnetic |

| Material | Cu/Ni |

Applications:

Some of the most common applications for DLX CuNi Wire include:

Marine Industry: This product is ideal for use in the marine industry due to its excellent resistance to saltwater corrosion. It is commonly used in shipbuilding, offshore oil rigs, and other marine applications.

Power Generation: DLX CuNi Wire is also commonly used in power generation applications. Its high electrical conductivity makes it ideal for use in power plant transformers, generators, and other electrical applications.

Electronics: The material's high thermal conductivity makes it ideal for use in electronics. It is commonly used in circuit breakers, relays, and other electronic components.

Automotive Industry: DLX CuNi Wire is also used in the automotive industry. Its high thermal conductivity makes it ideal for use in spark plugs, while its excellent corrosion resistance makes it suitable for use in exhaust systems and other automotive applications.

Medical Industry: This product is also used in the medical industry due to its excellent biocompatibility. It is commonly used in surgical instruments, orthopedic implants, and other medical devices.

In addition to its many applications, DLX CuNi Wire is also available in a range of conditions, including hard and soft. This makes it suitable for use in a variety of scenarios and ensures that it can meet the needs of a wide range of customers.

With a composition of copper and nickel, DLX CuNi Wire is an excellent alternative to other copper metal products. It is also a great alternative to copper tungsten alloy, as it offers similar properties at a lower cost.

Overall, DLX CuNi Wire is a versatile and reliable product that can be used in a wide range of applications. Whether you are in the marine, power generation, electronics, automotive, or medical industry, this product is an excellent choice.

Customization:

DLX offers product customization services for its CuNi Alloy product, also known as Copper Nickel Alloy. Our CuNi Wire is made in China with Cu/Ni material, ensuring high quality and durability. Our standard product has a hardness of 120-180 HV and a bright surface, with a maximum temperature of 350℃ and elongation of 30-45%.

Additionally, we offer customization options for our CuNi Alloy product. We can adjust the hardness, surface, and maximum temperature to fit your specific needs. We can also provide other copper alloys such as Copper Tungsten Alloy, Copper Alloy Plate, and Aluminium Copper Alloy. Contact us for more information on our product customization services.

Support and Services:

Our CuNi alloy product comes with comprehensive technical support and services to ensure optimal performance and reliability. Our team of experts is available to provide guidance on installation, maintenance, and troubleshooting.

We offer a range of services, including:

Custom alloy design and fabrication

Testing and analysis

Product development and optimization

Training and education for customers and partners

Warranty and repair services

Our goal is to provide superior customer service and support, ensuring that our CuNi alloy product meets your specific needs and exceeds your expectations.

Packing and Shipping:

Product Packaging:

The CuNi Alloy product will be packaged securely in a cardboard box with appropriate cushioning materials to prevent any damage during transit. The product will be sealed in a plastic bag to protect it from moisture and other environmental factors. The product specifications and handling instructions will be included in the package.

Shipping:

The CuNi Alloy product will be shipped via a reputable courier service to ensure timely and safe delivery. The shipping cost will be calculated based on the weight and destination of the package. Customers will be provided with a tracking number to monitor the progress of their delivery. We are committed to delivering the product to our customers in the best possible condition.

FAQ:

Q: What is the brand name of the CuNi Alloy product?

A: The brand name of this product is DLX.

Q: What is the model number of the CuNi Alloy product?

A: The model number of this product is CuNi Alloy.

Q: Where is the CuNi Alloy product manufactured?

A: The CuNi Alloy product is manufactured in China.

Q: What is the composition of the CuNi Alloy?

A: The CuNi Alloy is composed of copper and nickel.

Q: What applications is the CuNi Alloy suitable for?

A: The CuNi Alloy is suitable for a variety of applications, including heating elements, resistors, and thermocouples.