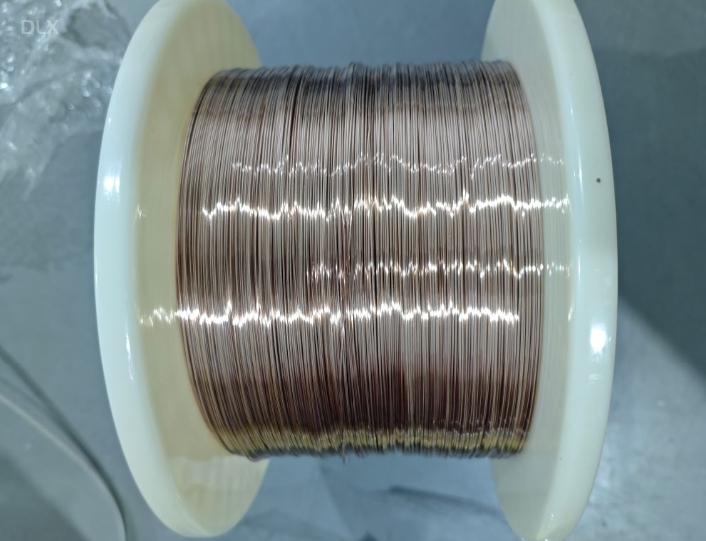

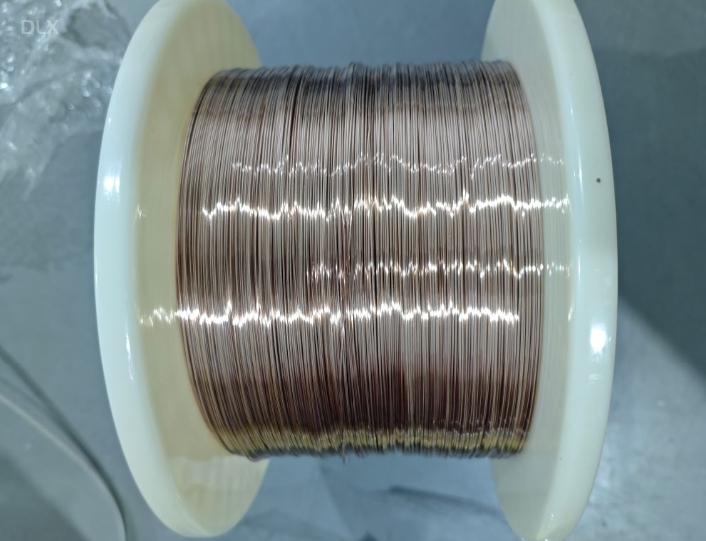

Manganin wire For Precision Resistors

- Product Details

What is Manganin Wire?

Manganin wire is a metallic alloy wire primarily composed of copper (Cu) (about 84-86%), manganese (Mn) (2-4%), and nickel (Ni) (10-12%). It is widely used in electrical applications that require high resistance stability, low temperature coefficient of resistance (TCR), and excellent long-term accuracy.

Key Characteristics of Manganin Wire

Stable Resistance:

Manganin wire exhibits extremely low variation in resistance over a wide range of temperatures, typically between 15°C and 35°C.

Low TCR (Temperature Coefficient of Resistance):

The resistance remains almost constant with changes in temperature, making it ideal for precision applications.

Corrosion Resistance:

Good resistance to oxidation and corrosion under normal environmental conditions.

Thermal EMF Properties:

Generates very low thermal electromotive force (EMF) against copper, which is advantageous in precision measurement applications.

Melting Point and Durability:

The melting point of manganin is around 960°C, and it exhibits good mechanical strength.

Applications of Manganin Wire

Resistors:

Used in low-resistance applications, such as current sensing resistors in power circuits.

Manganin wire is used in standard resistors and shunt resistors where accuracy and long-term stability are critical.

Ideal for power measurement and calibration devices.

Precision Resistors:

Low-Ohmic Resistors:

Electrical Measurement Devices:

Used in strain gauges and Wheatstone bridges due to its stable electrical properties.

Thermal Applications:

Used in environments requiring low heat generation and minimal resistance drift.

Shunts in Ammeter Circuits:

Manganin's low TCR and high stability make it suitable for use in precision shunts that measure high currents.

Temperature Compensation:

Its minimal TCR allows manganin wire to be used as a compensating element in circuits.

Advantages of Manganin Wire

Exceptional Stability: Resistance remains stable over time and under varying temperatures.

Low Thermal EMF: Makes it ideal for high-precision electrical measurement applications.

Durability: Resistant to mechanical wear and tear, as well as corrosion.

Wide Temperature Range: Operates effectively in environments with fluctuating temperatures.

Limitations

High Resistivity:

Manganin has higher electrical resistivity compared to pure copper, which limits its use in high-current applications unless specially designed.

Temperature Range:

While stable in a moderate temperature range, its resistance may drift at extreme high temperatures (above ~200°C) due to microstructural changes.

Cost:

As an alloy, manganin can be more expensive than standard resistance materials like Nichrome or copper.

Physical and Electrical Properties

| Property | Typical Value |

|---|---|

| Resistivity | ~43–48 μΩ·cm |

| Temperature Coefficient | ~±0.00001 / °C (15–35°C) |

| Density | ~8.4 g/cm³ |

| Melting Point | ~960°C |

| Thermal EMF (against Cu) | ~2 μV/°C |

Comparison to Nichrome

| Feature | Manganin | Nichrome |

|---|---|---|

| Stability | Extremely stable resistance | Stable, but less precise |

| TCR | Lower (better for precision) | Moderate |

| Temperature Use | Low to moderate temperatures | High-temperature heating elements |

| Applications | Precision electrical devices | Heating elements |

Manganin wire remains a gold standard for applications requiring precise, stable, and repeatable resistance performance. Let me know if you'd like to explore specific uses or alternatives!