Cheap Price Customized CuNi Copper Nickel Alloy Price CuNi Alloy Copper Nickel Wire for sale

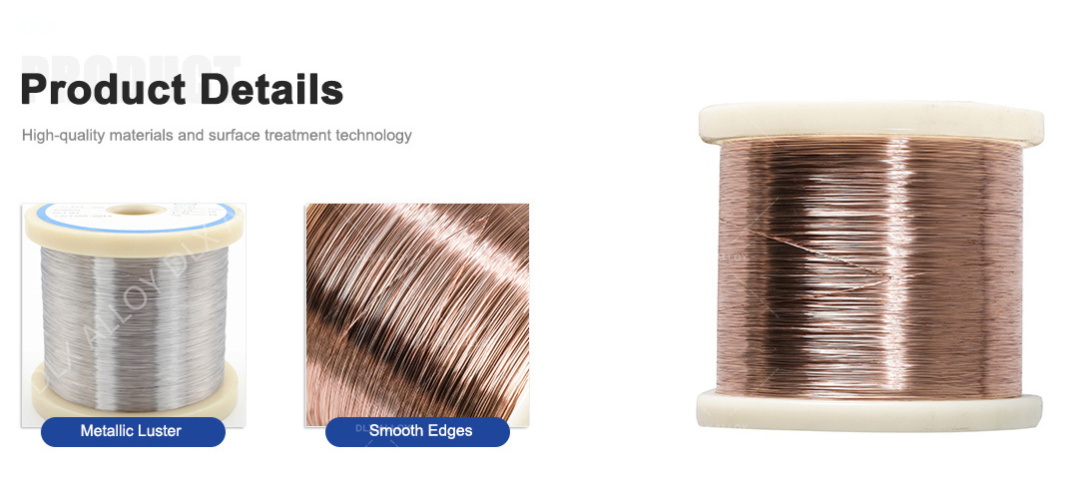

- Product Details

The hardness of our Copper Nickel Alloy ranges from 120 to 180 HV, making it a robust and durable material that can withstand harsh environments. With a maximum temperature of 350℃, our Copper Alloy Rod and Bar can maintain their mechanical properties even in extreme temperatures, making them suitable for high-temperature applications.

Our Copper Nickel Alloy has an elongation of 30-45%, which means it can stretch and flex without breaking, making it an ideal material for applications that require ductility and toughness. Our Copper Alloy Bar and Rod are also highly resistant to erosion, making them suitable for seawater and offshore environments.

Our Copper Nickel Alloy has a density of 8.94 G/cm3, making it a lightweight material that is easy to handle and machine. It also has excellent electrical and thermal conductivity, making it ideal for electrical and heat transfer applications.

In summary, our Copper Alloy Bar and Copper Alloy Rod are high-performance materials that offer excellent corrosion resistance, superior mechanical properties, and outstanding thermal stability. With its excellent ductility, toughness, and erosion resistance, our Copper Nickel Alloy is a versatile material that can be used in a wide range of applications, including Marine, Oil & Gas, Power Generation, and Chemical Processing. Its lightweight, high-strength, and excellent electrical and thermal conductivity properties make it an ideal material for many industrial applications.

Features:

Product Name: CuNi Alloy

Condition: Hard / Soft

Emf Vs Cu: -28 UV/C

Surface: Bright

Maximum Temperature: 350℃

Elongation: 30-45%

Our CuNi Alloy is a high-quality Aluminium Copper Alloy product that is perfect for various applications. As one of the leading Copper Metal Products in the market, we take pride in delivering top-notch Alloy Parts that meet your requirements and exceed expectations. With its hard and soft conditions, bright surface, and maximum temperature of 350℃, our CuNi Alloy is ideal for a wide range of industrial and commercial uses.

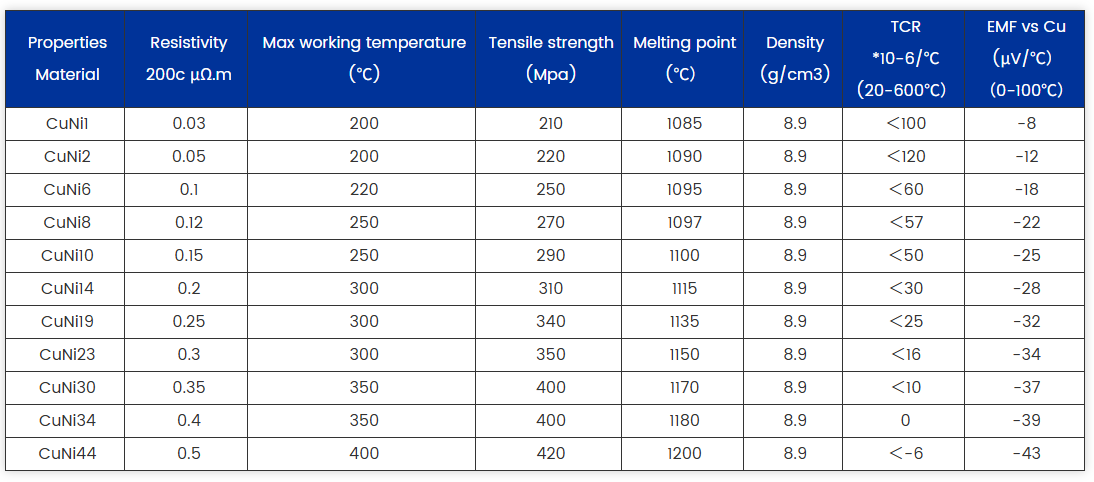

Technical Parameters:

Applications:

The DLX CuNi Alloy Wire is widely used in various industries due to its unique properties. One of the primary applications of this product is in the electrical industry, where it is used to make electrical components such as resistors, heating wires, and thermocouples. The high resistivity of this alloy ensures that it can handle high currents without overheating, making it ideal for use in electrical circuits.

Another application of the DLX CuNi Alloy Wire is in the marine industry, where it is used to make various components such as heat exchangers, condensers, and piping systems. The corrosion resistance of this copper nickel alloy makes it ideal for use in harsh marine environments where other materials are prone to rust and corrosion.

The DLX CuNi Alloy Wire is also used in the automotive industry, where it is used to make various components such as brake lines, fuel lines, and gas tanks. The high temperature resistance of this alloy makes it ideal for use in these applications, where high temperatures and pressure are encountered.

In addition to these applications, the DLX CuNi Alloy Wire is also used in the construction industry, where it is used to make various components such as roofing material, gutters, and downspouts. The durability and corrosion resistance of this copper alloy bar make it ideal for use in these applications, where it is exposed to harsh weather conditions.

In conclusion, the DLX CuNi Alloy Wire is a versatile product that finds its application in various industries due to its unique properties. Its high resistivity, corrosion resistance, and high temperature resistance make it ideal for use in the electrical, marine, automotive, and construction industries.

Customization:

DLX offers a range of product customization services for our CuNi Alloy product. Our CuNi Wire is made from high-quality Cu/Ni material with a hardness of 120-180 HV and a resistivity of 0.12μΩ.m20°C. Its elongation ranges from 30-45%, making it perfect for a wide range of applications, including marine, oil & gas, power generation, and chemical processing.

Our team of experts can help you customize your CuNi Alloy product to meet your specific needs. Whether you require a Copper Alloy Plate, Aluminium Copper Alloy, or Copper Nickel Alloy, we have the expertise and resources to deliver a product that meets your exact specifications.

With DLX, you can trust that your product will be of the highest quality and will be delivered on time and within budget. Contact us today to learn more about our product customization services.

Support and Services:

Our CuNi Alloy product technical support team is dedicated to providing excellent customer service and technical expertise. We offer a range of services including:

Expert advice on product selection and application

Support with product installation and maintenance

Troubleshooting and problem-solving assistance

Product training and education

Customized product solutions

We understand the importance of timely and effective technical support, and our team is committed to providing prompt and reliable service. Whether you have a question about our CuNi Alloy product or need assistance with a technical issue, we are here to help.

Packing and Shipping:

Product Packaging:

The CuNi alloy product will be packed in a secure and sturdy wooden box to prevent any damage during transportation.

The box will be labeled with the product name, weight, and dimensions for easy identification.

A packing slip will be included inside the box with details of the product and quantity.

Product Shipping:

The CuNi alloy product will be shipped via a trusted and reliable courier service.

The shipping charges will be calculated based on the weight and distance of the shipment.

The estimated delivery time will be provided to the customer upon confirmation of the order.

The customer will receive a tracking number to track the shipment until it reaches its destination.

About Us:

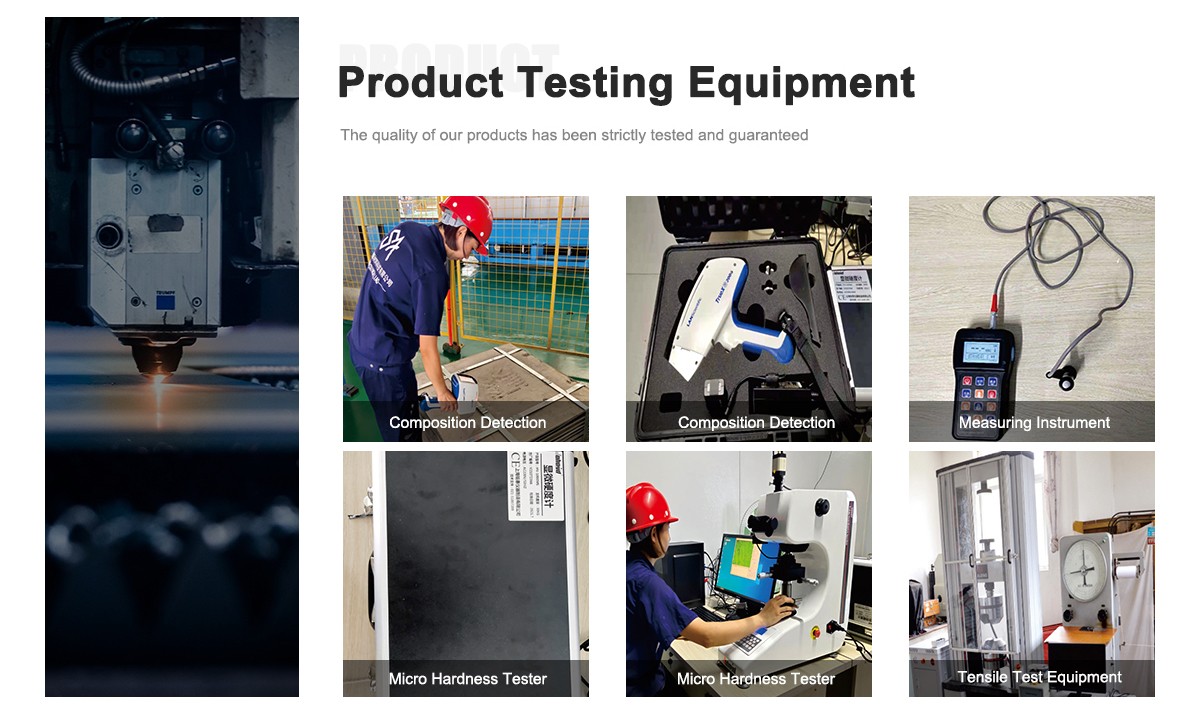

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Here are some frequently asked questions about the DLX CuNi Wire:

Q: What is DLX CuNi Wire?

A: DLX CuNi Wire is a type of copper-nickel alloy wire used in various applications in the electrical and electronics industries. It is known for its high electrical conductivity, good corrosion resistance, and high temperature stability.

Q: Where is DLX CuNi Wire made?

A: DLX CuNi Wire is made in China.

Q: What are the available sizes of DLX CuNi Wire?

A: DLX CuNi Wire comes in a wide range of sizes, from 0.05mm to 10mm in diameter.

Q: What is the maximum operating temperature of DLX CuNi Wire?

A: The maximum operating temperature of DLX CuNi Wire is around 300°C.

Q: What are the typical applications of DLX CuNi Wire?

A: DLX CuNi Wire is commonly used in heating elements, resistors, thermocouples, spark plug electrodes, and other electronic components that require high electrical conductivity and good corrosion resistance.

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now