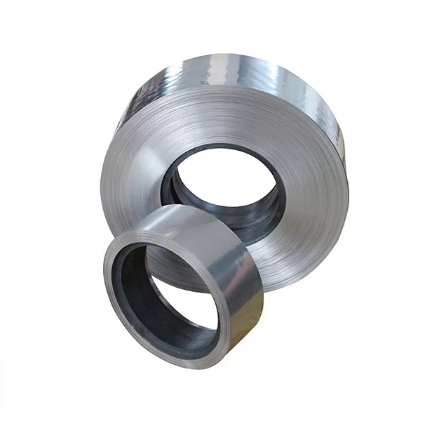

CuNi 44 420 MPA Bright 2.5mmx180mm Resistance Strip CuNi Alloy

| Product Details | |

| Place Of Origin | China |

| Brand Name | DLX |

| Model Number | CuNi44 |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

| Supply Ability | 300 Tons Per Month |

CuNi44, also known as Constantan, is a copper-nickel alloy with approximately 44% nickel content. The alloy you mentioned, "CuNi44 420 MPA Bright 2.5mmx180mm Resistance Strip," appears to be a specific form used for its resistance properties. Here are some detailed characteristics and applications of this alloy:

Properties:

High Electrical Resistivity: CuNi44 has a high electrical resistivity, making it ideal for use in precision resistors and other electrical applications.

Low Temperature Coefficient of Resistance (TCR): This property ensures that the resistance remains stable over a wide range of temperatures.

Good Corrosion Resistance: The alloy exhibits excellent resistance to corrosion, particularly in neutral and mildly aggressive environments.

Mechanical Strength: With a tensile strength of 420 MPa, this alloy strip offers good mechanical properties.

Bright Finish: The bright finish indicates a polished surface, which might be important for certain aesthetic or functional requirements.

Uses:

Precision Resistors: CuNi44 is commonly used in the manufacture of precision resistors due to its stable resistance over a range of temperatures.

Heating Elements: It can be used in heating elements where stable resistance is crucial.

Thermocouples: CuNi44 is often used in thermocouple extension and compensating cables.

Electrical Resistance Wires: Due to its high resistivity, it is used in electrical resistance wires for various applications.

Strain Gauges: The alloy is used in strain gauges because of its consistent resistance characteristics under mechanical strain.

Specific Form - "2.5mmx180mm Resistance Strip":

Dimensions: The strip measures 2.5mm in thickness and 180mm in length.

Application: Such strips are typically used in applications where precise and stable electrical resistance is required. This could include custom resistor manufacturing, specific industrial applications, or experimental setups where exact dimensions and resistance values are crucial.

Overall, CuNi44 is valued for its stable electrical properties and resistance to environmental factors, making it a reliable material for precision electrical components.

Properties/ Material | Resistivity ( 200C μΩ.m) | Max.working temperature ( 0C ) | Tensile strength ( Mpa ) | Melting point ( °C ) | Density ( g/cm³ ) | TCR x10-6 / °C (20~600 °C) | EMF vs Cu (μV/ °C) (0~100 °C) |

| NC003(CuNi1) | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | <8 |

| NC005(CuNi2) | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

| NC010(CuNi6) | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

| NC012(CuNi8) | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

| NC015(CuNi10) | 0.1 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

| NC020(CuNi14) | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

| NC025(CuNi19) | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

| NC030(CuNi23) | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

| NC035(CuNi30) | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

| NC040(CuNi34) | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

| NC050(CuNi44) | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

| Performance | Constantan 6J40 | New Constantan 6J11 | Manganin 6J12 | Manganin 6J8 | Manganin 6J13 | |

| Composition | Ni | 1~2 | 10.5~12.5 | 11~13 | 8~10 | 11~13 |

| Cr | 39~41 | -- | 2~3 | -- | 2~5 | |

| Fe | REST | REST | REST | REST | REST | |

| -- | AI2.5~4.5 Fe1.0~1.6 | -- | Si1~2 | |||

Temperature Range for Components | 5~500 | 5~500 | 5~45 | 10~80 | 10~80 | |

| Density g/cm3 | 8.88 | 8 | 8.44 | 8.7 | 8.4 | |

| Resistivity μΩ.m,20 | 0.48±0.03 | 0.49±0.03 | 0.47±0.03 | 0.35±0.05 | 0.44±0.04 | |

| Extensibivity %∅0.5 | ≥15 | ≥15 | ≥15 | ≥15 | ≥15 | |

| Resistance Temperature Quotiety ∂,10 -6/ | -40~+40 | -80~+80 | -3~+20 | -5~+10 | 0~+40 | |

| Thermoelectromotive force to copper μv/(0~100) | 45 | 2 | 1 | 2 | 2 | |

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.