CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

| Product Details | |

| Place Of Origin | China |

Brand Name | DLX |

Model Number | CuNi Alloy |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Specification

Properties/ Material | Resistivity ( 200C μΩ.m) | Max.working temperature ( 0C ) | Tensile strength ( Mpa ) | Melting point ( °C ) | Density ( g/cm³ ) | TCR x10-6 / °C (20~600 °C) | EMF vs Cu (μV/ °C) (0~100 °C) |

| NC003(CuNi1) | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | <8 |

| NC005(CuNi2) | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

| NC010(CuNi6) | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

| NC012(CuNi8) | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

| NC015(CuNi10) | 0.1 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

| NC020(CuNi14) | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

| NC025(CuNi19) | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

| NC030(CuNi23) | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

| NC035(CuNi30) | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

| NC040(CuNi34) | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

| NC050(CuNi44) | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Product Description:

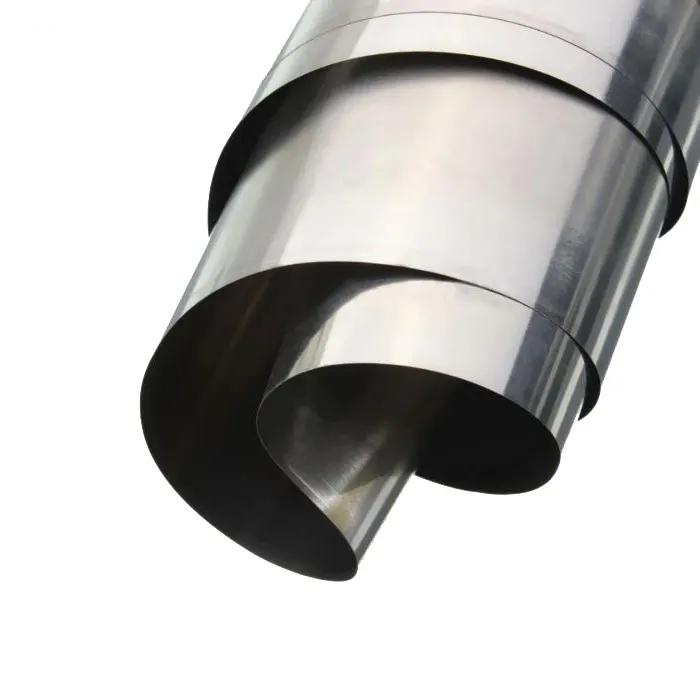

This particular CuNi Alloy is available in both hard and soft conditions, which makes it a versatile material for use in a variety of applications. The hard condition is ideal for applications that require high strength and durability, while the soft condition is ideal for applications that require good formability and flexibility.

The surface of this CuNi Alloy is bright, which gives it an attractive appearance and makes it ideal for use in decorative applications. The bright surface also helps to enhance the corrosion resistance of the material, making it more durable and long-lasting.

This CuNi Alloy has a resistivity of 0.5, which makes it an excellent choice for use in electrical applications. Its high electrical conductivity ensures that it can carry current efficiently, while its low resistivity minimizes energy loss and helps to maintain the overall efficiency of the system.

Overall, the CuNi Alloy is a versatile and reliable material that is widely used in various industrial applications. Its high resistance to corrosion and oxidation, excellent thermal and electrical conductivity, and bright surface make it an ideal choice for a range of different applications. Whether you need a hard or soft material, this copper bronze alloy is sure to meet your needs and exceed your expectations.

Features:

Product Name: CuNi Alloy

Surface: Bright

Sureface: Bright

Condition: Hard / Soft

Composition: Copper And Nickel

Application: Industry

Alloy Steel Material

Copper Powder Metallurgy

Copper Powder Metallurgy

Technical Parameters:

| Technical Parameter | Value |

|---|---|

| Copper Bronze Alloy Composition | Copper And Nickel |

| Purity | High Purity |

| Diameter | 0.1~10mm |

| Maximum Temperature | 200℃ |

| Surface | Bright |

| Corrosion Resistance | Excellent |

| Hardness | 80-120 HV |

| Tensile Strength | 400-600 MPa |

| Emf Vs Cu | -18 UV/C |

Applications:

Copper metal products are widely used in the manufacturing industry, especially in the production of electronic components, such as connectors and switches. Victory's CuNi Alloy can be used in copper powder metallurgy and as a substitute for copper in electronic components. Its high thermal expansion coefficient of 16.5 X 10^-6/K makes it ideal for use in applications where dimensional stability is important, such as in electrical contacts.

Due to its excellent corrosion resistance, CuNi Alloy can also be used in marine applications, such as in the construction of boats and ships. Its bright surface adds an aesthetic appeal to the finished product.

Victory's CuNi Alloy has a maximum temperature of 200℃, making it suitable for use in high temperature applications. It can be used in the automotive industry, specifically in the production of engine parts, where high temperatures are common.

In addition to the above-mentioned applications, CuNi Alloy can also be used in the chemical industry, where it can withstand harsh chemical environments. It can be used in the production of chemical processing equipment, heat exchangers, and storage tanks.

In conclusion, Victory's CuNi Alloy is a highly versatile and reliable copper based alloy product that can be used in a wide range of industries. Its high purity, excellent corrosion resistance, and thermal expansion coefficient make it an ideal choice for many applications, such as in copper powder metallurgy and the manufacturing of electronic components, boats and ships, engine parts, and chemical processing equipment.

Customization:

Our custom product customization services for Victory CuNi Alloy, a copper based alloy steel material, from China, is perfect for industries that require high EMF vs Cu (-18 UV/C) and maximum temperature resistance of up to 200℃. Our CuNi Alloy has a composition of copper and nickel, with a tensile strength of 400-600 MPa. We specialize in copper metal products and can provide customized solutions to meet your specific requirements.

Support and Services:

Our CuNi alloy product is supported by a team of technical experts who can provide assistance with product selection, installation, and maintenance. We also offer a range of services including testing, analysis, and custom fabrication to meet specific customer requirements. Our team is committed to ensuring the highest level of product performance and customer satisfaction.

Packing and Shipping:

Product Packaging:

Each CuNi Alloy product will be packed in a sturdy cardboard box.

The box will be labeled with the product name, quantity, and batch number.

Inside the box, the product will be securely wrapped in bubble wrap or foam to prevent damage during shipping.

Shipping:

All orders will be shipped within 1-2 business days of receiving payment.

Shipping options include standard ground, 2-day, and overnight delivery.

Shipping costs will vary based on the weight and destination of the package.

Customers will receive a tracking number via email once the package has shipped.

International orders may be subject to additional customs fees and taxes.