Hot Sale Nickel Coated Pure Copper Bus Bar 40Mm CuNi Alloy Round Bar for Sale

| Product Details | |

| Place Of Origin | China |

Brand Name | DLX |

Model Number | CuNi Alloy Bar |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Specification

Properties/ Material | Resistivity ( 200C μΩ.m) | Max.working temperature ( 0C ) | Tensile strength ( Mpa ) | Melting point ( °C ) | Density ( g/cm³ ) | TCR x10-6 / °C (20~600 °C) | EMF vs Cu (μV/ °C) (0~100 °C) |

| NC003(CuNi1) | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | <8 |

| NC005(CuNi2) | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

| NC010(CuNi6) | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

| NC012(CuNi8) | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

| NC015(CuNi10) | 0.1 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

| NC020(CuNi14) | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

| NC025(CuNi19) | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

| NC030(CuNi23) | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

| NC035(CuNi30) | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

| NC040(CuNi34) | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

| NC050(CuNi44) | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Product Description:

One of the notable features of our CuNi Alloy is its EMF vs Cu, which is at -18 UV/C. This means that it has a high resistance to corrosion and can withstand extreme temperatures, making it suitable for use in harsh environments.

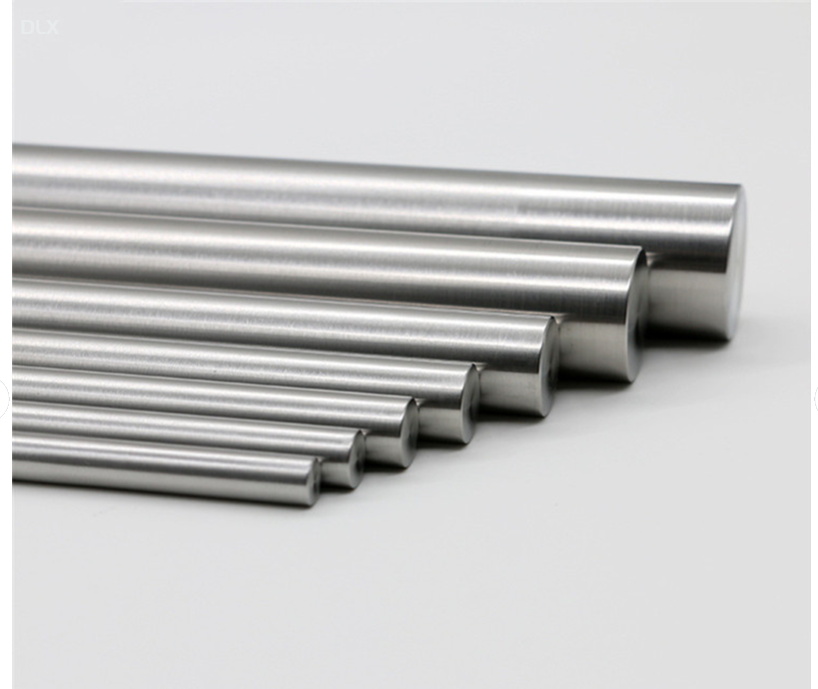

In terms of appearance, our CuNi Alloy has a bright surface that is visually appealing. It is easy to work with and can be fabricated into different shapes and sizes to suit various industrial needs.

Our CuNi Alloy is widely used in the industry due to its excellent corrosion resistance and high resistivity. It is commonly used in marine applications, heat exchangers, and other applications where resistance to corrosion and extreme temperatures is crucial.

Our CuNi Alloy has a resistivity of 0.5, which makes it an excellent conductor of heat and electricity. This property makes it suitable for use in electrical applications where high conductivity is required.

In summary, our CuNi Alloy is a top-quality alloy steel material that is highly resistant to corrosion and extreme temperatures. It has a bright surface that is visually appealing and can be fabricated into different shapes and sizes to suit various industrial needs. Its high resistivity and excellent conductivity make it ideal for use in electrical applications. If you are looking for a reliable and durable alloy steel material for your industrial needs, our CuNi Alloy is an excellent choice.

Features:

Product Name: CuNi Alloy

Diameter: 0.1~10mm

Maximum Temperature: 200℃

Purity: High Purity

Hardness: 80-120 HV

Tensile Strength: 400-600 MPa

Copper Alloy Tube

Copper Nickel Alloy

Inconel Nickel Alloy

Technical Parameters:

| Composition | Copper And Nickel |

| Hardness | 80-120 HV |

| Surface | Bright |

| Corrosion Resistance | Excellent |

| Tensile Strength | 400-600 MPa |

| Application | Industry |

| Purity | High Purity |

| Resistivity | 0.5 |

| Thermal Expansion Coefficient | 16.5 X 10^-6/K |

| Emf Vs Cu | -18 UV/C |

This Copper Nickel Alloy is made using Copper Powder Metallurgy and is also known as Copper Bronze Alloy.

Applications:

The bright surface of the CuNi Alloy adds to its appeal, making it a sought-after material in industries such as marine, power generation, and chemical processing. DLX's CuNi Alloy has a diameter range of 0.1~10mm, which makes it suitable for various applications.

Inconel Nickel Alloy finds its use in various applications, including heat exchangers, condensers, boat hulls, and sea water desalination plants. Its resistance to corrosion by seawater makes it an excellent choice for marine and offshore applications. Its high resistance to oxidation makes it an ideal solution in the chemical processing industry.

Additionally, the CuNi Alloy has a low Emf vs Cu (-18 UV/C), which makes it suitable for use in electrical applications. Its low resistivity (0.5) makes it an ideal material for use in resistance wires.

The DLX CuNi Alloy finds its use in a wide range of products and industries. Some of its applications include:

Marine and Offshore: The CuNi Alloy finds its use in the manufacturing of boat hulls, heat exchangers, and condensers due to its excellent resistance to seawater corrosion.

Power Generation: The CuNi Alloy is used in power plants for heat exchangers and condensers due to its high thermal conductivity.

Chemical Processing: The CuNi Alloy is used in chemical processing plants due to its high resistance to oxidation and corrosion.

Resistance Wires: The low resistivity of the CuNi Alloy makes it an ideal material for use in resistance wires for heating elements.

In conclusion, DLX's CuNi Alloy is a versatile material that finds its use in a wide range of applications due to its excellent attributes. Its resistance to corrosion, high thermal conductivity, low resistivity, and bright surface make it an ideal solution for various environments and industries.

Customization:

Looking for customizations for your Copper Bronze Alloy product? Look no further than DLX's CuNi Alloy line, originating from China. With excellent corrosion resistance and a maximum temperature of 200℃, these wires (available in diameters ranging from 0.1mm to 10mm) are perfect for a variety of applications. Plus, their bright surface and density of 8.94 G/cm3 make them a top choice for those seeking high-quality Copper Bronze Alloy, Copper Bronze Alloy, or Aluminium Copper Alloy products. Contact us today to learn more about our product customization services!

Support and Services:

Our CuNi alloy products are designed to meet the highest standards of quality and performance in various applications. We offer comprehensive technical support services to ensure that our customers can maximize the benefits of our products. Our team of experienced engineers and technicians is available to assist customers with product selection, installation, operation, and maintenance. We also provide troubleshooting and repair services to help customers address any issues that may arise with our products.

In addition, we offer various training programs to help customers enhance their knowledge and skills related to our products. Our training programs cover topics such as product features, performance characteristics, and best practices for installation, operation, and maintenance. We also provide customized training programs to meet specific customer needs.

Our commitment to customer satisfaction extends beyond the sale of our products. We offer a range of after-sales services to ensure that our customers can continue to receive the support they need throughout the product lifecycle. Our after-sales services include spare parts supply, repair and refurbishment services, and technical advice and support.

Packing and Shipping:

CuNi Alloy Product Packaging:

All CuNi alloy products are carefully wrapped and packaged to ensure they arrive in excellent condition.

Each product is placed in a protective plastic bag to prevent scratches and tarnishing.

The bagged product is then placed in a sturdy cardboard box with protective padding to prevent damage during shipping.

The box is sealed with strong adhesive tape to ensure it remains securely closed during transit.

CuNi Alloy Product Shipping:

All orders for CuNi alloy products are shipped within 2 business days of receiving payment.

We offer worldwide shipping via our trusted shipping partners.

Shipping times will vary depending on the destination, but we aim to deliver all orders within 7-14 business days.

Customers will receive a tracking number via email once their order has been shipped, so they can track their package online.

If there are any issues with shipping or delivery, please contact us and we will do our best to resolve the issue as quickly as possible.

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is DLX.

Q: What is the model number of this product?

A: The model number of this product is CuNi Alloy.

Q: Where is this product manufactured?

A: This product is manufactured in China.

Q: What are the applications of this product?

A: CuNi Alloy is commonly used in marine environments, power generation plants, and chemical processing industries due to its excellent corrosion resistance and high thermal conductivity.

Q: What are the available sizes and forms of this product?

A: CuNi Alloy is available in various sizes and forms such as round bars, sheets, pipes.