5 years of cooperation with Italian customer case: pure nickel strip solution for new energy battery

Release time:2025-12-17 Strike:1074 Inquire Now

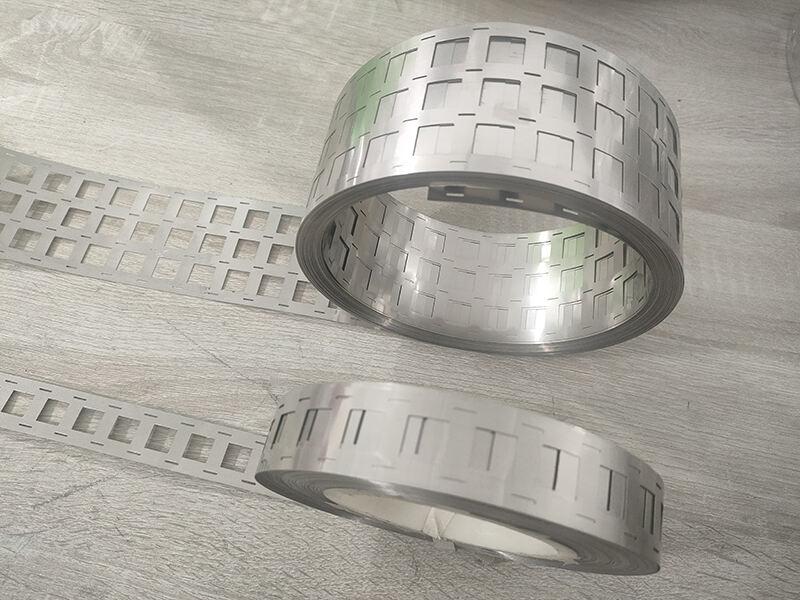

Pure nickel strip solution for new energy battery connection

Customer demand The customer is a new energy battery manufacturer, mainly producing lithium battery modules. They needed a high-purity nickel strip material for the connection of battery modules, and specific requirements included: High conducti...

Customer demand

The customer is a new energy battery manufacturer, mainly producing lithium battery modules. They needed a high-purity nickel strip material for the connection of battery modules, and specific requirements included:

High conductivity: To ensure the conductivity of the battery connection, reduce internal resistance, improve efficiency.

Corrosion resistance: No oxidation or corrosion on the surface under high humidity and long-term use environment.

High strength and flexibility: it can withstand mechanical pressure and is easy to process and weld.

Specifications accurate: width, thickness and other dimensional accuracy control within ±0.01mm.

Our solution

According to the needs of our customers, we provide the following solutions

Material selection

Industrial grade pure nickel strips of ≥99.6% purity are recommended to ensure electrical conductivity and corrosion resistance.

Process optimization

Cold rolling and precision annealing processes increase material strength and flexibility while ensuring surface finish.

Customized production

According to customer requirements to provide a variety of specifications of nickel tape, width of 10mm, 15mm, thickness of 0.1mm, 0.2mm.

Testing and certification

Provide electrical conductivity test reports and corrosion salt spray test reports to ensure that materials meet customer technical requirements.

Key technical parameters

Material: Pure nickel (≥99.6%)

Thickness: 0.1mm / 0.2mm

Width: 10mm / 15mm

Resistivity: ≤9.8 μΩ·cm

Tensile strength: ≥400 MPa

Corrosion resistance: No obvious corrosion in 1000 hours at high humidity (95%RH)

Delivery and service

Delivery: The first batch of 100 kg pure nickel strips will be provided in two sizes with a lead time of 18 days.

Services:

Provide suggestions on welding performance optimization to improve customer productivity.

Online support customers to solve the problems in the welding of nickel strip and battery.

Regular return visit to understand the actual use effect of the product in the battery module.

Customer feedback

Performance evaluation: The customer said that the pure nickel strip performed well in mass production, greatly improved welding efficiency and stability, and significantly improved the overall performance of the battery module.

Quality stability: Dimensional accuracy and surface finish meet the requirements of automation equipment and reduce the production loss rate.

-

Spring Festival from 2025-01-25 to 2025-02-05

Introduction to Chinese Spring Festival and Its Impact on Produc...

-

Iranian customers, customized alloy solutions for the chemical industry

...

-

Indian customer: Corrosion resistant high-performance titanium alloy for Marine engineering

...

-

What is the best thickness wire for welding?

The best thickness of wire for welding depends on several factor...